Heat storage type vertical metal magnesium reducing furnace

A metal magnesium reduction furnace technology, applied in the field of regenerative vertical metal magnesium reduction furnace, can solve the problems of high exhaust gas temperature, easy dust accumulation in the reduction tank, insufficient fuel combustion, etc., to reduce the exhaust gas temperature, burn Unique method, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

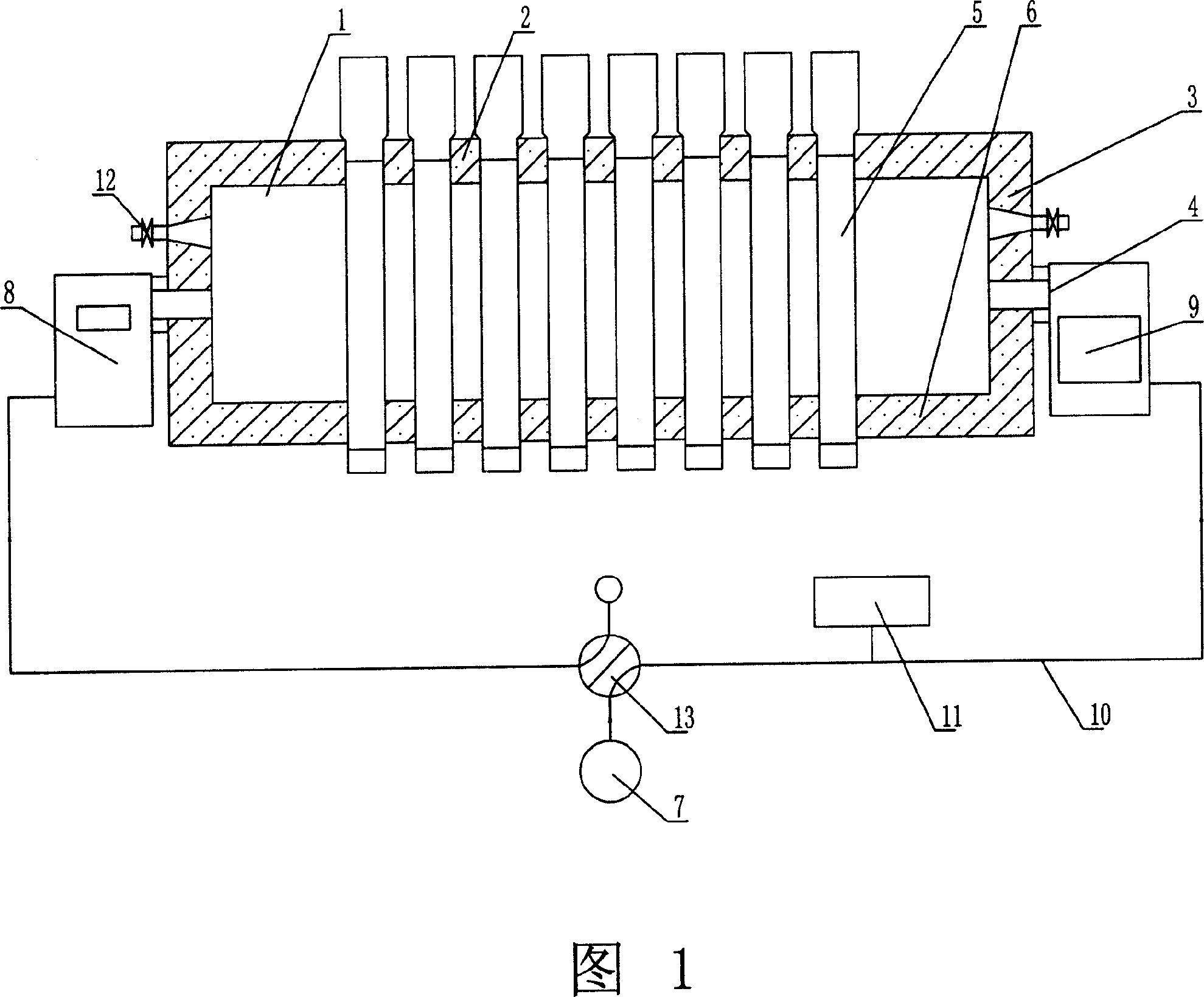

[0024] A regenerative vertical metal magnesium reduction furnace is composed of a hearth 1, a furnace roof 2, a furnace wall 3, a burner 4, a reduction tank 5, a furnace bottom regenerator 6 and a fan 7, as shown in Figure 1: There are several pairs of double regenerative burners 4 correspondingly arranged at the bottom of both ends in the furnace width direction, forming a regenerator I8 and a regenerator II9 at the bottom of the furnace at both ends, and installing two reversing valves 13 at each end, and reversing The valve 13 is connected to the regenerator I8, the regenerator II9 and the fan 7 through the pipeline 10 outside the furnace and the reversing control system 11. The reduction tank 5 in the furnace 1 is arranged in a vertical manner, with the upper part feeding and the lower part discharging slag. The reduction tanks 5 in the furnace 1 are divided into four rows on average, each row of reduction tanks 5 is spaced at a certain distance, and two pairs of the air an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com