Antivibration pad for vehicle disc loading device

A technology of loading device and shock-absorbing pad, applied in the direction of record carrier turntable, spring, etc., can solve the problems of complex structure, many consumables, leakage of rubber damage and grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

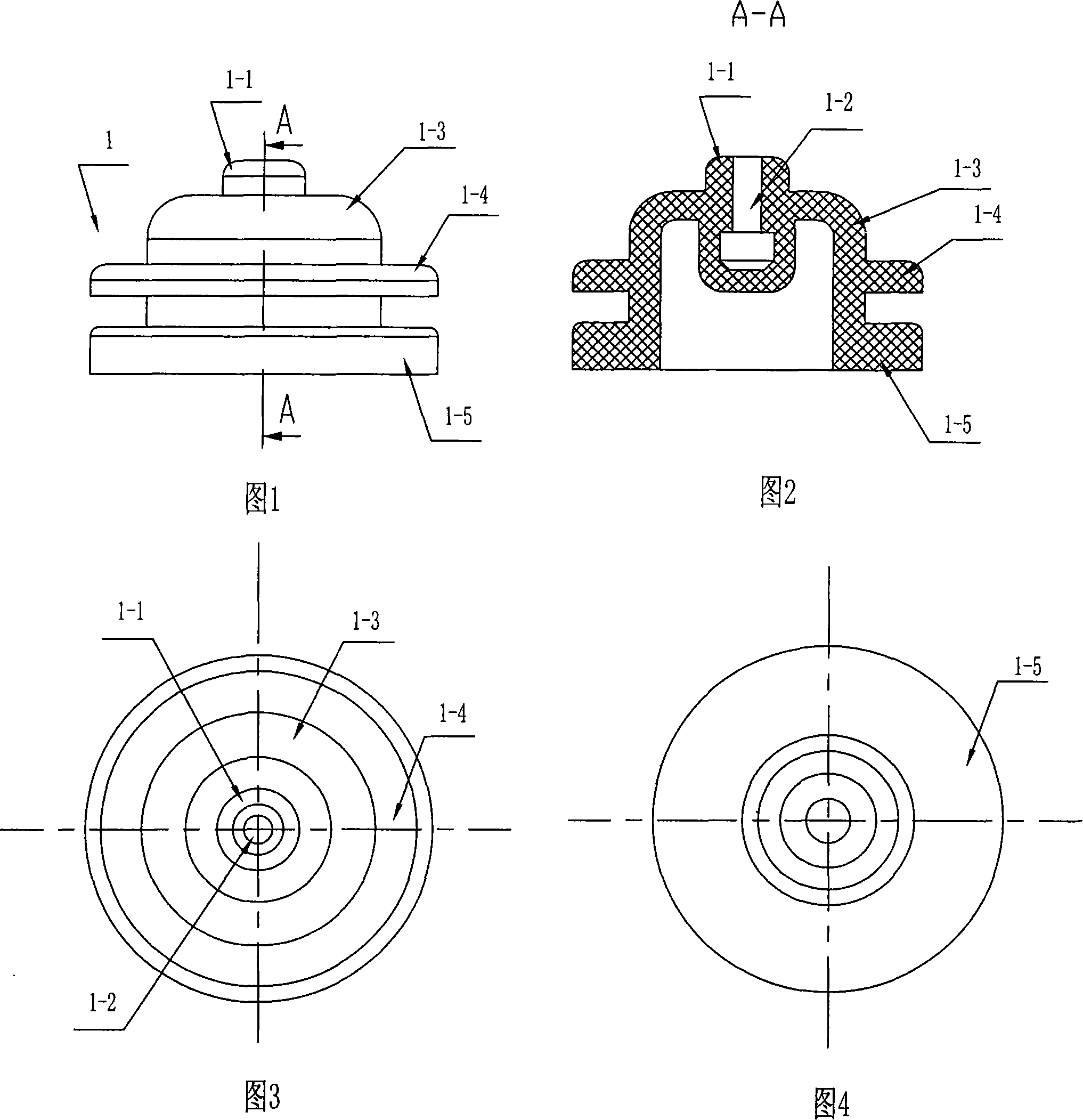

[0011] As shown in Figures 1 to 4, a shock absorber for a vehicle-mounted disc loading device is made of a high-damping rubber sleeve 1 with a cavity. The lower end of the rubber sleeve 1 is a cavity, and the upper end of the rubber sleeve 1 is a round platform 1- 1. There is a hollow shaft sheath 1-2 at the core of the circular table, the periphery of the rubber sleeve 1 has a deformation shoulder 1-3, the middle part of the outer circumference of the rubber sleeve 1 has an upper limit pad 1-4, and the lower end of the outer circumference of the rubber sleeve 1 has Lower limit pad 1-5.

[0012] As shown in Figures 1-4, the upper limit pad 1-4 is ring-shaped and surrounds the middle part of the outer wall of the rubber sleeve 1.

[0013] As shown in Figures 1-4, the lower limit pad 1-5 surrounds the lower end of the outer wall of the rubber s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com