Pore structure modulating through-hole porous aluminum and aluminum alloy and preparation method thereof

A technology of aluminum alloy and porous aluminum, applied in the field of porous aluminum and aluminum alloy and its preparation, to achieve the effect of good sound absorption performance and excellent noise reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

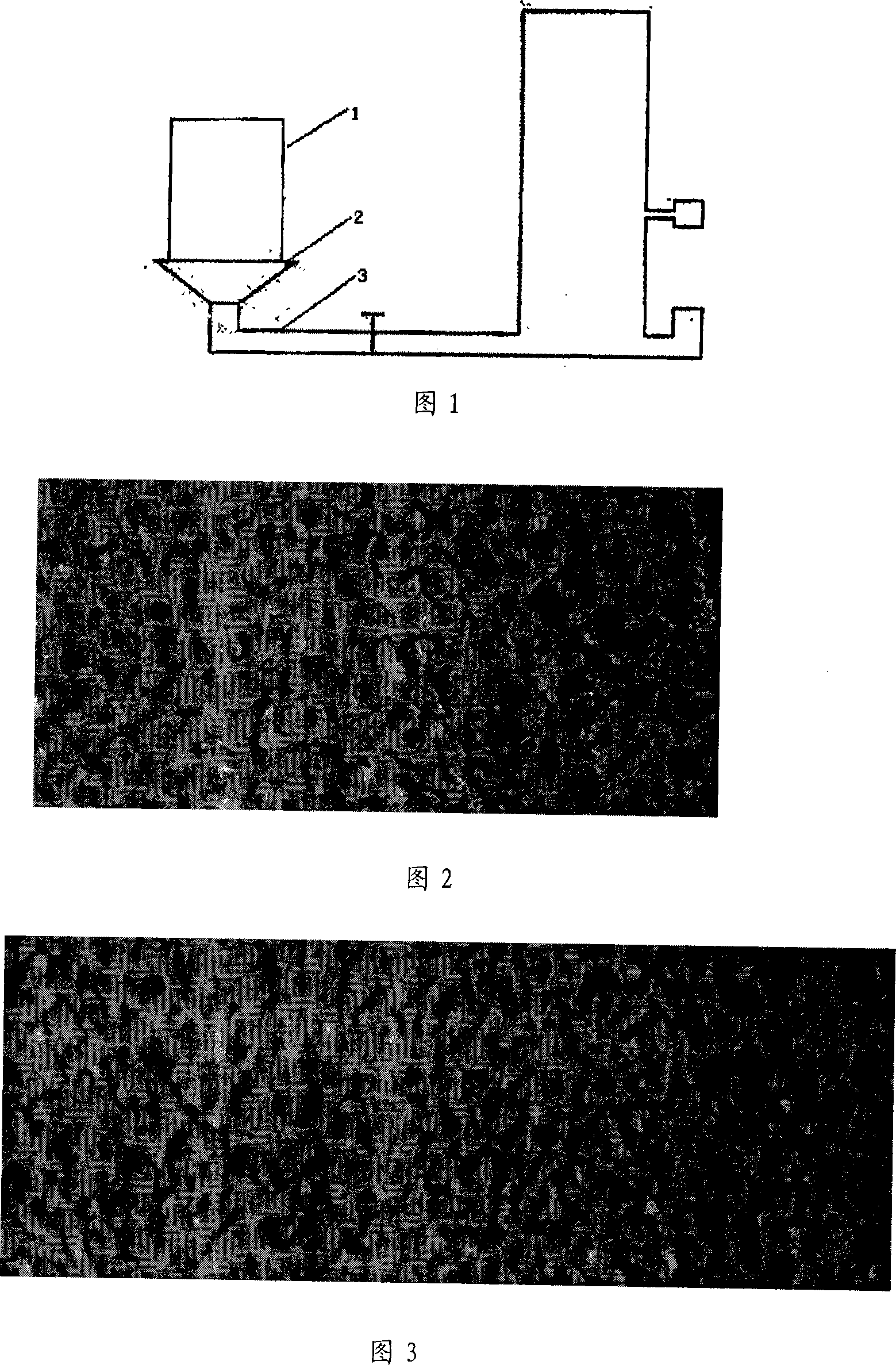

[0023] A preparation method for through-hole porous aluminum and aluminum alloy with pore structure modulation, comprising the following steps:

[0024] In the first step, soluble chlorides or carbonates are used as filler particles, which are divided into groups according to the size of the particles; along the height direction of the mold 1, layered into the mold 1 according to the axial gradient distribution according to the size of the particles, at 500 Keep warm at ℃ for 30 minutes to make the temperature of the filler particles uniform;

[0025] The second step is to heat the aluminum alloy to melt, keep the temperature of the aluminum alloy melt at 700°C to 820°C, then place the mold 1 on the suction cup base 2 of the negative pressure device 3, the pressure is -2kPa, and melt the aluminum alloy The body is cast into the mold 1 to infiltrate the aluminum alloy melt into the filler particles;

[0026] In the third step, after the aluminum alloy is solidified and the alu...

Embodiment 2

[0028] A preparation method for through-hole porous aluminum and aluminum alloy with pore structure modulation, comprising the following steps:

[0029] In the first step, soluble chloride or carbonate is used as filler particles, which are divided into groups according to particle size; along the height direction of mold 1, they are loaded into mold 1 in layers according to the axial gradient distribution according to pore size, and the Keep it warm for 30 minutes to make the temperature of the filler particles uniform;

[0030] The second step is to heat the aluminum alloy until it melts, and keep the temperature of the aluminum alloy melt at 700°C to 820°C, then place the mold 1 on the suction cup base 2 of the negative pressure device 3 at a pressure of -20kPa, and melt the aluminum alloy. The body is cast into the mold 1 to infiltrate the aluminum alloy melt into the filler particles;

[0031] In the third step, after the aluminum alloy is solidified and the aluminum all...

Embodiment 3

[0033] A preparation method for through-hole porous aluminum and aluminum alloy with pore structure modulation, comprising the following steps:

[0034] In the first step, soluble chlorides or carbonates are used as filler particles, which are divided into groups according to the size of the particles; along the height direction of the mold 1, they are loaded into the mold 1 in layers according to the axial gradient distribution according to the pore size, and the temperature is 660 ° C. Keep it warm for 30 minutes to make the temperature of the filler particles uniform;

[0035] The second step is to heat the aluminum alloy until it melts, and keep the temperature of the aluminum alloy melt at 700°C to 820°C, then place the mold 1 on the suction cup base 2 of the negative pressure device 3 at a pressure of -40kPa, and melt the aluminum alloy The body is cast into the mold 1 to infiltrate the aluminum alloy melt into the filler particles;

[0036] In the third step, after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com