Error correcting method for pressure sensor

A pressure sensor and error correction technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of cumbersome adjustment process, fixed adjustment temperature area, low production efficiency, etc., and achieve a simple and efficient correction method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

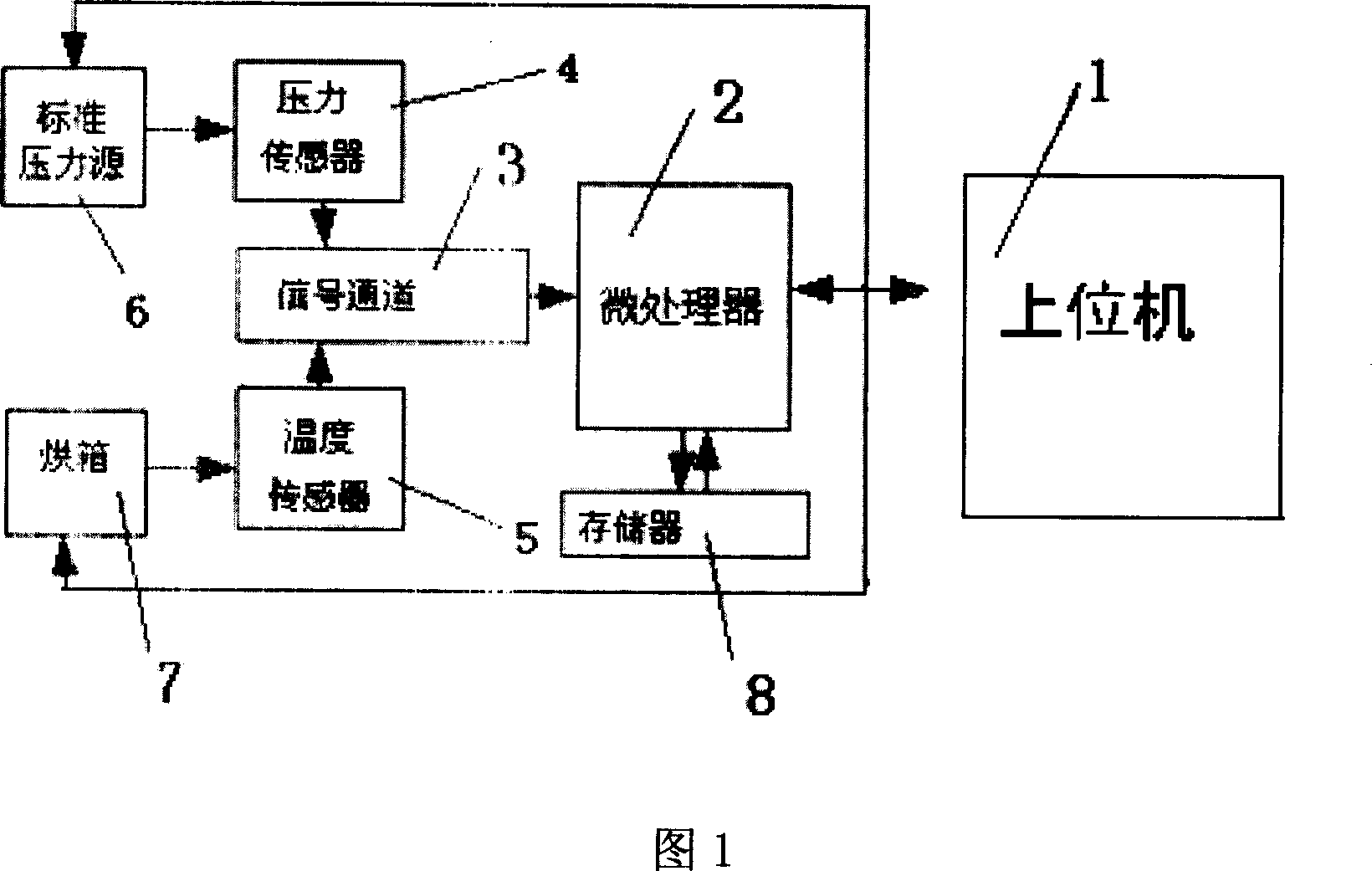

Method used

Image

Examples

example 1

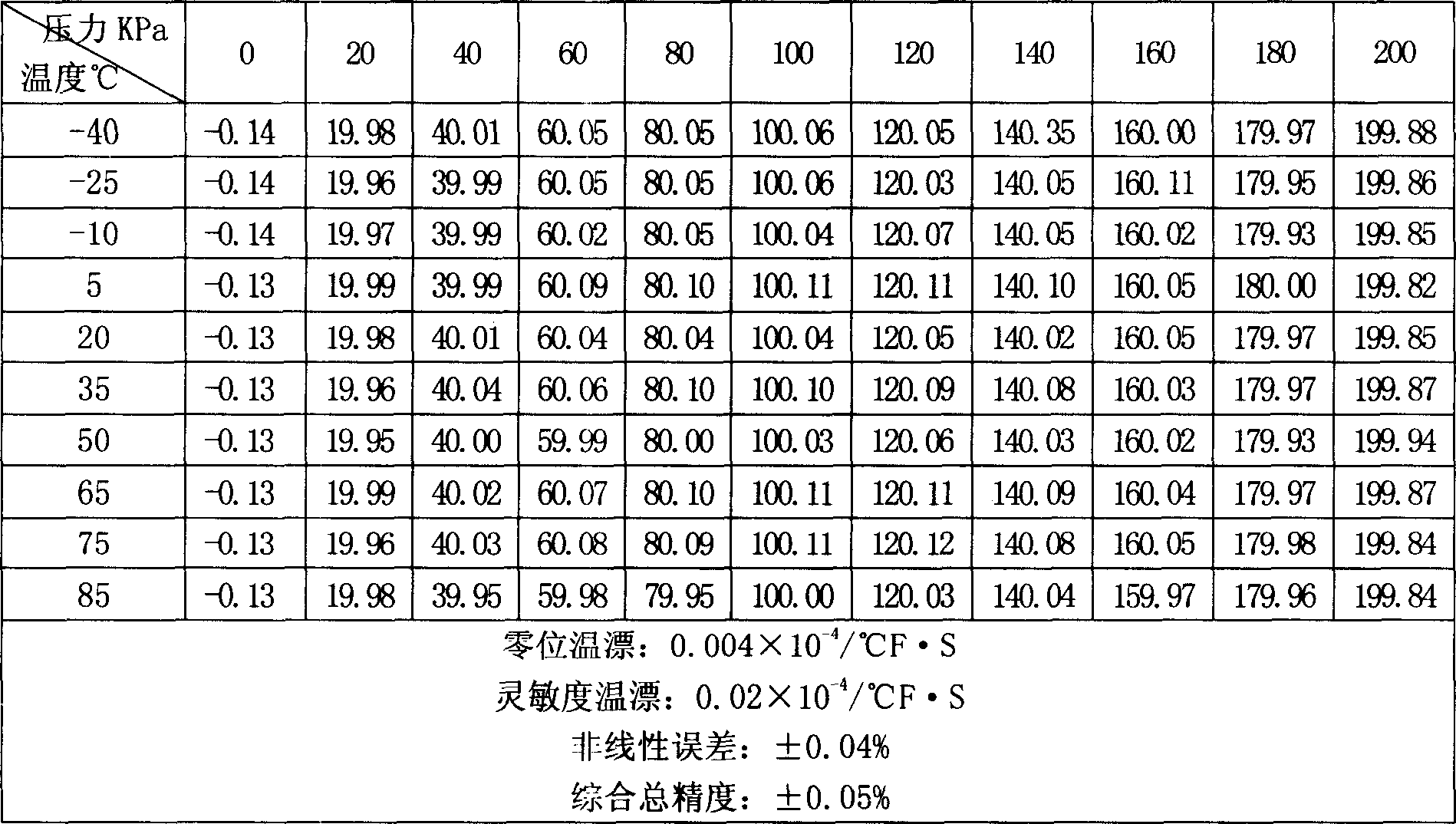

[0043] Example 1: The sensor raw sampling data matrix is as follows:

[0044] According to the test characteristics of the sensor, the compensation temperature zone of the sensor is decomposed into a sub-temperature zone every 15°C, a total of 9 sub-temperature zones.

[0045] (2) Calculate and correct the pressure sensor error compensation coefficient in the temperature zone

[0046] 1. According to the decomposed sensor output data of each sub-correction temperature zone, use the MATLAB self-built fitting program, and use the quadratic item fitting method to calculate the correction coefficients of the sensor.

[0047] Example of coefficient calculation process:

[0048] The output data of the sensor shown in Example 1 at -40°C is:

[0049] 3762

[0050] The expected output value is:

[0051] 0

[0052] Use the polyfit function that comes with MATLAB to calculate the two nonlinear correction parameters k3 and k4 (polyfit(X, Y, 2)).

[0053] Simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com