Liquid controlled reversing buffering mechanism and method

A technology of hydraulically controlled reversing and buffering devices, which is applied in fluid pressure actuators, pump control, liquid variable capacity machinery, etc., and can solve the problems of poor position detection accuracy and stability, poor control stability, and affecting the effect of buffer control, etc. problem, to achieve the effect of improving position detection accuracy, good adaptability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

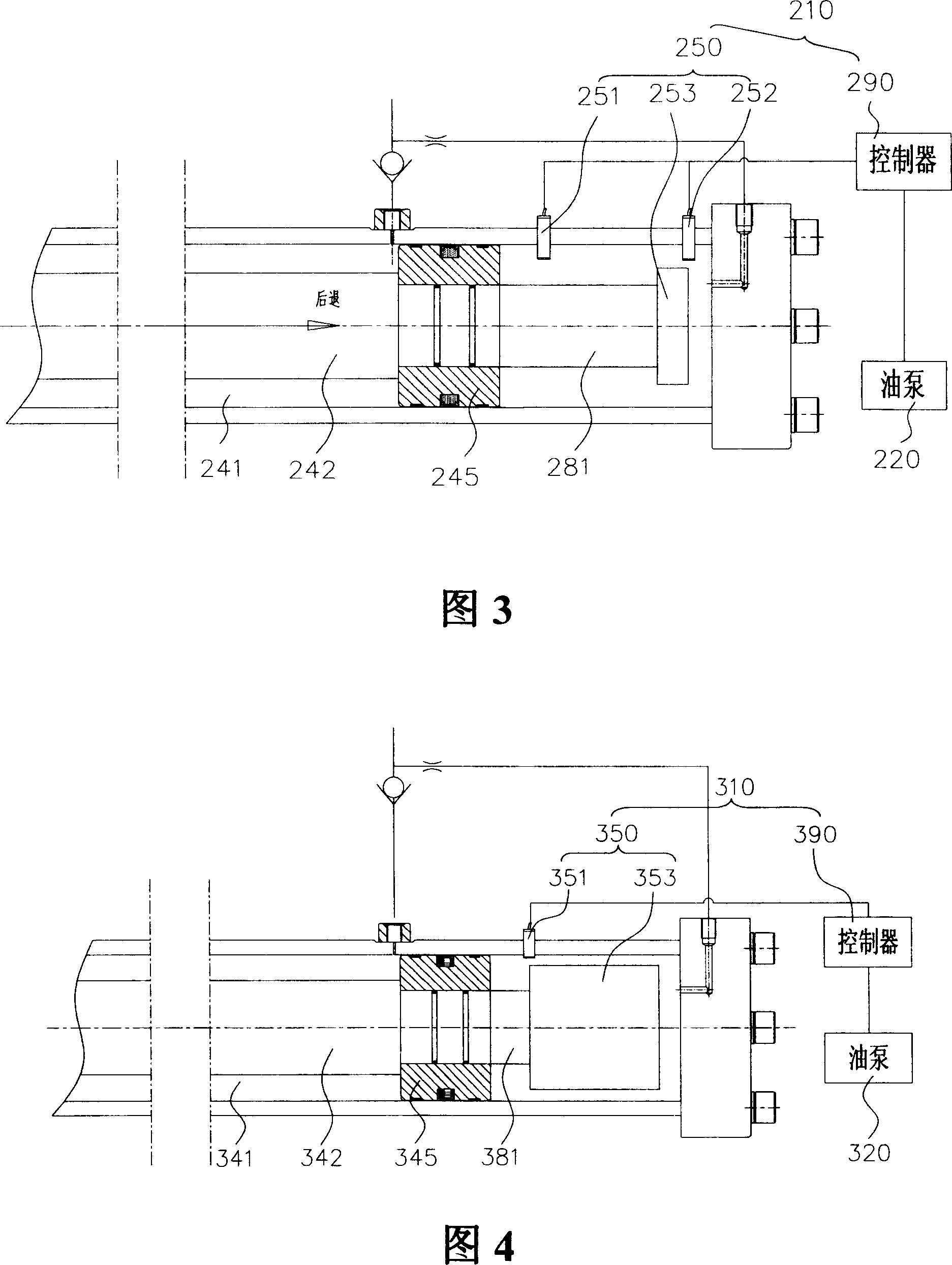

[0020] FIG. 3 shows a reversing buffer device 210 according to a preferred embodiment of the present invention, which includes a position detection device 250 and a controller 290 . The position detection device 250 further includes two position sensors 251 and 252 and an induction block 253 arranged axially on the cavity wall of the oil cylinder 241 . The two position sensors 251 and 252 are separated by a predetermined distance, such as 100mm-200mm, and the position sensor 252 is located near the end of the oil cylinder 241 . One end of the piston 245 is connected with the piston rod 242, and the other end is connected with the induction block 253 through the connecting rod 281. The induction block 253 is preferably a cylinder and has a relatively small thickness, such as 20mm-40mm, and can be connected with the piston. 245 moves together. Wherein, the length of the connecting rod 281 corresponds to the distance between the sensors 251 and 252 .

[0021] As shown in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com