Automatic sewing machine

A sewing machine and automatic technology, applied in the direction of program-controlled sewing machines, sewing machine components, sewing machine needle holders, etc., can solve the problems of imbalance, torque load increase, pulse motor can not follow the pulse output, etc., to achieve the suppression of imbalance and sewing quality The effect of improving and preventing needle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

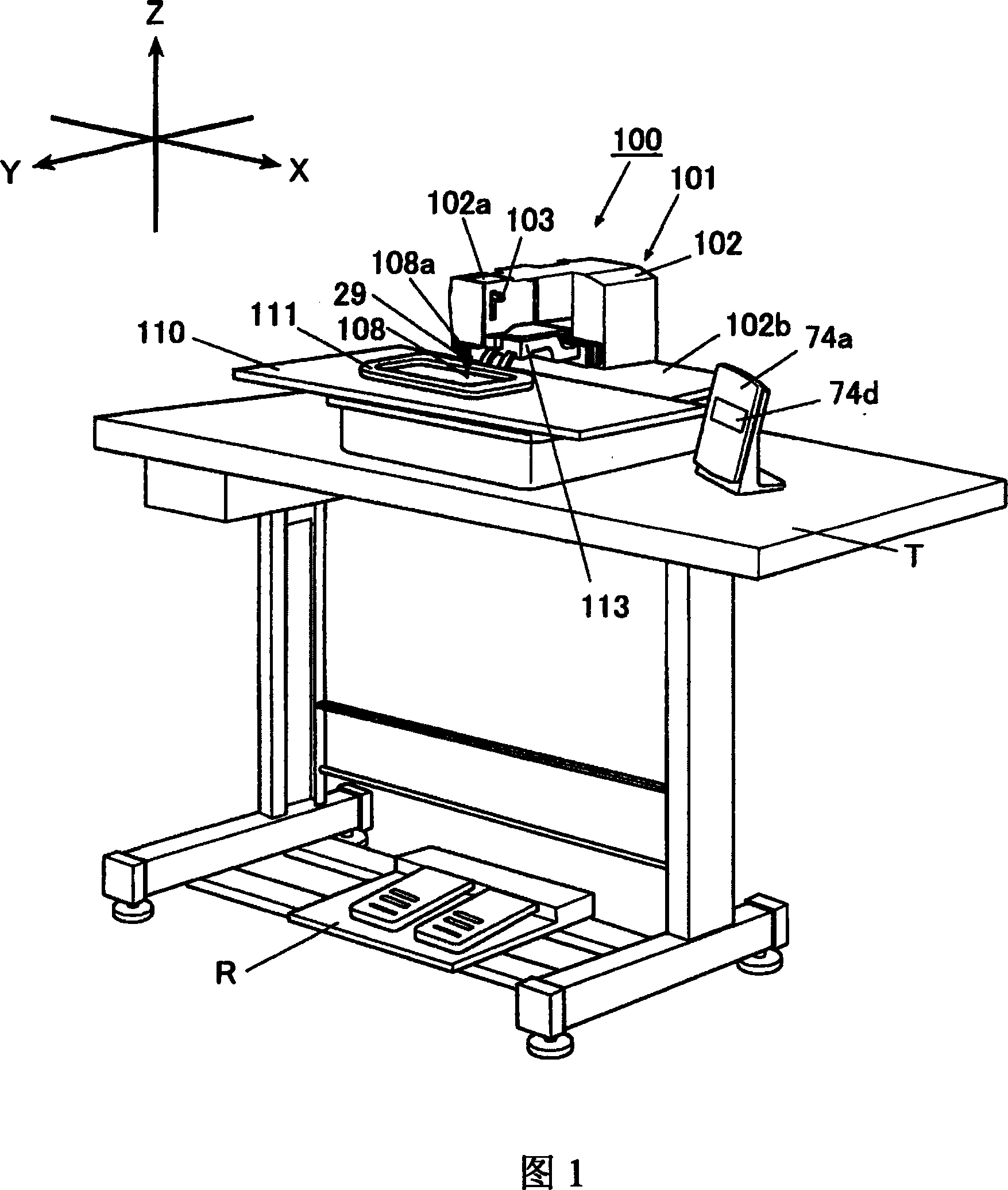

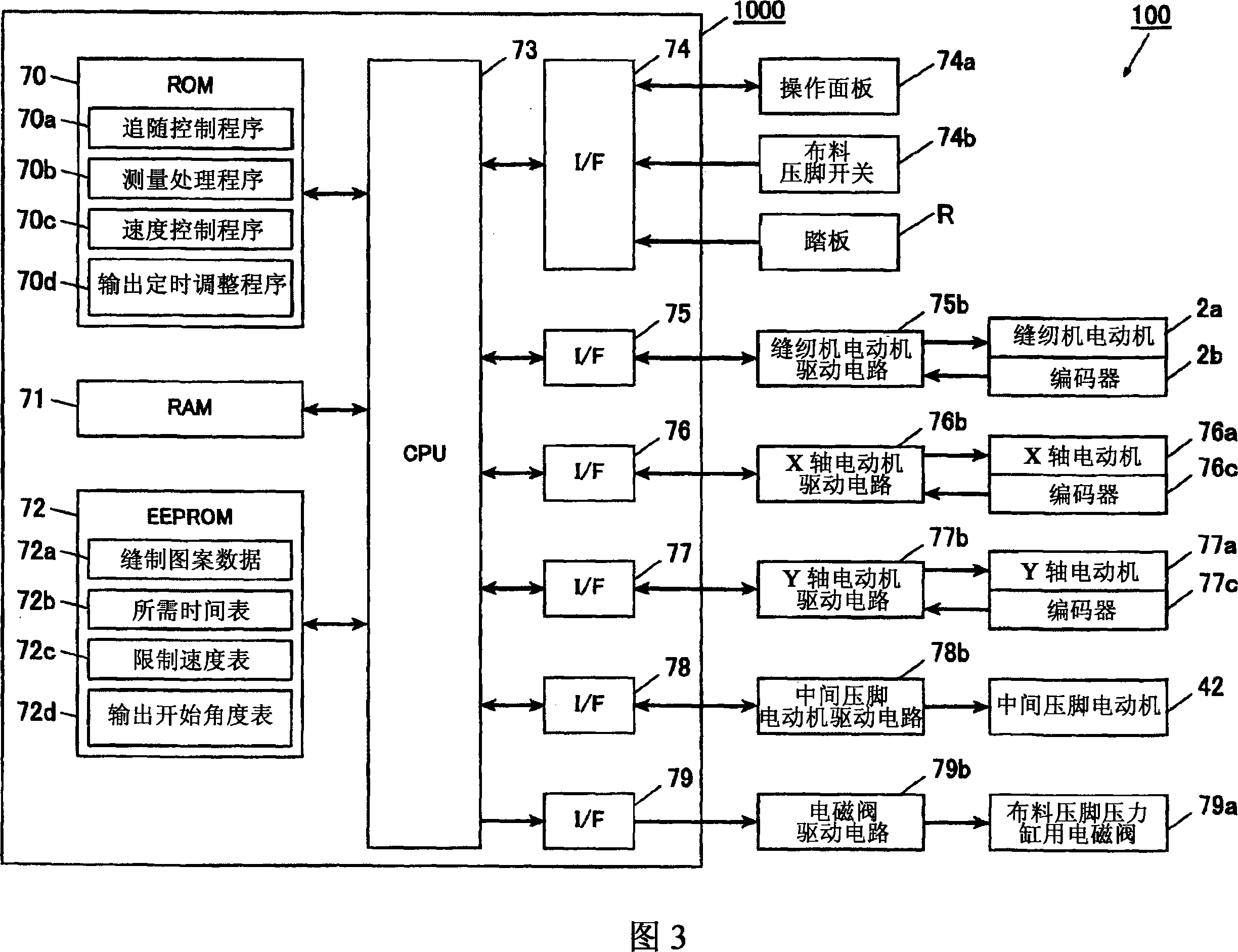

[0045] (The overall structure of the electronic cycle sewing machine)

[0046] Embodiments of the present invention will be described based on FIGS. 1 to 10 .

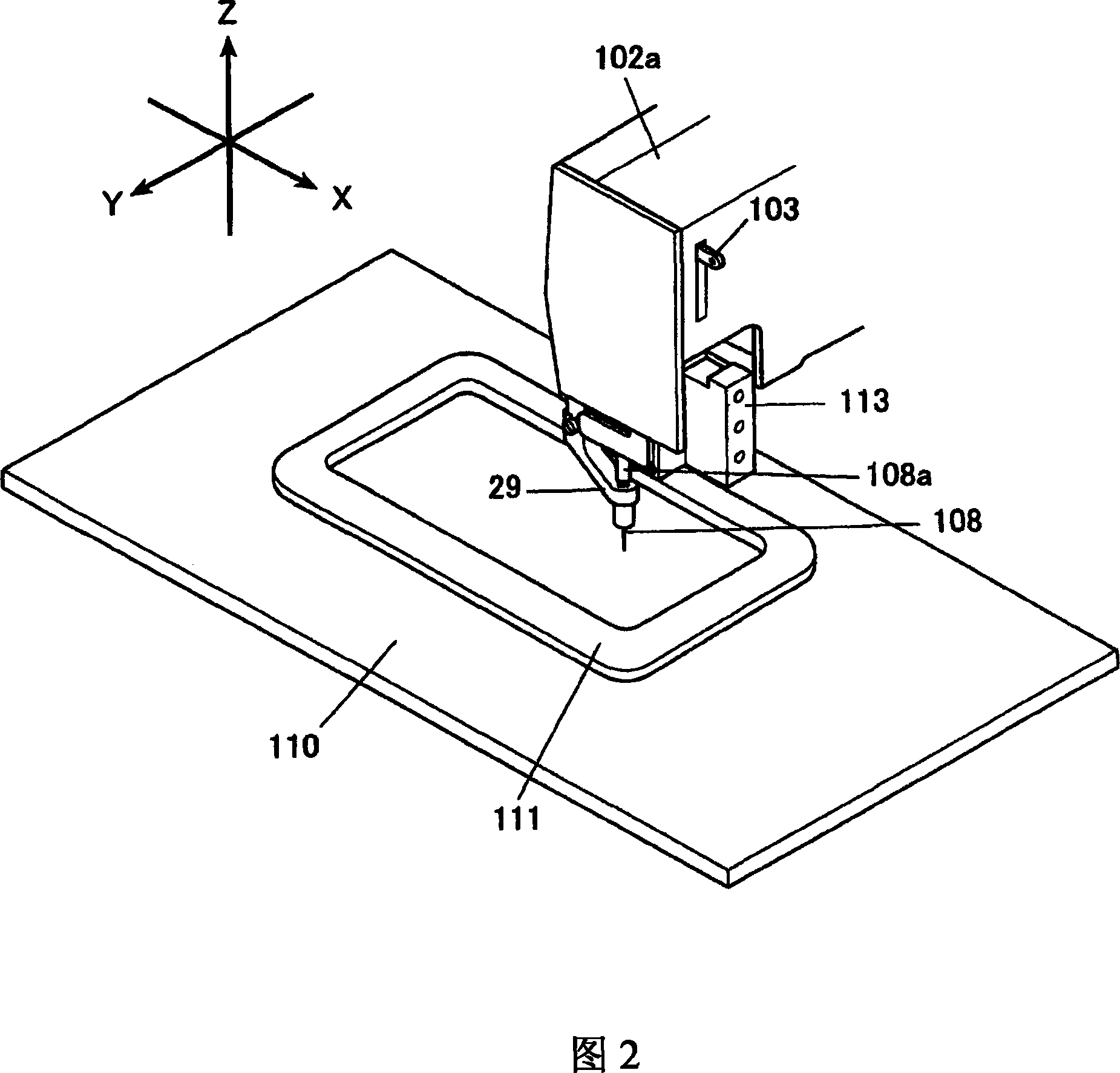

[0047] In this embodiment, an electronic cycle sewing machine as an automatic sewing machine will be described as an example. The electronic cycle sewing machine is a sewing machine as follows: it has a holding frame as a cloth holding member, and the holding frame holds a sewing object, that is, a cloth, and moves relatively with respect to the sewing needle through the holding frame. Stitches based on predetermined sewing data (sewing patterns) are formed on the material on the holding frame.

[0048] Here, the direction in which the sewing needle 108 described later moves up and down is defined as the Z-axis direction (up-and-down direction), and a direction perpendicular to it is defined as the X-axis direction (left-right direction), and the Z-axis direction and the Y-axis direction are defined as Direction The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com