Earth axis type solar furnace optical collector

A solar furnace and concentrator technology, which is applied to solar collectors, solar collector controllers, solar thermal devices, etc., can solve the problems of unsatisfactory light concentrating effect, affecting collection efficiency, and small scale of solar furnaces. Achieve the effect of low cost, high utilization efficiency and increased scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

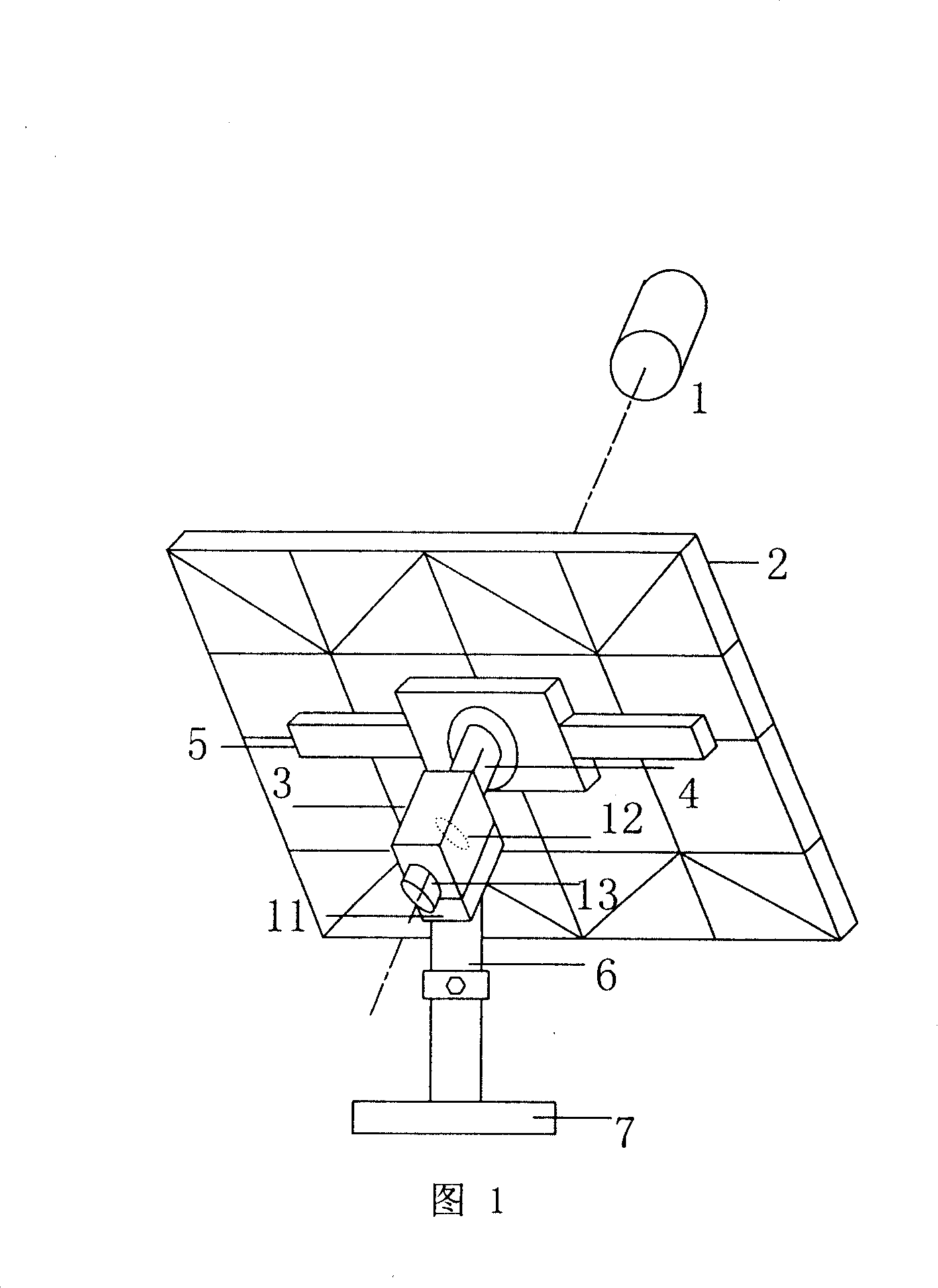

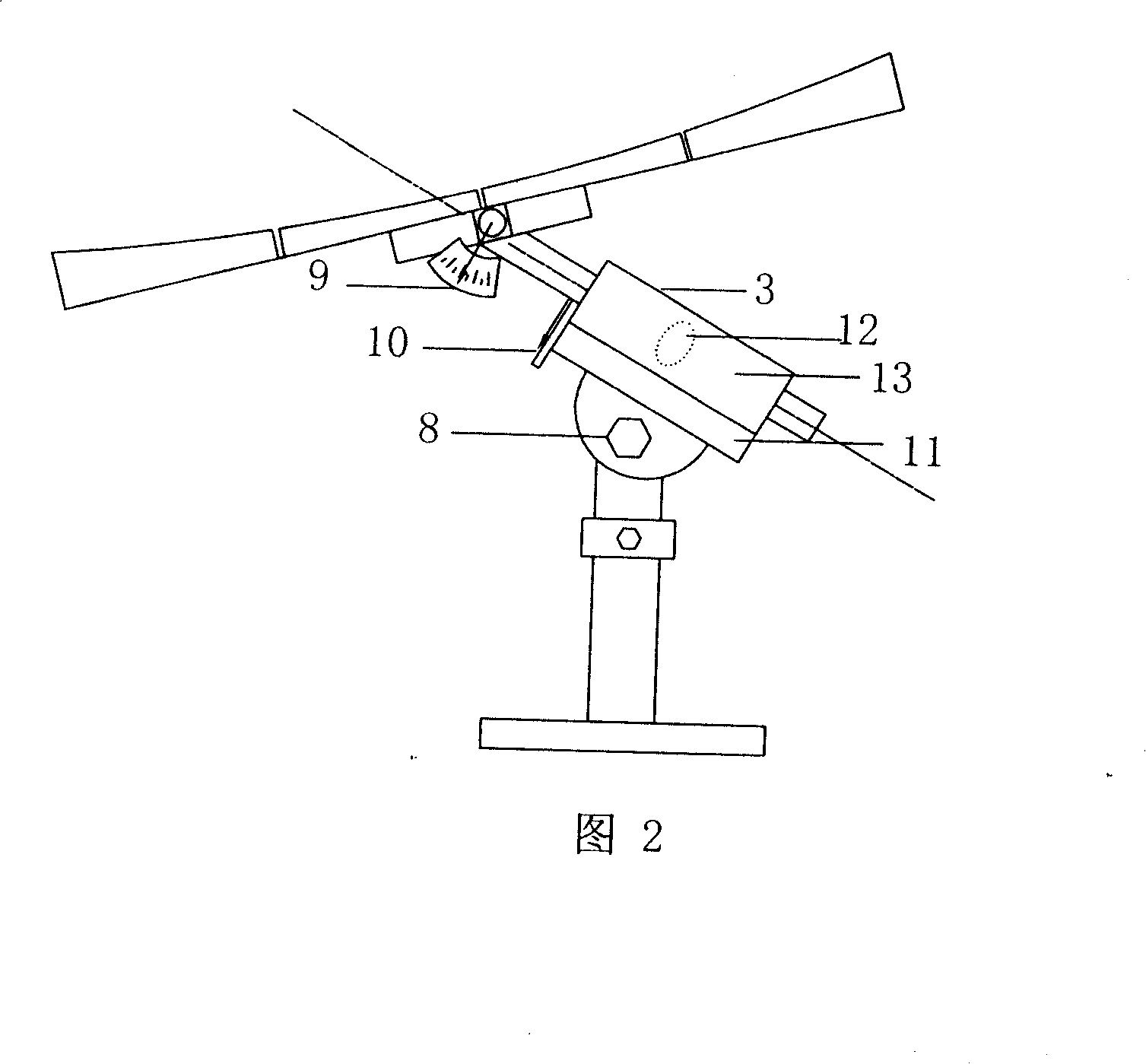

[0027] According to the specific application situation, according to the attached drawings 1, 2, 3, design and manufacture the condenser, and then install and debug.

[0028] 1. Production of the tire surface: The tire surface is a special cylindrical surface. The production method is similar to that of the rotating paraboloid. First, the tire surface scraper curve is made according to the designed tire surface surface formula, and then the tire mold is made by using the scraper. The scraper on the tire surface moves along a fixed track to make the punch. The track is a circular arc whose curvature is equal to that of the sagittal section of the tire surface. Use the prepared convex mold to make the condenser lens. For the condenser lens with a large area, adopt the method of block production, and connect each small piece with a steel bracket on the back of the mirror body. The mirror body can be disassembled and folded, which is convenient for transportation and transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com