Molding mold of wall heat preserving formwork

A technology for forming molds and mold shells, which is applied in the direction of molds, etc., can solve problems such as the advent of mold shells and undiscovered wall constructions, and achieve the effects of easy mold opening and closing, reasonable structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

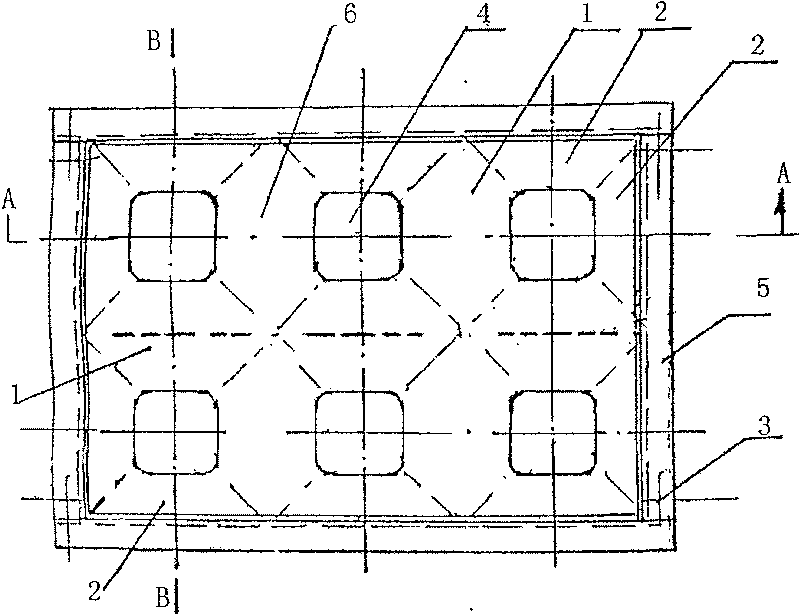

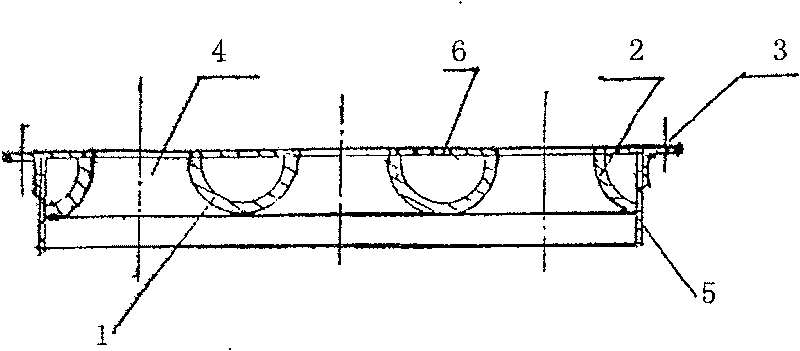

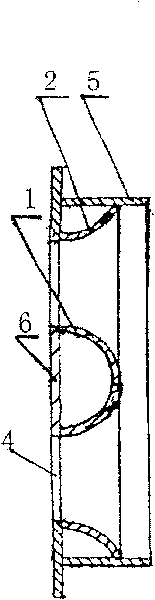

[0019] The content of the present invention is described in detail in conjunction with the accompanying drawings through the embodiment, as figure 1 Shown is the schematic diagram of the main view of the present invention, the four corners of the mold frame 5 are provided with connecting screw holes 3 connected with the supporting molding machine, and in the mold frame 5, three pairs of injection ports 4 are arranged side by side symmetrically up and down. An arc-shaped module 1 with a closed semicircular cross-section is provided between every two injection ports 4 in the row, and a transition plate 2 is provided between the upper and lower edge sides of the injection port 4 and the sides of the left and right ends and the frame, And above the curved module 1 and the transition plate 2, a cover plate 6 is provided, which is on the same plane as the upper port of the injection port 4. figure 2 As shown, the lower part of the mold frame 5 forms a cavity with a rectangular sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com