Coal mine inert gas foam extinguishing system

An inert gas and foam fire extinguishing technology, which is applied in fire rescue and other fields, can solve unresolved and troubled coal mine safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

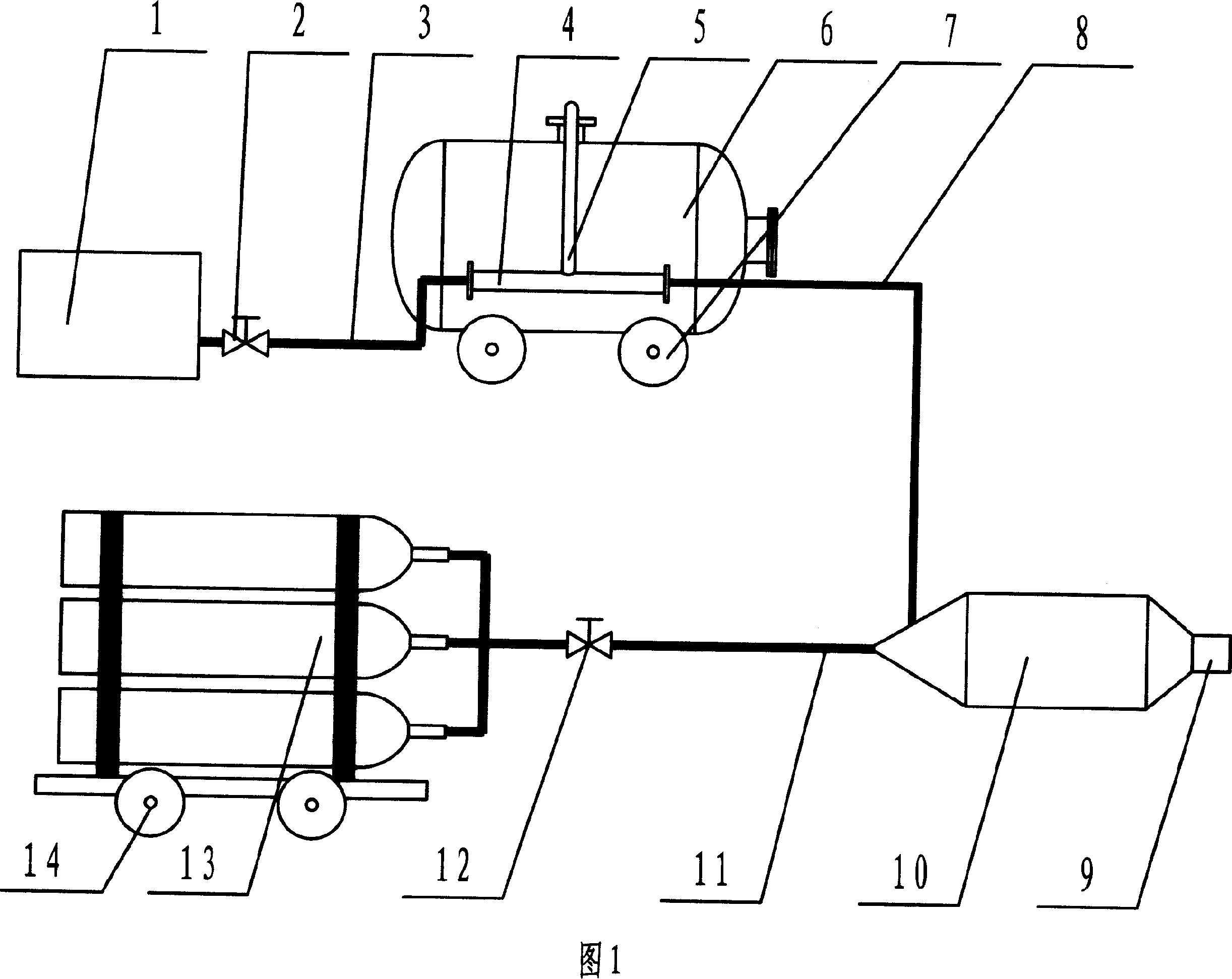

[0010] Connect the pressure water source (1) with the water source shut-off valve (2) to the pressure water delivery pipe (3), and the other end of the pressure water delivery pipe (3) is connected to the proportional mixer (4); there is foam on the proportional mixer (4) Stock solution pipeline (5), foam stock solution pipeline (5) communicates with foam liquid storage tank (6), and foam stock solution can enter proportional mixer (4) through foam stock solution pipeline (5) from foam liquid storage tank (6); The water that enters the proportional mixer (4) from the water delivery pipe (3) and the foam stock solution that enters the proportional mixer (4) from the foam stock solution pipeline (5) become a foam mixture after being mixed by the proportional mixer (4), and then pass through The foam mixed liquid pipeline (8) is imported into the inert gas generator (10); the inert gas source (13) is arranged on the gas source car (14), and the inert gas source (13) is a group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com