Organic EL component

An electro-luminescence and organic light-emitting body technology is applied in the field of polymer organic electro-luminescence components, which can solve the problems of not breaking through the technical level and strict requirements for the molecular weight distribution of light-emitting layer materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

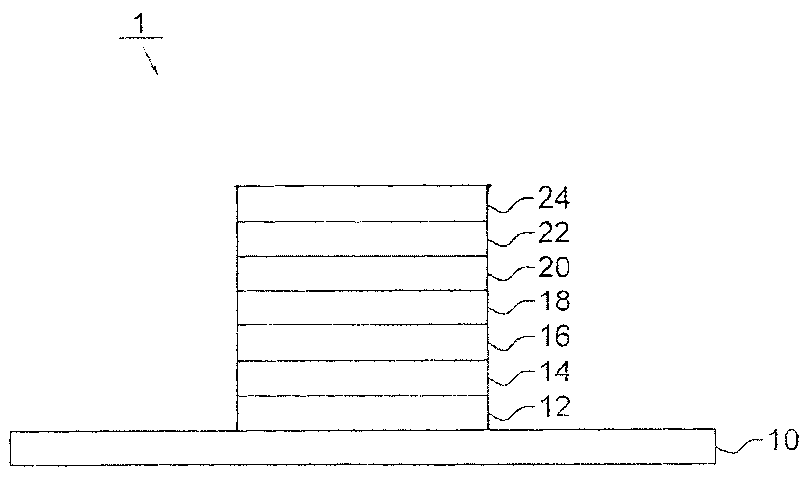

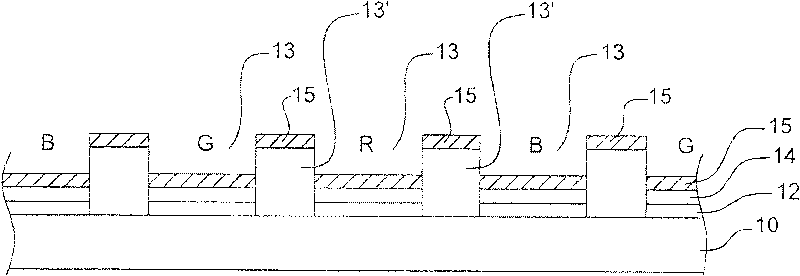

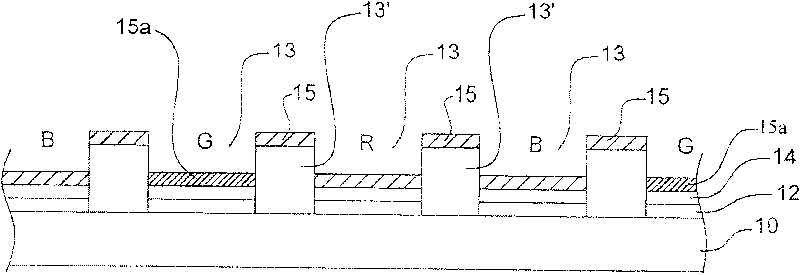

[0041] According to the structure of the above-mentioned specific embodiment, the full-color display device can be produced by the following steps (please refer to Figure 2A-2I ):

[0042] Cleaning the substrate 10 and the first electrode 12 formed thereon: organic solvent and deionized water ultrasonic vibration; nitrogen blow-drying; vacuum drying, the temperature is in the range of about 80°C to about 200°C; ultraviolet light ozone cleaning; oxygen plasma The body (oxygen plasma) is clean.

[0043] Forming the pixel pattern: coating the photosensitive polymer insulating material on the substrate 10 and the first electrode 12, forming the required pixel opening 13 and the insulating wall 13' pattern through the photoresist pattern, and each sub-pixel pattern corresponds to a Organic Electroluminescent Components.

[0044] Forming the hole transport layer 14: coating PEDOT / PSS by spin coating, and baking in an inert gas environment.

[0045] Forming the light-emitting lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com