Storage cage

A storage cage and base technology, applied in the field of storage cages, can solve the problems of more stringent process requirements, collapse, and inability to stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Through the applicant's detailed description below, it will be more helpful to understand the concept of the present invention, and make the advantages and positive effects of the present invention clearer. However, the description of the embodiments does not constitute a limitation of the present invention. A slight change in form or an equivalent substitution or a literal modification should be considered as belonging to the scope of the technical solutions disclosed in the present invention.

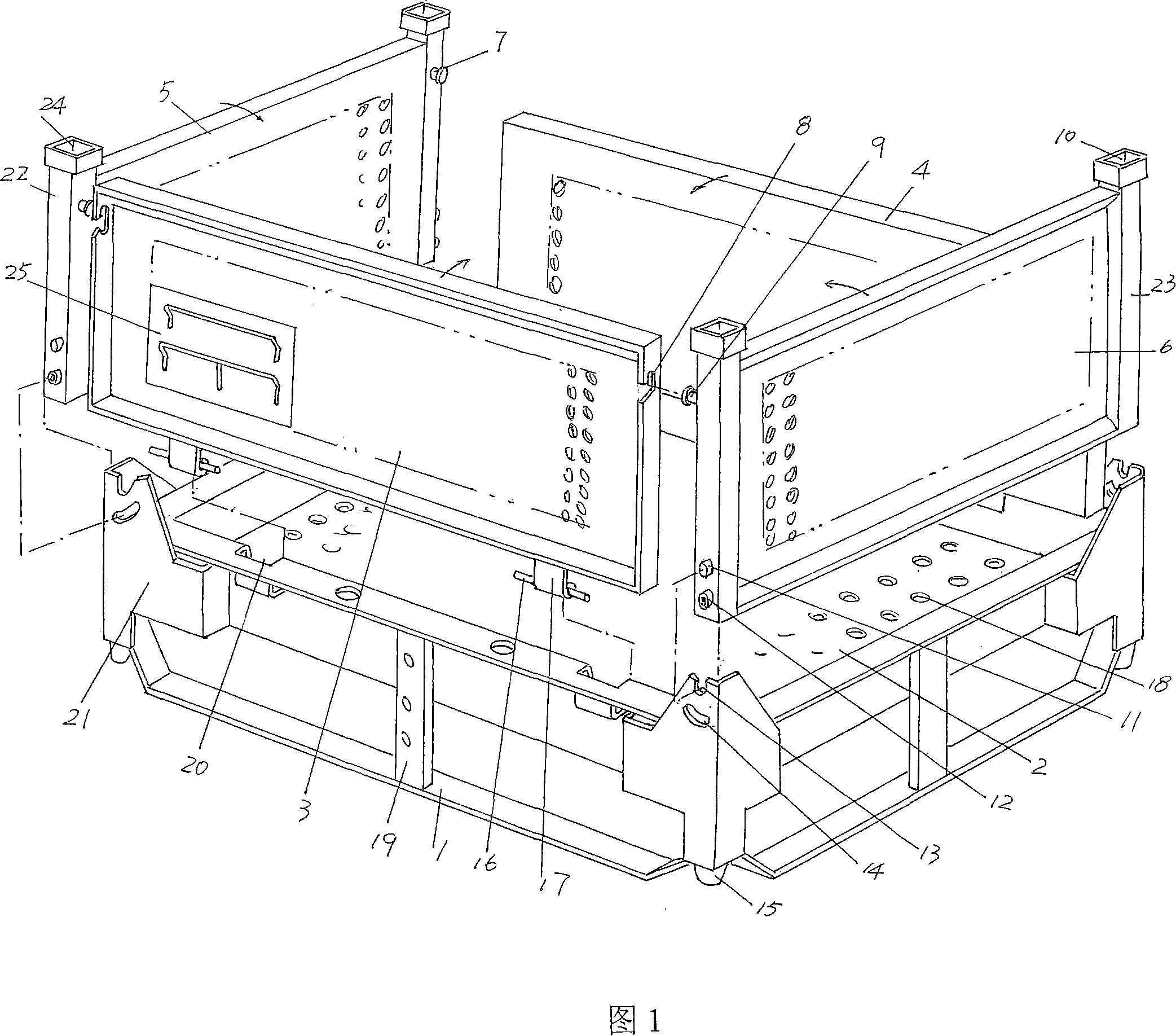

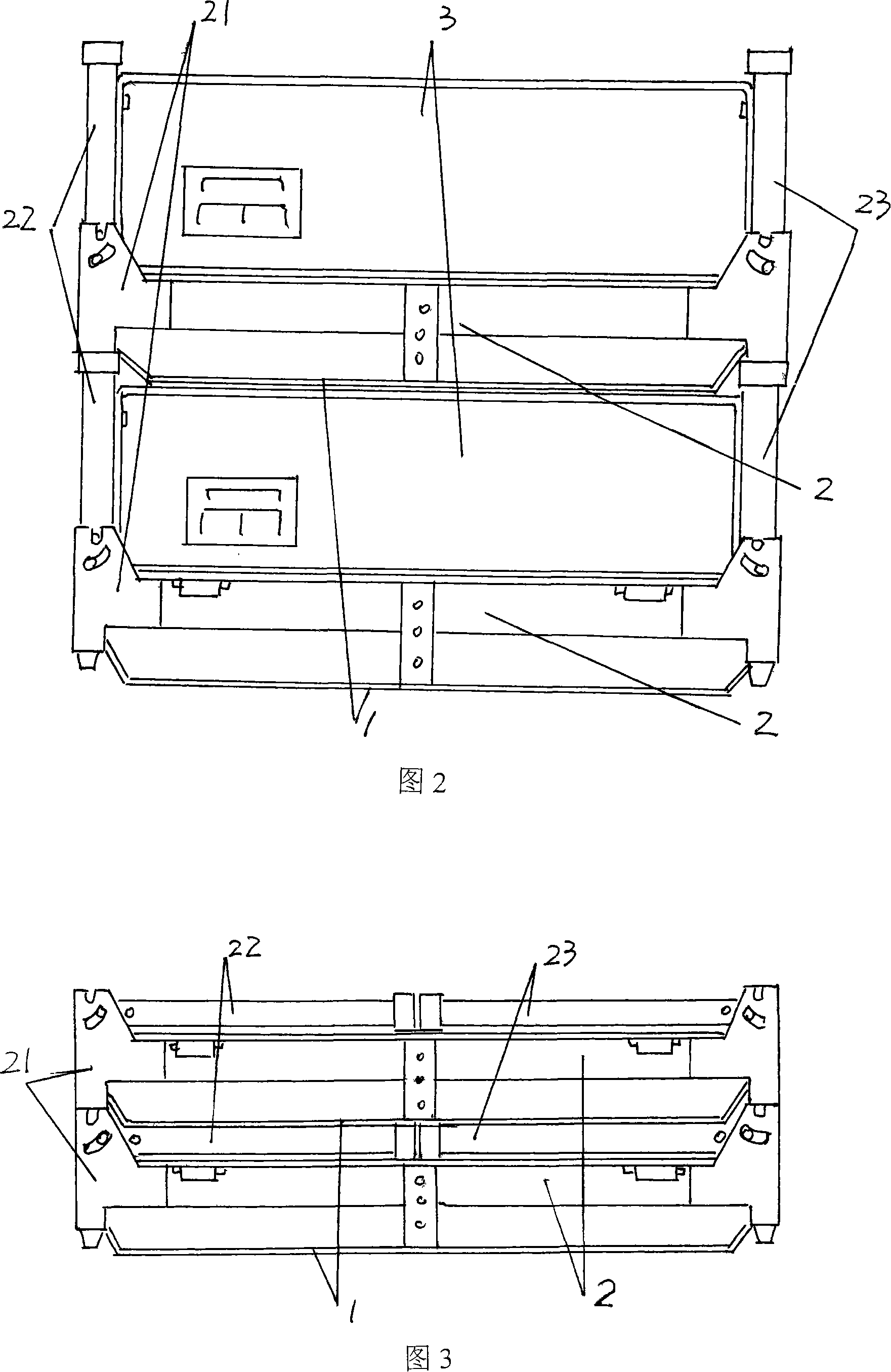

[0021] Referring to Fig. 1, a rectangular base 1 is provided so as to form four right angles, each of the four right angles of the base 1 is provided with a base angle foot 21, and there are mainly two situations for the package described here, One is that when the base 1 is made of plastic, the corner feet 21 of the base are formed in the form of material reinforcement while molding; the other is that when the base 2 is made of metal material, the corner feet 21 of the base are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com