Article storing device

A storage device and article technology, which is applied to storage devices, transportation and packaging, etc., can solve the problems of increasing the time spent in transporting substrates, and the inability to configure manufacturing processes nearby.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, preferred embodiments of the present invention will be described.

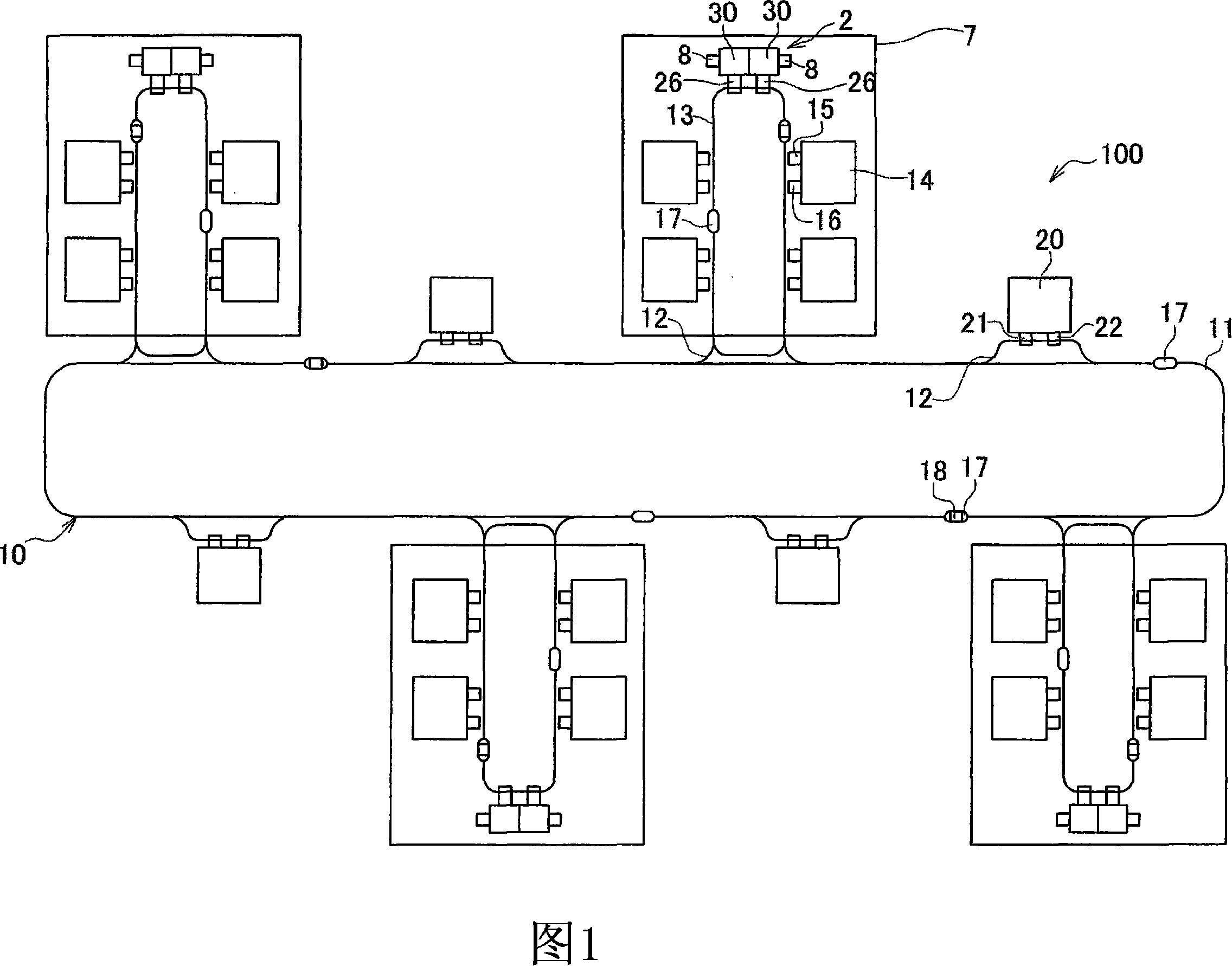

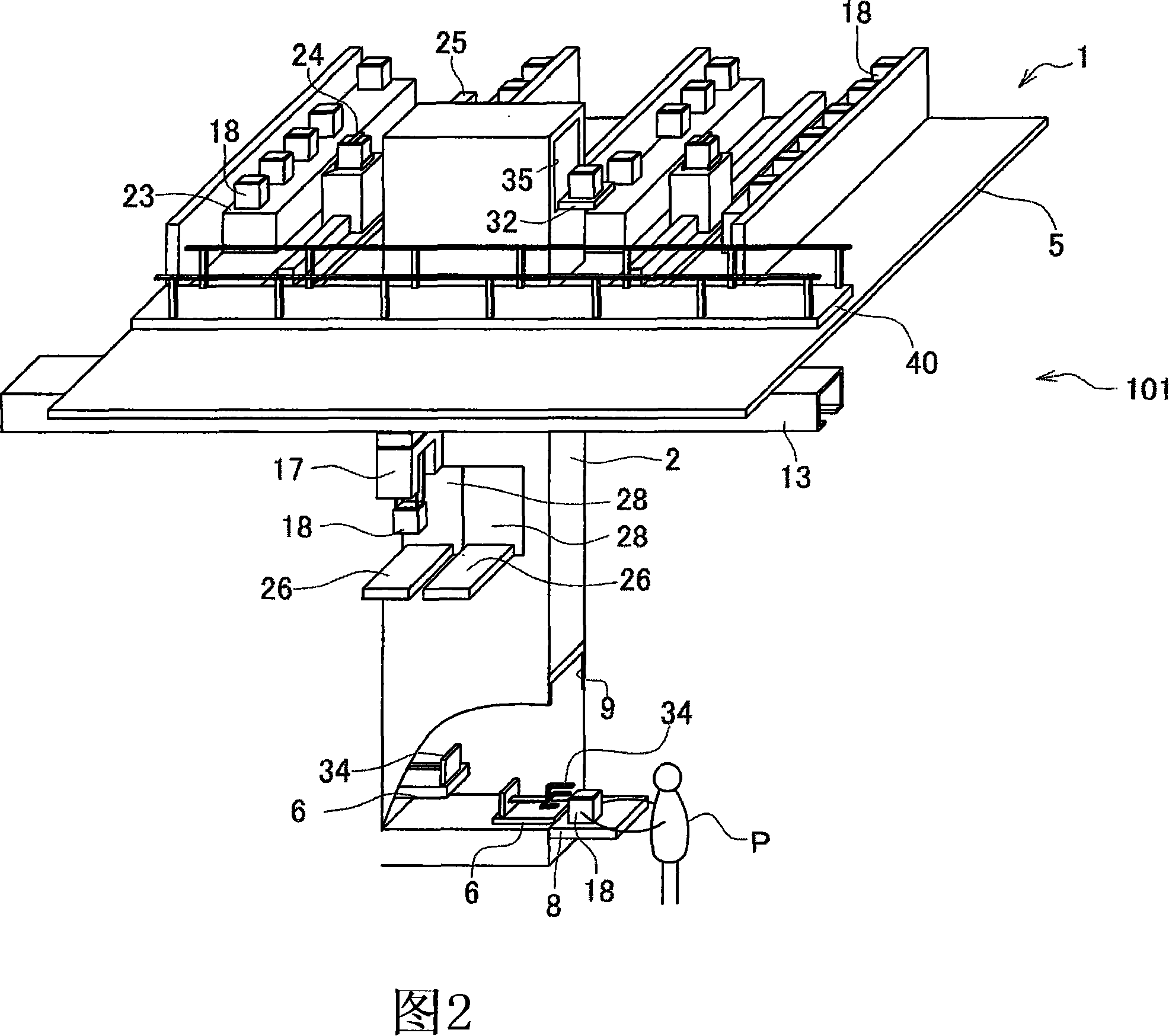

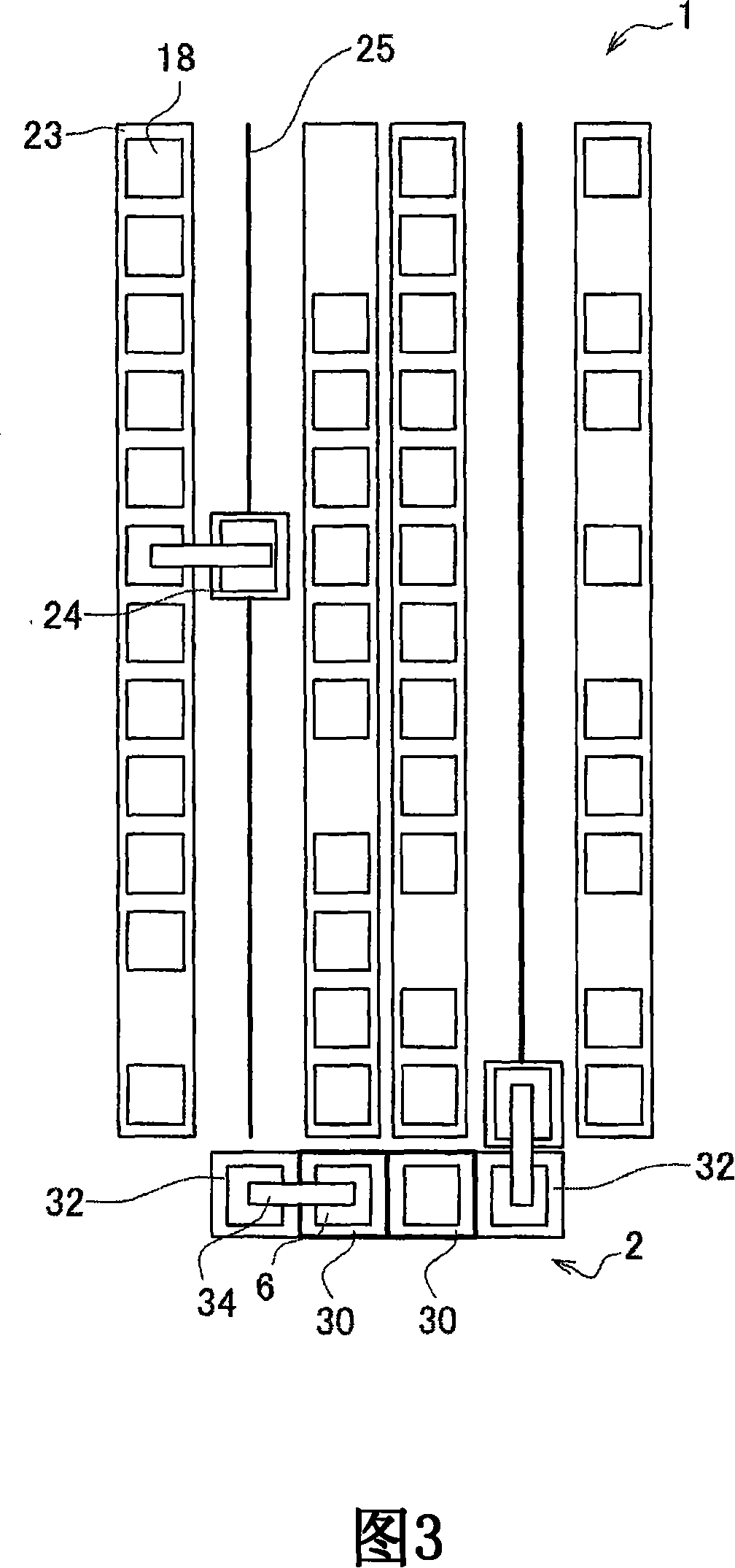

[0034] Fig. 1 is a schematic configuration diagram of a portion excluding the inside of the ceiling of a conveyance system according to an embodiment of the present invention. FIG. 2 is a partial perspective view of a lifting device 2 in FIG. 1 and the corresponding lifting device 2 in the ceiling. Fig. 3 is a top view of the inner part of the ceiling in Fig. 2 . The transport system 10 is set in the clean room of the semiconductor manufacturing factory, as shown in Figures 1 to 3, it has four inter-fields 7, four storages 20, transport tracks 10, OHT (Overhead Hoist Transport) transport trolleys 17 And a storage device (item storage device) 101.

[0035] Four spacers 7 are arranged in double rows in the vertical direction of FIG. 1 and in the left-right direction of FIG. 1 . Four semiconductor manufacturing apparatuses 14 are provided in each inter-field 7, and each process of semiconductor ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com