Light emitting diode module group

A technology of light-emitting diodes and modules, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of general products without structure and inconvenience, and achieve the effect of reducing steps and time, assisting heat dissipation, and ensuring light-emitting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

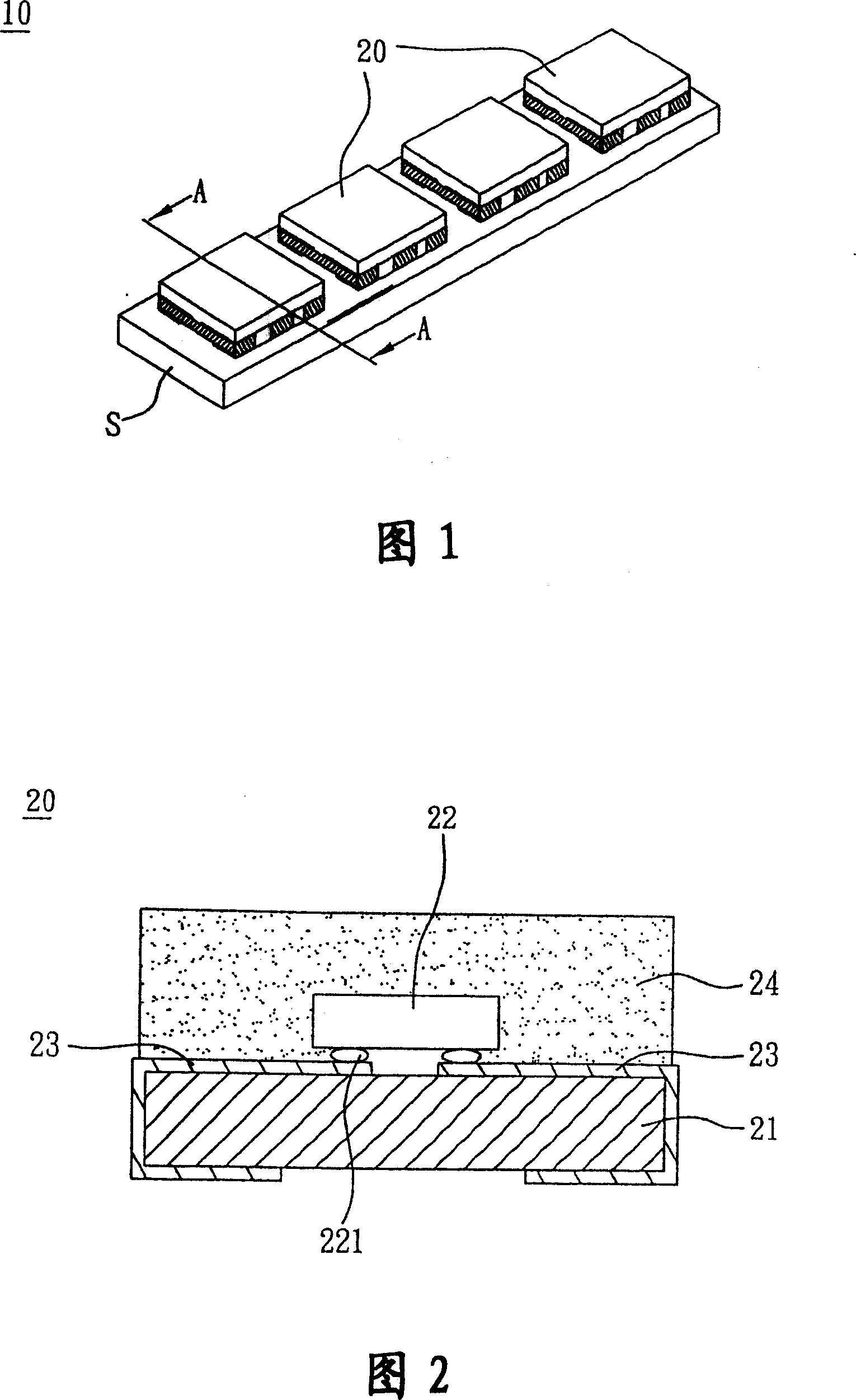

[0063] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the light-emitting diode module proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

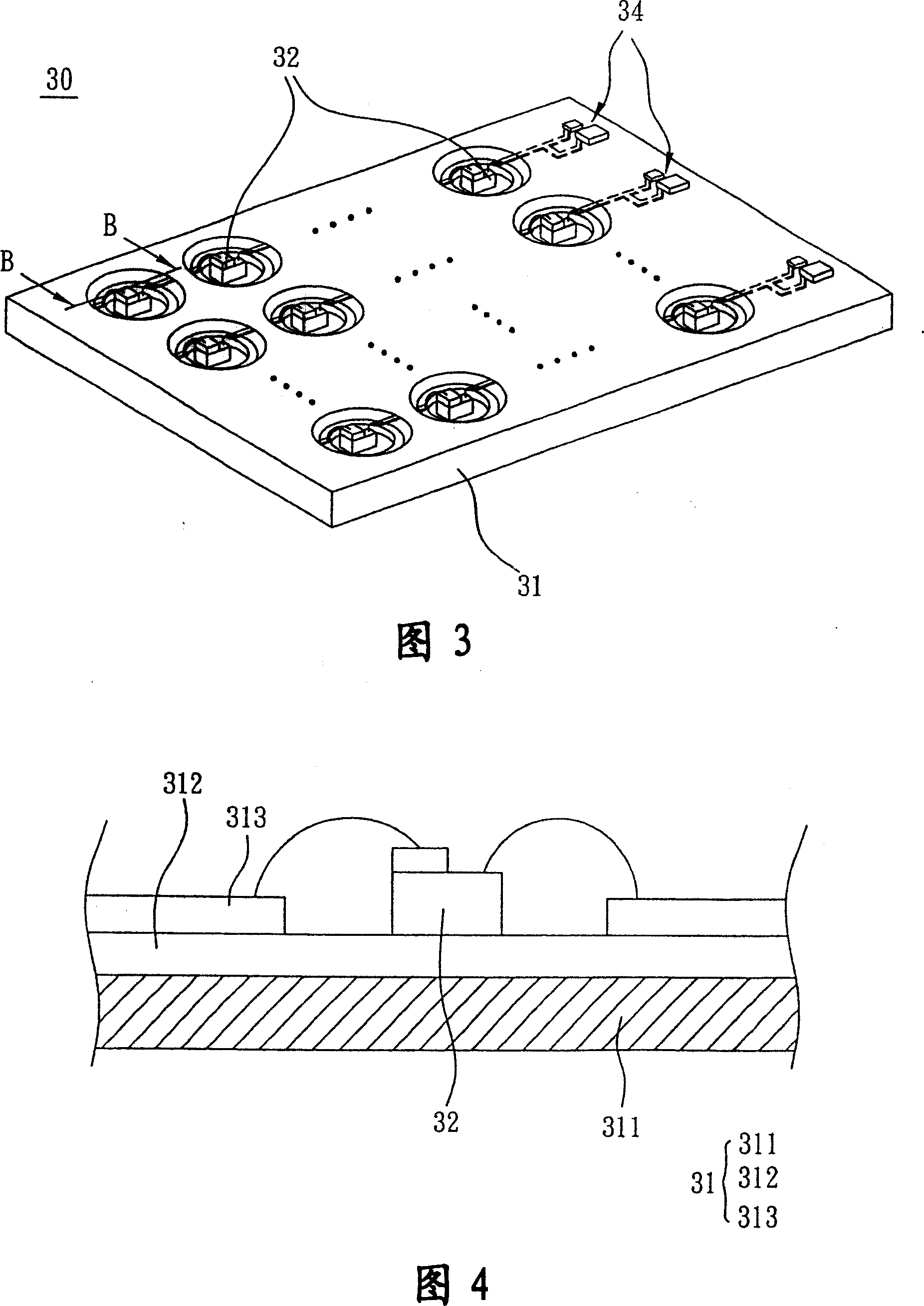

[0064] Please refer to FIG. 3 , the LED module 30 includes a metal circuit substrate 31 and a plurality of LED dies 32 . It should be noted that the number and arrangement of the LED chips 32 in the LED module 30 are not limited. In this embodiment, the light emitting diode dies 32 are arranged in an array as an example, of course, each light emitting diode die 32 may also be arranged in a straight line.

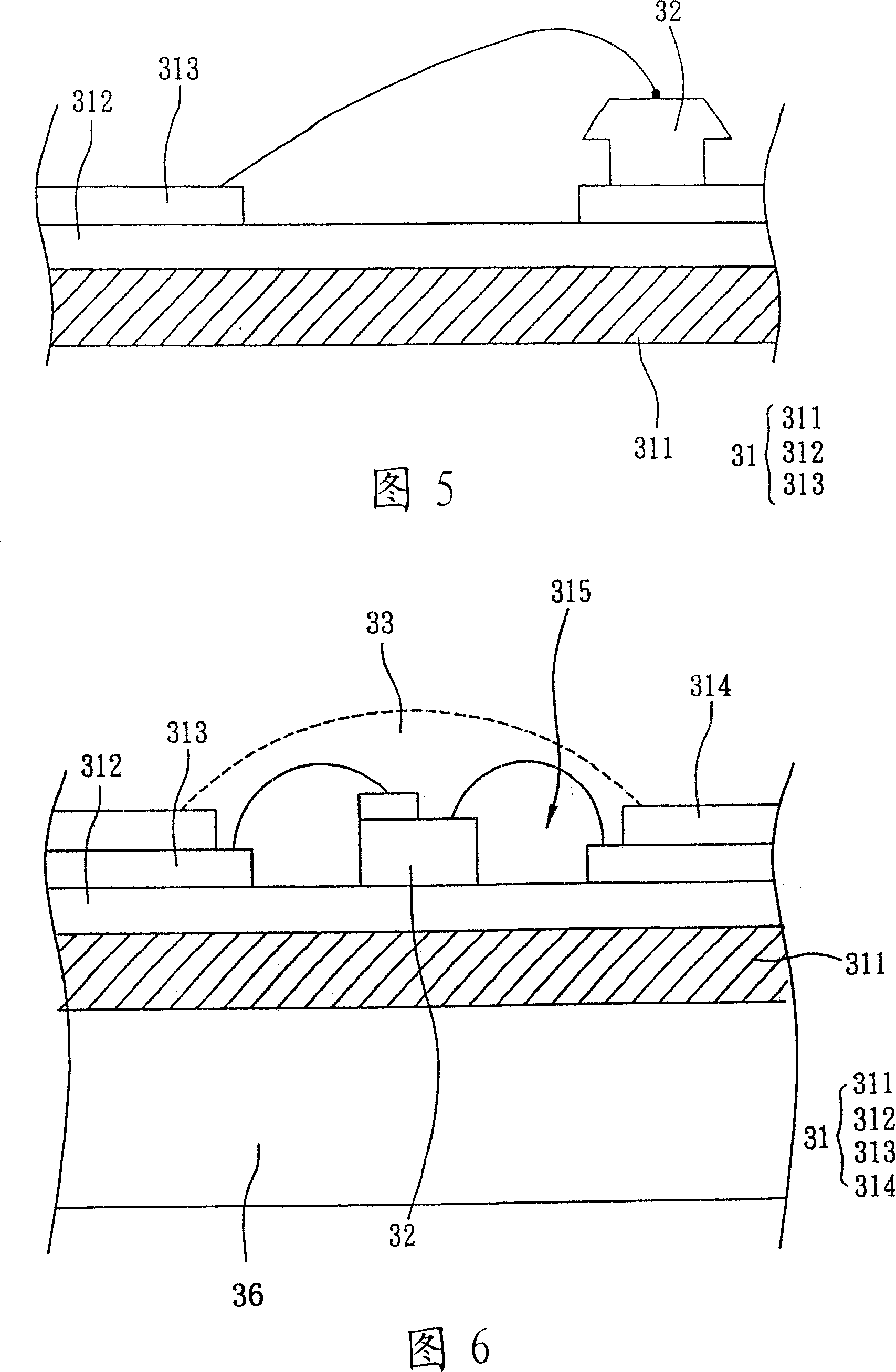

[0065] Please refer to FIG. 3 and FIG. 4 at the same time. FIG. 4 is a schematic cross-sectional view along the line B-B in FIG. The metal circuit substrate 31 sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com