Improved steam oil production method

A steam and Christmas tree technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of rock heating and high temperature, reduce clogging of downhole formations, reduce production, increase production and recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Take an oil well to carry out improved steam huff and puff oil recovery as an example for illustration.

[0027] A certain oil well has a heavy oil well with a reservoir depth of 1,000 meters, an original formation temperature of 50°C, and a reservoir thickness of 20 meters. The first round of steam huff and puff production was carried out.

[0028] A. Preparatory work: Run the steam injection string composed of high temperature resistant packer and heat-insulated tubing into the wellbore. After the packer is set, install the wellhead Christmas tree; use a steam boiler to prepare saturated steam, and connect the steam boiler Christmas tree tubing outlet;

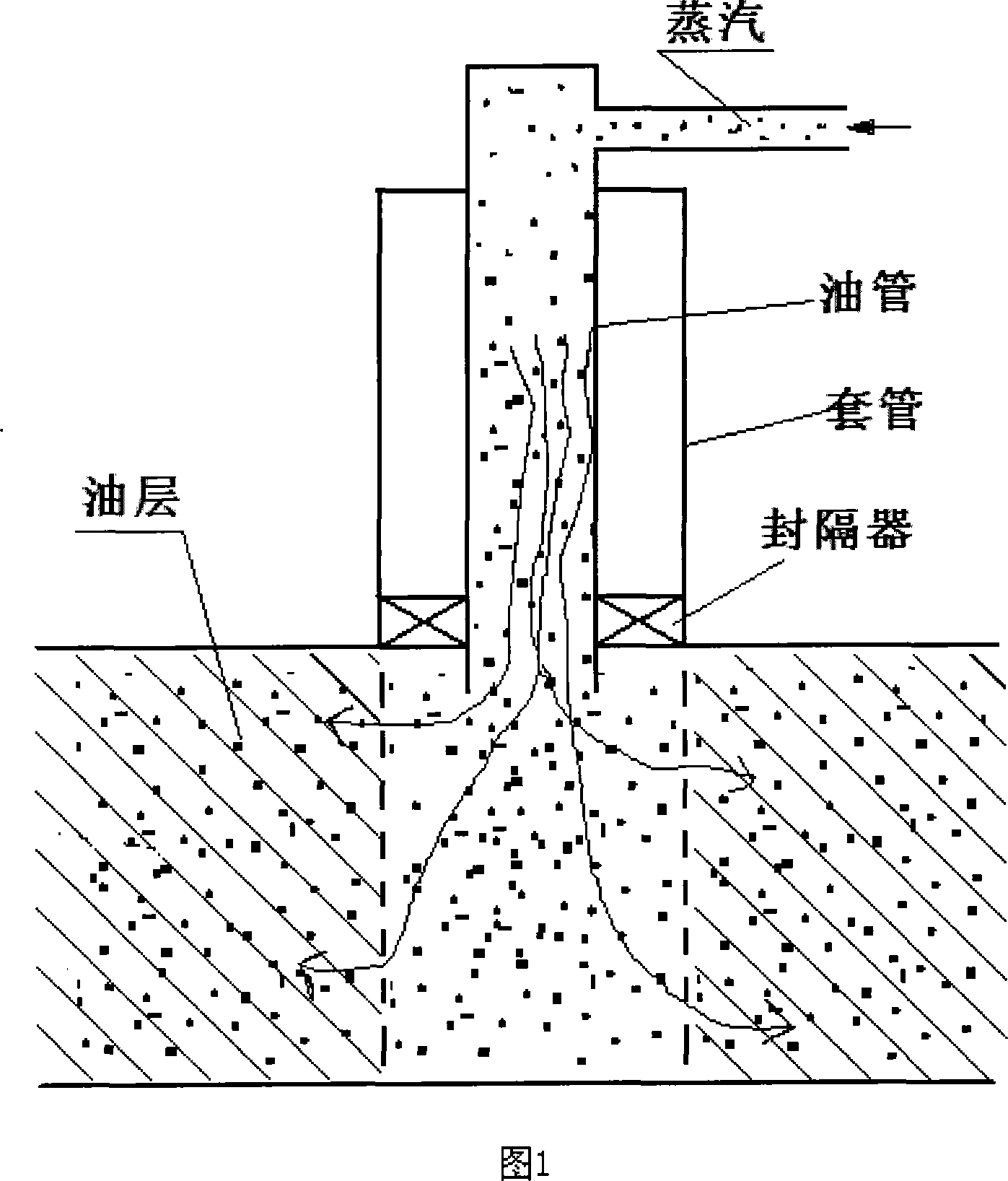

[0029] B. Injecting steam: refer to accompanying drawing 1. Inject saturated steam into the oil well, the amount of steam injected into the reservoir per meter thickness is 100 cubic meters, the dryness of the bottom hole is 50%, the injection rate is 400 tons / day, the maximum pressure of saturated stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com