Automatic material clamping mould unloading device of vehicle right and left wheel arc cover

A technology of left and right wheels and arc cover, applied in the field of mechanical structure, can solve the problems of high labor intensity of workers, difficult to release semi-finished products, easy to scratch fabrics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

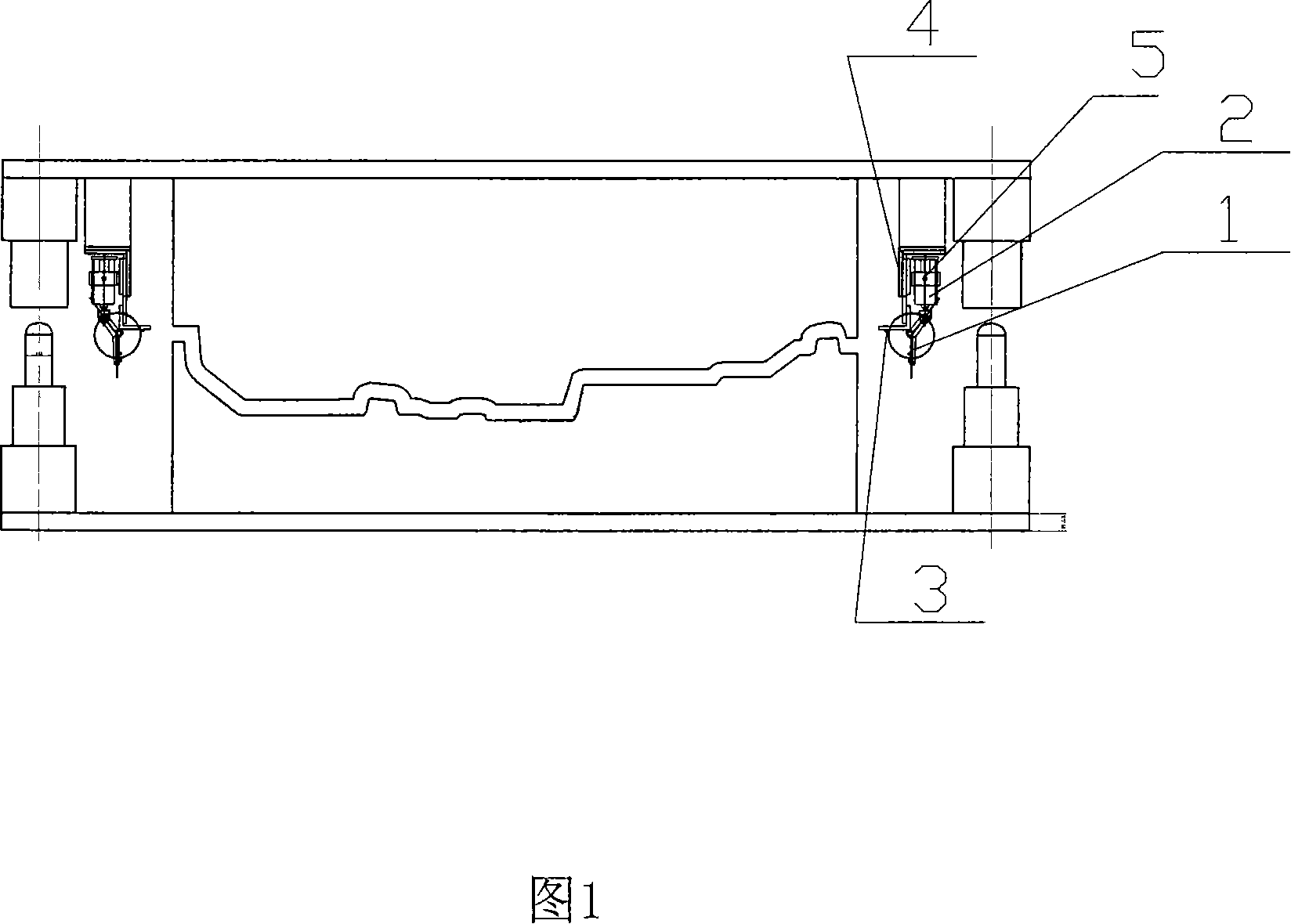

[0010] The present invention is mainly made up of lower fixture 1, cylinder 2, upper fixture 3, outer support seat 4, cylinder connection swing seat 5. The present invention adopts lower clamp 1 and upper clamp 3 to be connected on the outer support seat 4 respectively, and the cylinder 2 is fixed on the cylinder connecting swing seat 5 .

[0011] The invention adopts a thin air cylinder as a power source, and realizes the action of grasping and clamping materials through a connecting rod structure. The clamping mechanism is fixed at the four corners of the upper mold. With the movement of the press up and down, the fixture clamps the four corners of the workpiece, lifts the workpiece with the upper mold, and controls the cylinder 2 at the four corners of the upper mold to drive the lower fixture 1 to clamp the workpiece. As the upper mold rises, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com