Lithium ion cell injection method using the injecting header

A lithium-ion battery, liquid injection head technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as electrolyte leakage, low efficiency, instability, etc., to prevent leakage, improve production efficiency, The effect of improving the degree of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

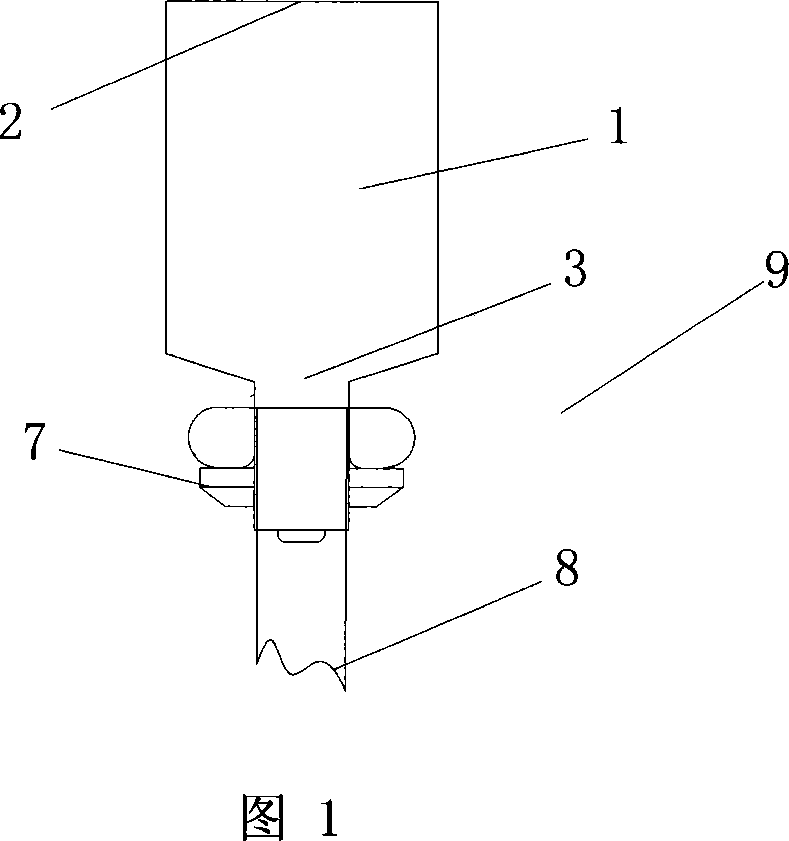

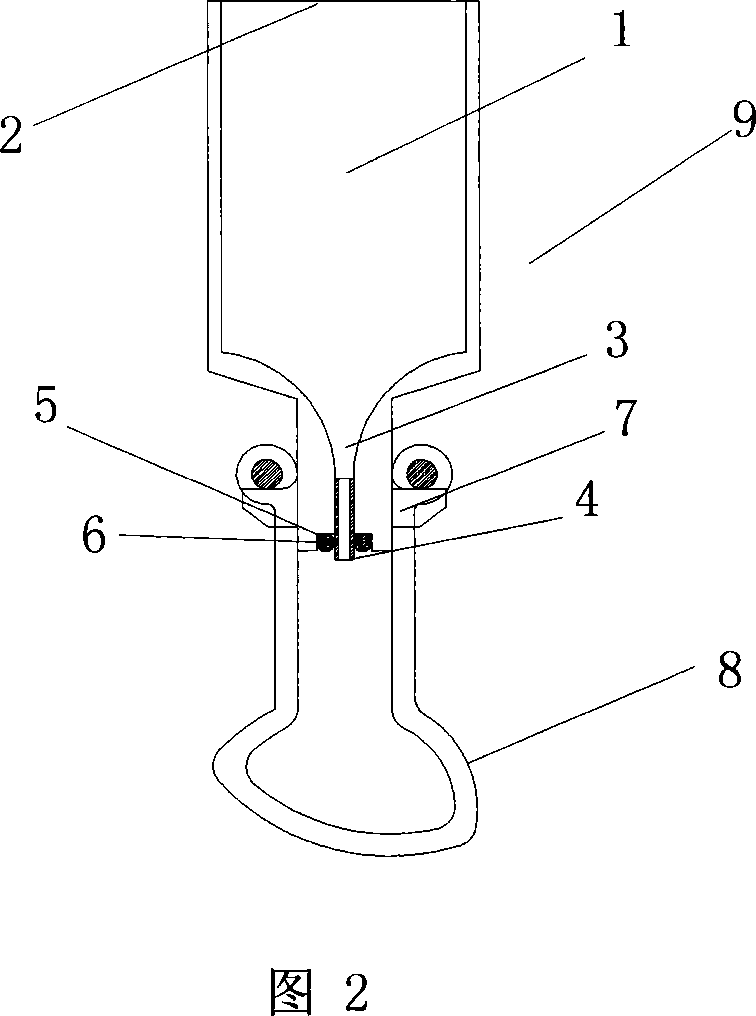

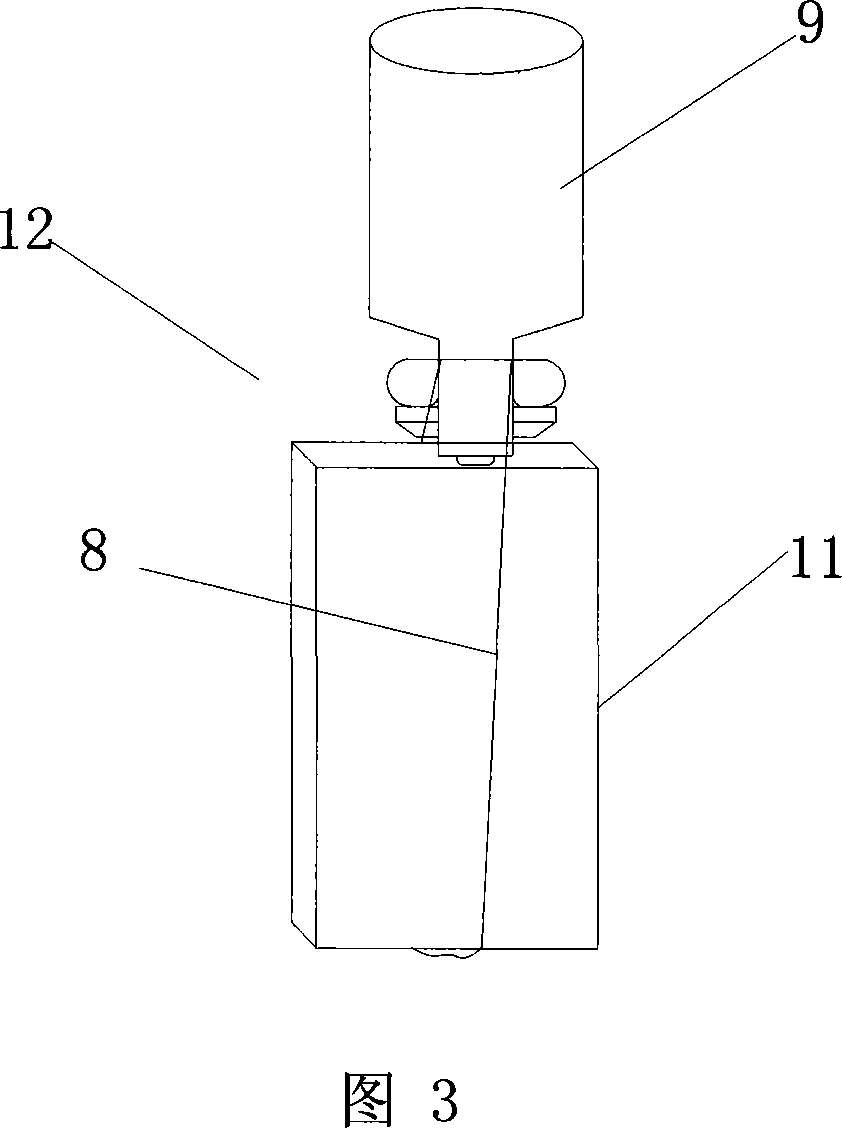

[0017] A liquid injection method for a lithium-ion battery using a liquid injection head is provided, using a liquid injection head with an electrolyte container and an elastic material clamp, as shown in Figures 1 and 2, the liquid injection head 9 includes an electrolyte container 1, an electrolyte container 1. The whole is in the shape of a large top and a small bottom. The liquid inlet 2 is set at the upper end, and the liquid outlet 3 is set at the lower end. The inner side of the liquid outlet 3 is provided with a needle tube 4 matching the battery liquid injection hole. The needle tube 4 is made of stainless steel. As a result, the inner side of the end of the liquid outlet 3 is provided with a sealing groove 5 and a sealing ring 6 around the needle tube 4, which can improve the sealing degree between the needle tube and the battery liquid injection port, and prevent leakage of the electrolyte. The positioning structure on the outside of the liquid outlet 3 It is a boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com