Method of amphipathic nature fluorine-contained copolymer modifying surface of polytetrafluoroethylene porous membrane

A polytetrafluoroethylene, surface modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of shortened membrane life, low surface energy, low water flux, etc. The effect of large-scale industrial production, improved anti-pollution performance, and simple coating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Wash hexafluorobutyl methacrylate and oxyethylene methacrylate with 5% NaOH for 3 times, then wash with deionized water to pH 7, and then add calcium hydride to store for 24 hours, N, N '-Dimethylformamide is added to calcium hydride and stored for 24 hours, and the above reagents are stored under reduced pressure and distillation;

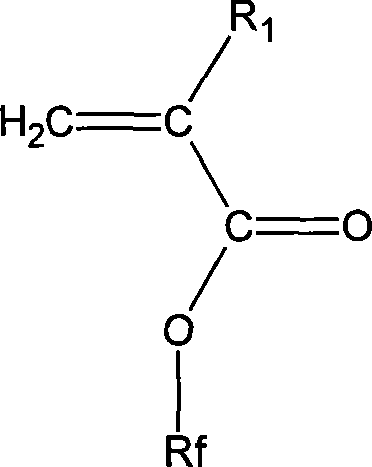

[0043] 2. Dissolve 1 mol of purified hexafluorobutyl methacrylate and 0.5 mol of oxyethylene methacrylate in an equal volume of polar solvent N, N'-dimethylformamide, and add 1 / 600 dibenzoyl peroxide, reflux for 6 hours, and precipitate in petroleum ether. After filtering and washing, vacuum drying treatment.

[0044] 3. The random copolymer of hexafluorobutyl methacrylate and oxyethylene methacrylate purified in the above step is dissolved in water.

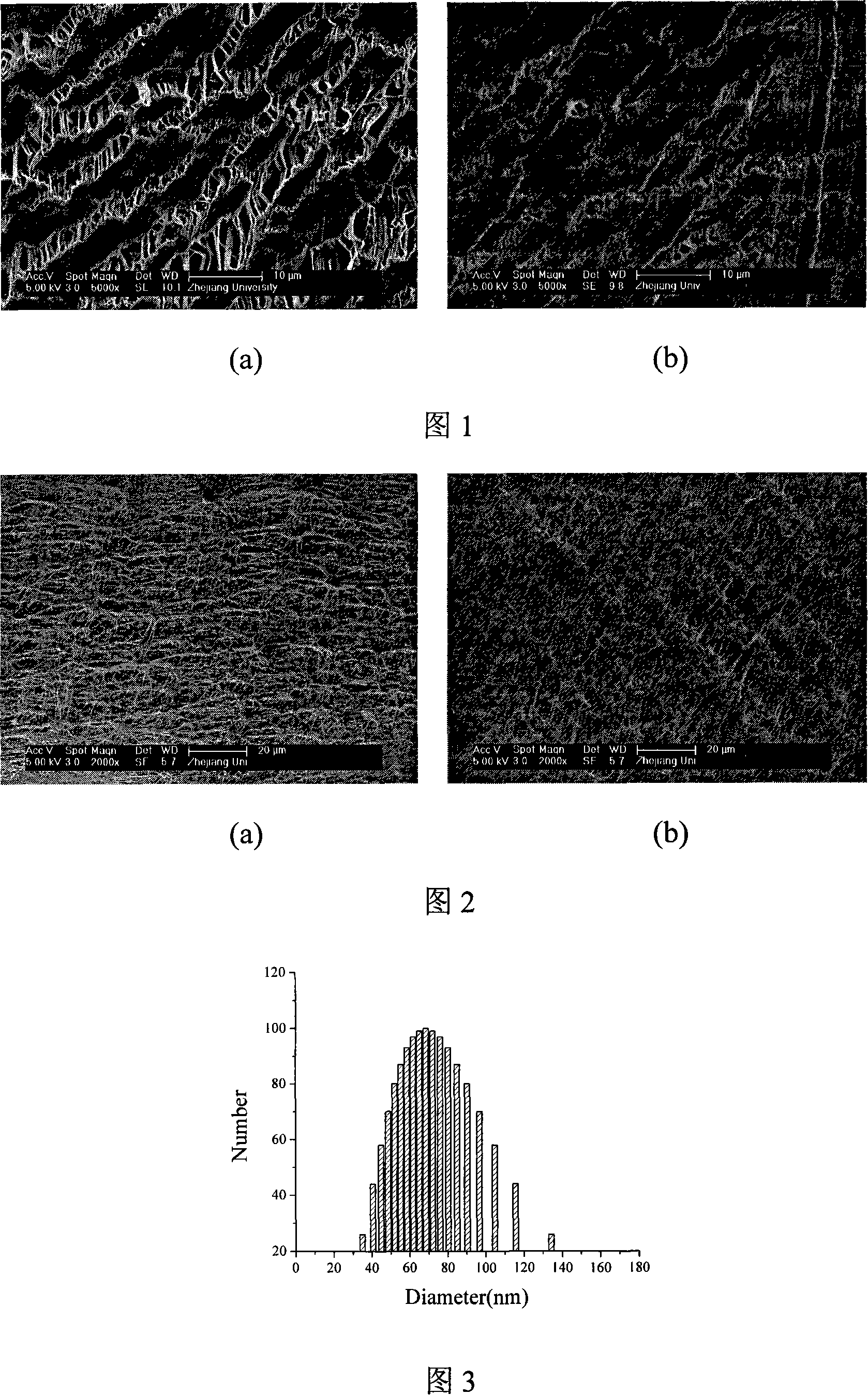

[0045] 4. Coat the solution prepared in the above steps on the upper and lower surfaces of a 20×10 cm uniaxially stretched polytetrafluoroethylene flat porous membrane at a coating temperatur...

Embodiment 2

[0048] 1. Dissolve hexafluorobutyl methacrylate in N,N'-dimethylformamide under argon atmosphere, the solution concentration is 25%, and add ethyl α-bromopropionate and cuprous bromide With bipyridine, the ratio of the three is 1:1:3, cuprous bromide is 1 / 200 of the monomer, freeze with liquid nitrogen, vacuum to remove oxygen, thaw, repeat twice, move into 45℃ oil bath and stir 48 hours;

[0049] 2. Precipitate the product of step 1 in an excess of absolute ethanol, dissolve and precipitate for several times and then vacuum dry, dilute, filter with a chromatographic column, filter by precipitation, and vacuum dry to constant weight at 25°C;

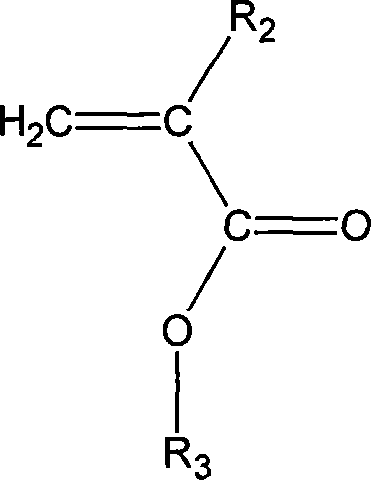

[0050] 3. Dissolve the product of step 2 and oxyethylene methacrylate in N,N'-dimethylformamide under nitrogen atmosphere, the solution concentration is 25%, add cuprous bromide and bipyridine, the ratio of the two 1:3, cuprous bromide is 1 / 300 of the monomer, freeze with liquid nitrogen, vacuum to remove oxygen, thaw, repeat 4 times, move i...

Embodiment 3

[0055] 1. Dissolve oxyethylene methacrylate in N,N'-dimethylformamide under a nitrogen atmosphere, the solution concentration is 75%, add ethyl α-bromopropionate, cuprous chloride, and Dipyridine, the ratio of the three is 1:1:3, cuprous chloride is 1 / 200 of the monomer, freeze with liquid nitrogen, vacuum to remove oxygen, thaw, repeat twice, move into an oil bath and stir for 4 hours. The bath temperature is 90℃;

[0056] 2. Precipitate the product of step 1 in an excess of anhydrous methanol, dissolve and precipitate it for several times, and then vacuum dry, dilute, filter with a chromatography column, filter by precipitation, and vacuum dry at 25°C to constant weight;

[0057] 3. Dissolve the product of step 2 and hexafluorobutyl methacrylate in N,N'-dimethylformamide under an argon atmosphere, the solution concentration is 75%, add cuprous chloride and bipyridine, two The ratio is 1:3, cuprous chloride is 1 / 300 of the monomer, freeze with liquid nitrogen, vacuum to remove ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com