Resin material for molding and molded product

A technology for resin materials and molded products, applied in the field of molding resin materials and molding products, can solve the problems of inability to obtain high dimensional precision molding resin materials, the range of particle size is not so large, and the molding shrinkage of molded products is not small, etc. Achieve the effects of small forming shrinkage, improved heat dissipation, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0083] Embodiment 1~3, comparative example 1~8

[0084] According to the compounding ratio shown in Table 1, mix each raw material with a mixer, use a 35mmΦ twin-screw extrusion molding machine (manufactured by Ikegai Iron Works, PCM30) with the cylinder temperature set at 300°C, and set the temperature at 300°C , Rotate at 200rpm for uniform melting and kneading to form granules.

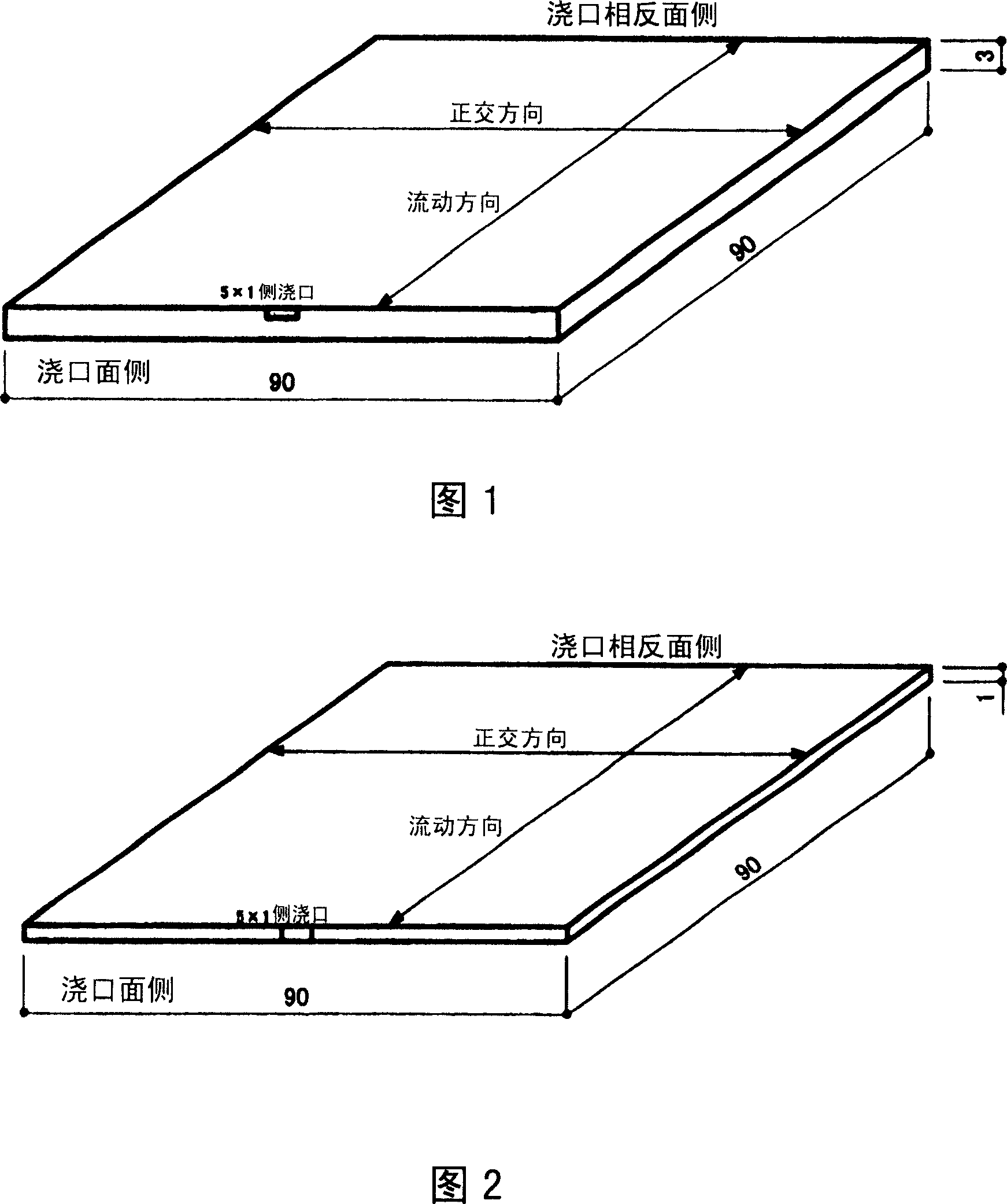

[0085]Each obtained pellet was charged into an injection molding machine (manufactured by Sumitomo Heavy Industries: Promat 100A), and a test piece (side gate, gate size: width 5 mm × height 1 mm) molded product of 90 mm in length × 90 mm in width × 3 mm in height was obtained. , and a test piece (side gate, gate size: width 5mm x height 1mm) molded product of 90 mm in length x 90 mm in width x 1 mm in height.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com