Differential aeration sluice device

A differential type, sill-reeling technology, applied in the field of aerated sills, can solve problems such as aggravating water surface fluctuations, worsening downstream water flow patterns, increasing engineering volume, etc., reducing engineering costs, simple and easy structure, and extending protection length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The effectiveness of the invention is verified by using several different aeration types of a 1:30 scale model of a certain project.

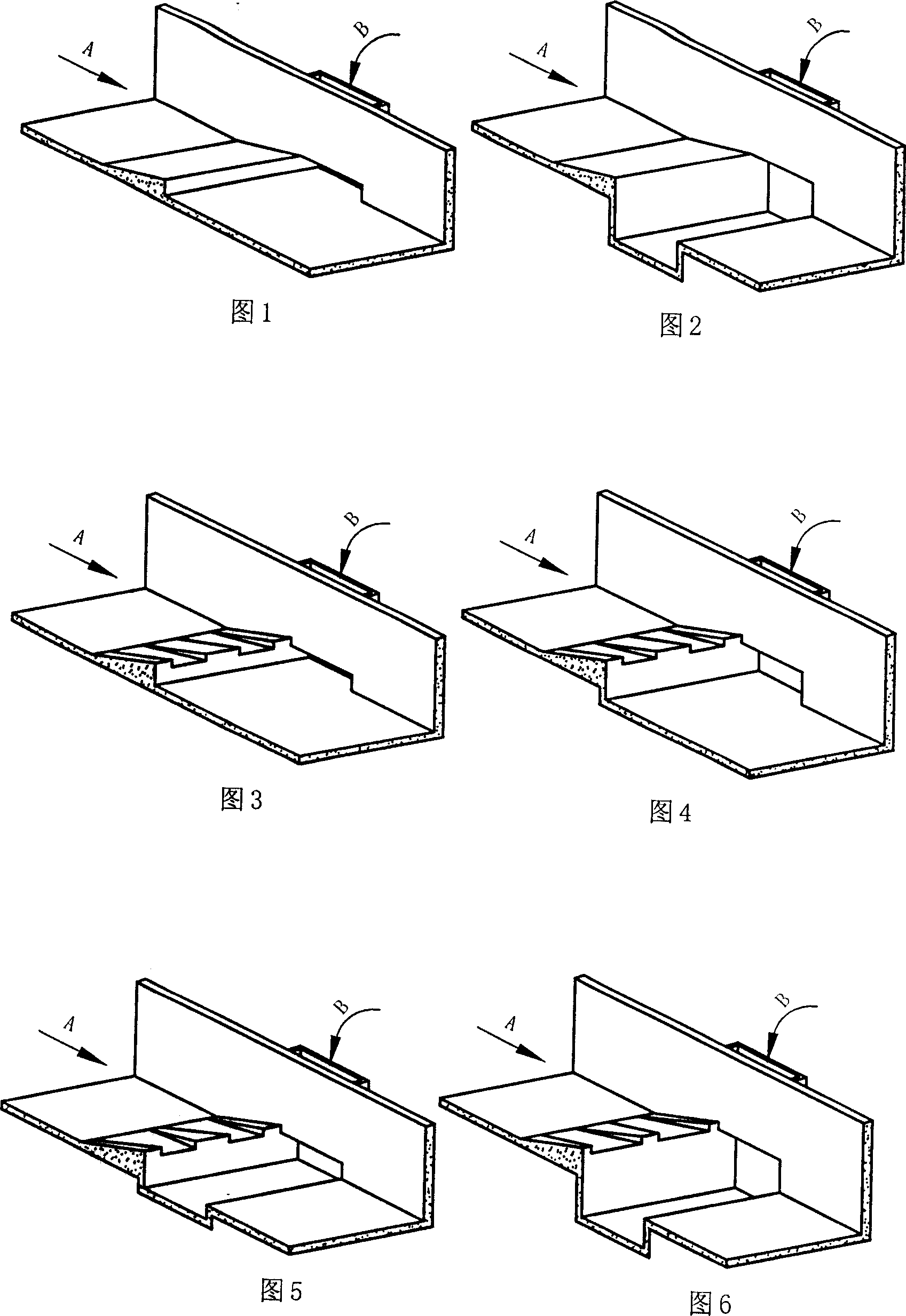

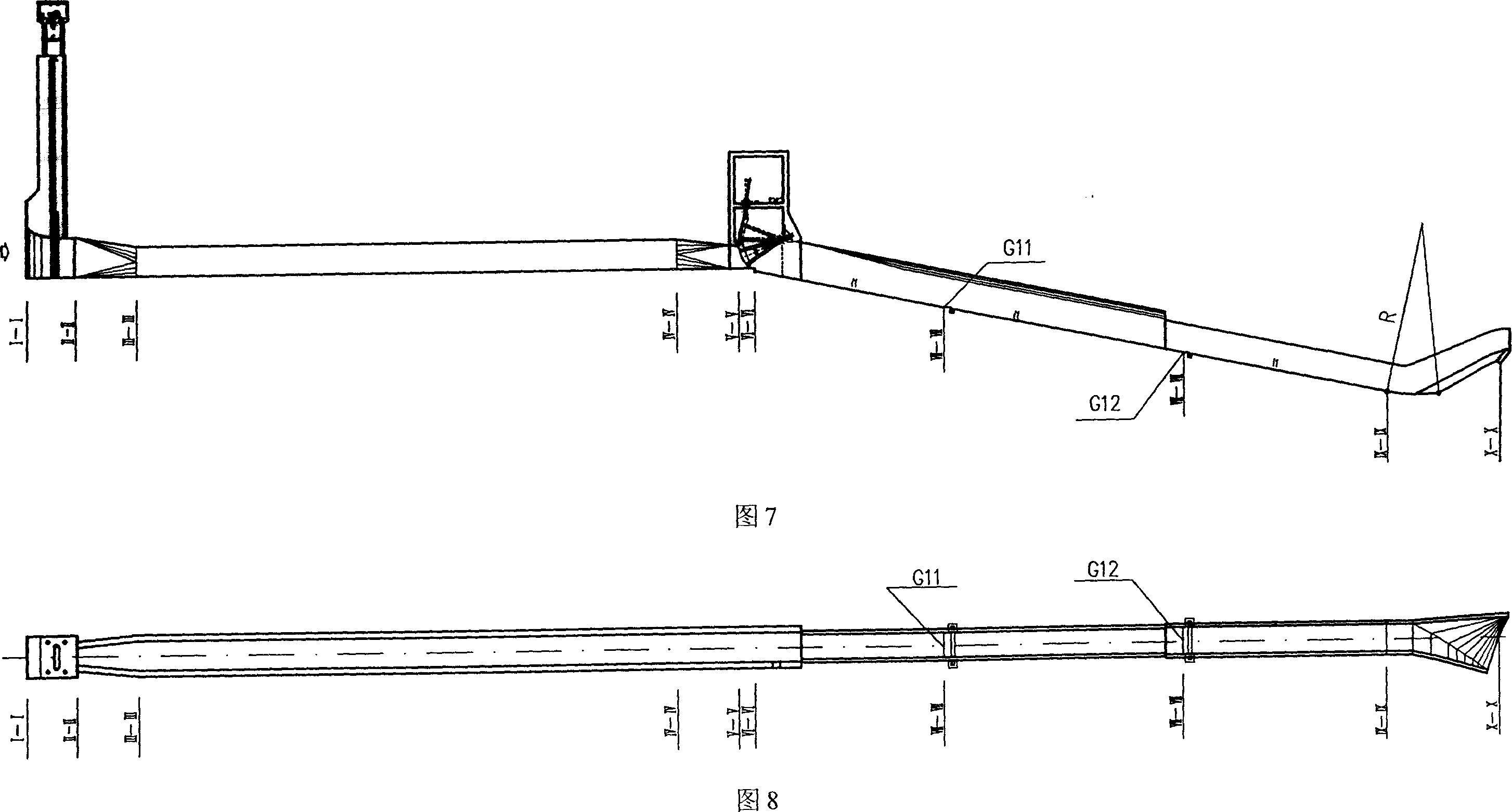

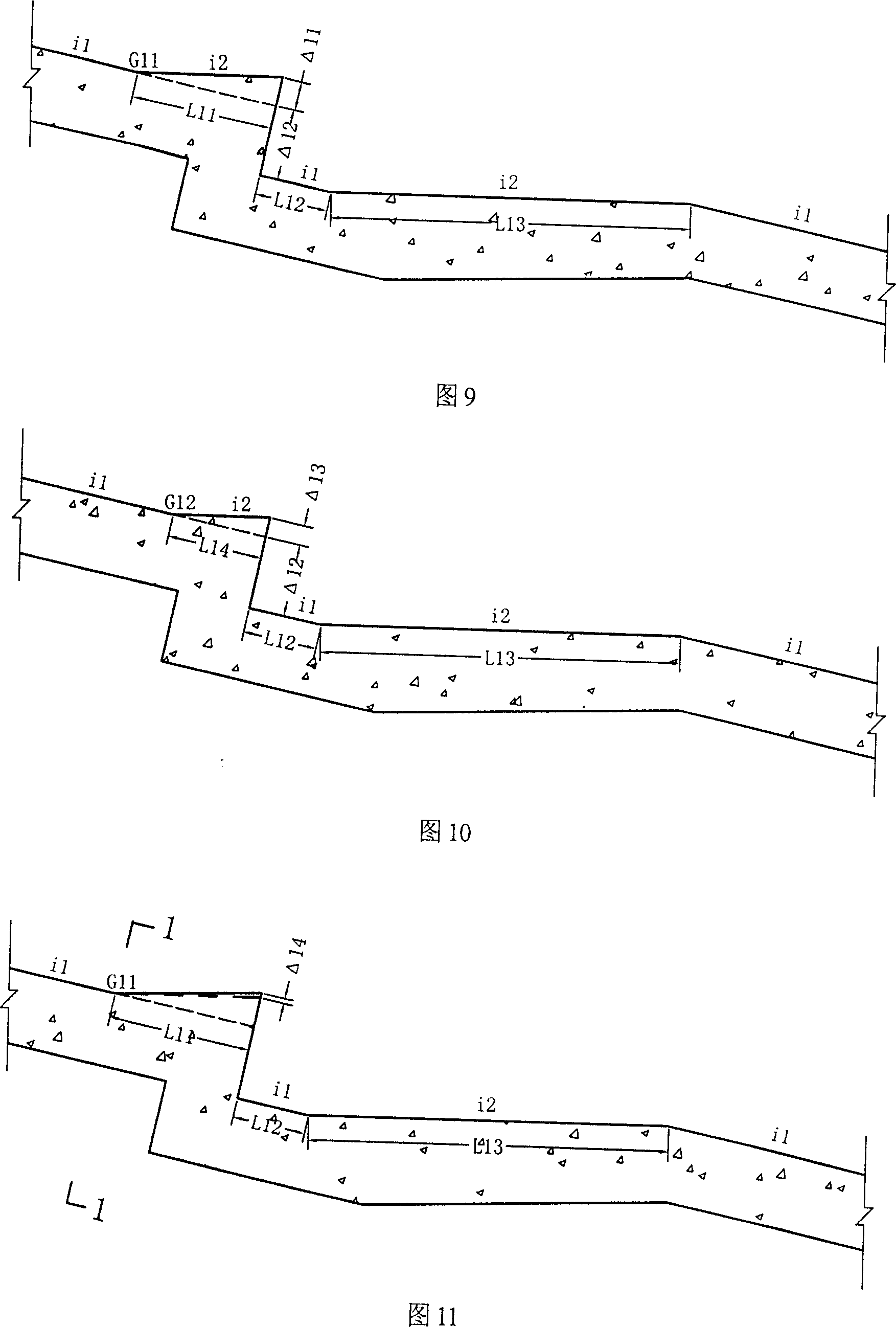

[0044] Under the same test conditions, only the shape of the ridge in the upstream and downstream aeration facilities is changed, and the prototype dimensions corresponding to each scheme are shown in Figure 7-14.

[0045] As shown in Figure 7 and Figure 8, the front section of the spillway tunnel is a 287.6m long horizontal section with pressure, and a drop sill (0+291.10m) is set behind the exit arc door, and the bottom slope (i1) of the spillway tunnel behind the drop sill is 0.2063, add two aeration facilities combining ridges and aeration tanks at stake number 0+374.63m (upstream ridge starting point G11) and 0+472.02m (downstream ridge starting point G12). At the outlet section of the spillway, from the pile number 0+555.88m, the bottom slope becomes arc-shaped (arc radius R=70m), and the rear part is a twisted nose sill outflow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com