A percussion drill possessing magnetometric percussion arrangement

An impact mechanism and impact drill technology, applied in the field of impact drills, can solve the problems of loss, large vibration and noise, heat generation, etc., achieve long service life, reduce vibration and noise, and save lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

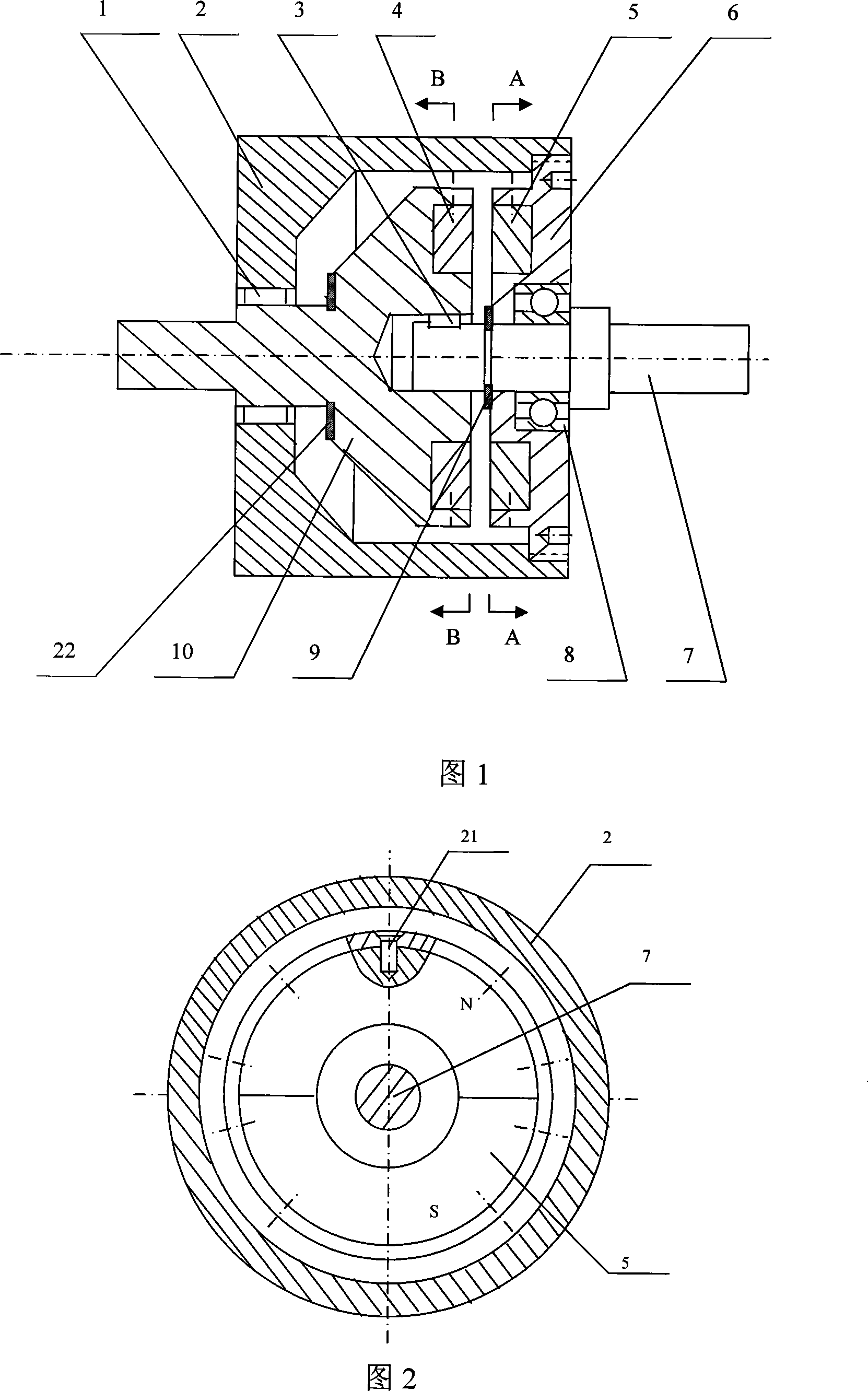

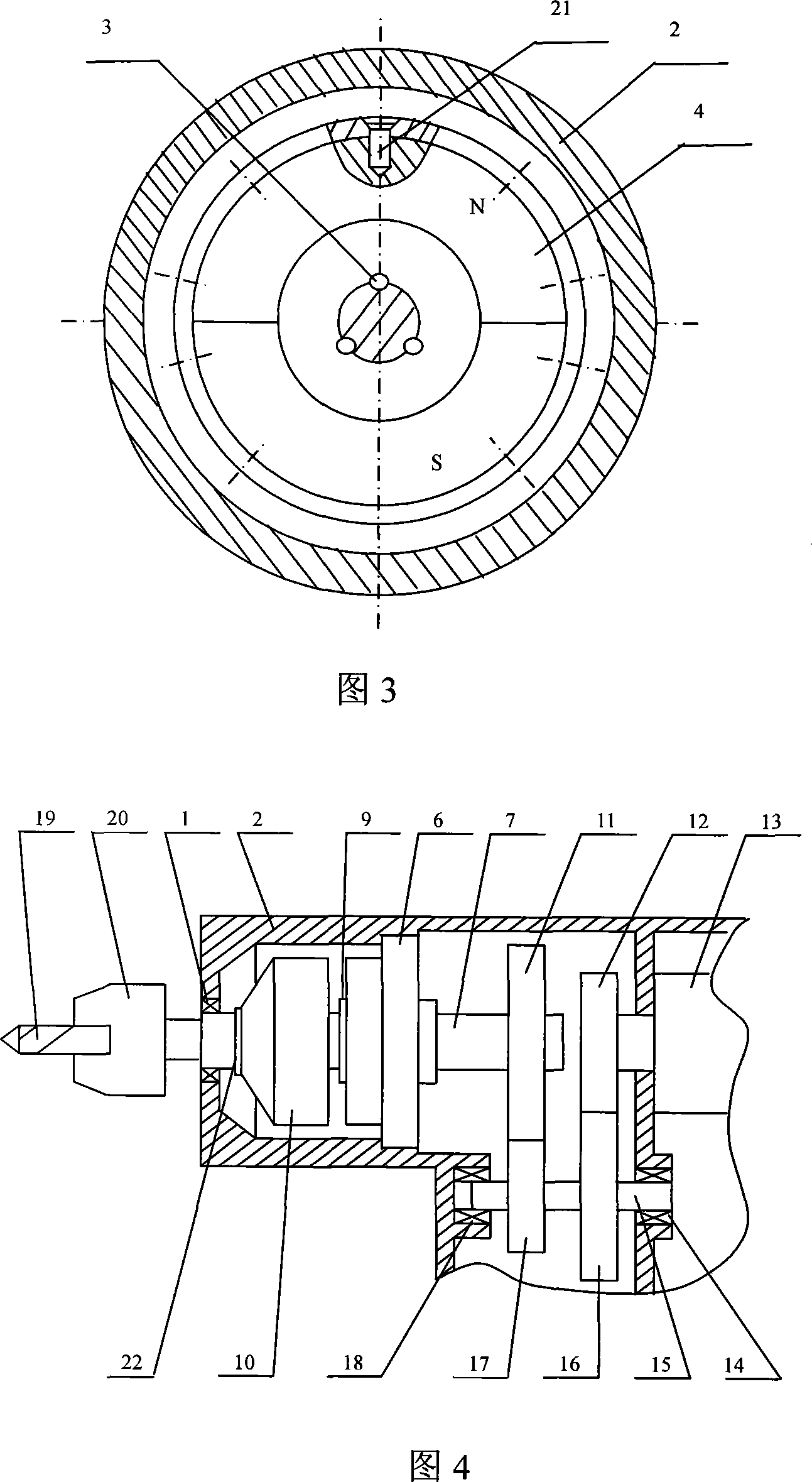

[0016] As shown in Figures 1 and 4, the present invention includes a housing 2, a motion transmission mechanism consisting of a motor 13, a drive gear 11, a motor gear 12, an intermediate gear 16 and an intermediate pinion 17, an impact mechanism and a drill chuck 20. The impact mechanism is a magnetic impact mechanism, and the small end shaft of the conical drive disc 10 is equipped with a rubber washer 22 to reduce the impact on the housing when the drive disc 10 moves axially. The small end shaft is supported by the first bearing 1 The front end of the housing 2 extends out of the housing 2, and the drill chuck 20 is installed. The large end surface of the conical drive disc 10 has an annular groove, and the first annular permanent magnet 4 is housed in the groove, and the support 6 is installed on the Inside the casing 2, the support 6 is threadedly connected with the casing 2, the drive shaft 7 is supported in the support 6 through the second bearing 8, and rotates relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com