Horizontal disc plastic injection forming machine

An injection molding machine and disc technology, which is applied in the field of disc type plastic injection molding machines, can solve the problems of long time consumption, low production efficiency, long stroke of the clamping cylinder piston, etc., and achieves shortened stroke time, simple structure, and improved production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

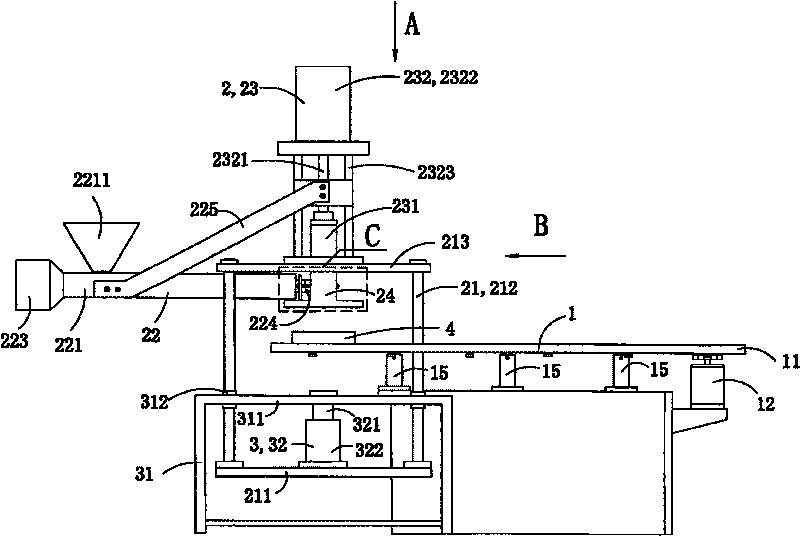

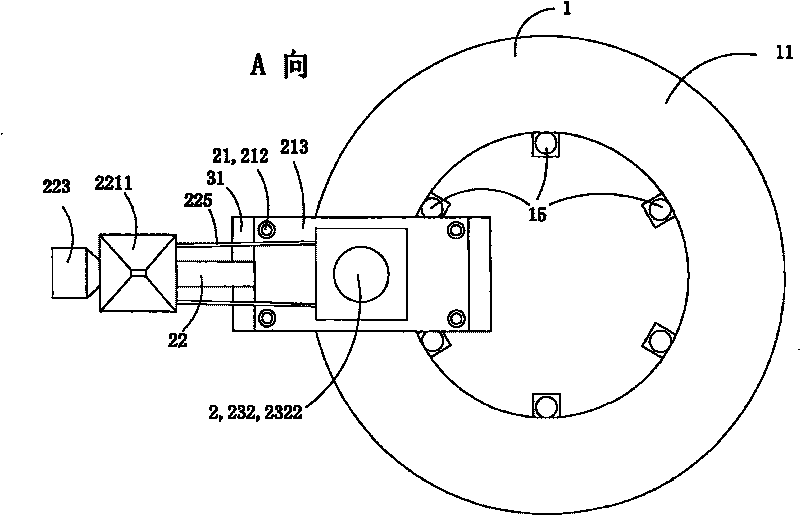

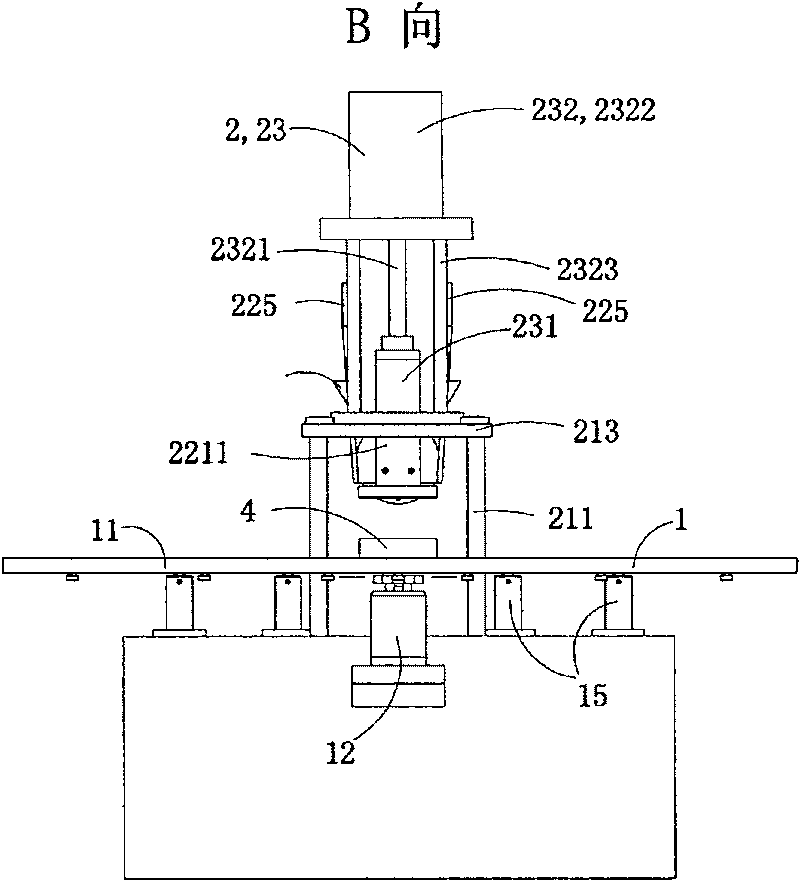

[0048] Figure 1 to Figure 8 A first embodiment of the invention is shown. in, figure 1 It is the first structure schematic diagram of the present invention; figure 2 yes figure 1 A-direction view; image 3 yes figure 1 B direction view; Figure 4 yes figure 1 Partial enlarged schematic diagram at C; Figure 5 yes Figure 4 cutaway diagram of Figure 6 yes figure 1 Schematic diagram of the cross-sectional structure of the middle injection nozzle arranged in the injection port of the injection head; Figure 7 yes Figure 5 Schematic diagram of the cross-sectional structure of the middle injection port; Figure 8 yes Figure 5 Schematic diagram of the cross-sectional structure of the middle injection nozzle.

[0049] See Figure 1 to Figure 3 , this embodiment is a single-color horizontal disc plastic injection molding machine, including a turntable device 1, an injection device 2 and a mold clamping device 3; Feet 15 and the driving device 12 that drives the ro...

Embodiment 2

[0064] Figure 9 to Figure 14 A second embodiment of the invention is shown, Figure 9 is a schematic diagram of the second structure of the present invention; Figure 10 yes Figure 9 Partial cross-sectional view at D; Figure 11 yes Figure 9 Schematic diagram of the cross-sectional structure of the Zhongguan feed nozzle set at the feed port of the injection head; Figure 12 yes Figure 11 Sectional view of the middle feed port; Figure 13 yes Figure 12 View from E direction; Figure 14 yes Figure 11 Schematic diagram of the structure of the Zhongguan material nozzle; Figure 15 yes Figure 14 F direction view.

[0065] This implementation is basically the same as Embodiment 1, the difference is:

[0066] See Figure 9 The turntable device 1 also has a pressure-bearing tray 13 for supporting the disc 11 when the injection head is pressed against the mold and is fixedly arranged relative to the clamping frame 31. In non-injection molding, that is, when the inje...

Embodiment 3

[0071] Figure 16 It is a schematic cross-sectional structural diagram of the connection between the pre-molding mechanism and the injection head through the injection connector in the third structure of the present invention, showing the third embodiment of the present invention.

[0072] This embodiment is basically the same as Embodiment 1, the difference is that: the shape of the discharge connection part 2242 of the feeding coupling 224 is a conical tenon with a protruding conical surface, and the feed of the injection head The shape of the connecting portion 244 is a frustum-shaped groove with an inner concave tapered surface matching the shape of the discharge connecting portion 2242 of the feeding coupling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com