Weighing module

A weighing module and weighing sensor technology, applied in the direction of weighing, detailed information of weighing equipment, instruments, etc., can solve problems such as loss of anti-dumping, damaged bolts, inconvenient maintenance, etc., to achieve small weighing errors and convenient maintenance , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

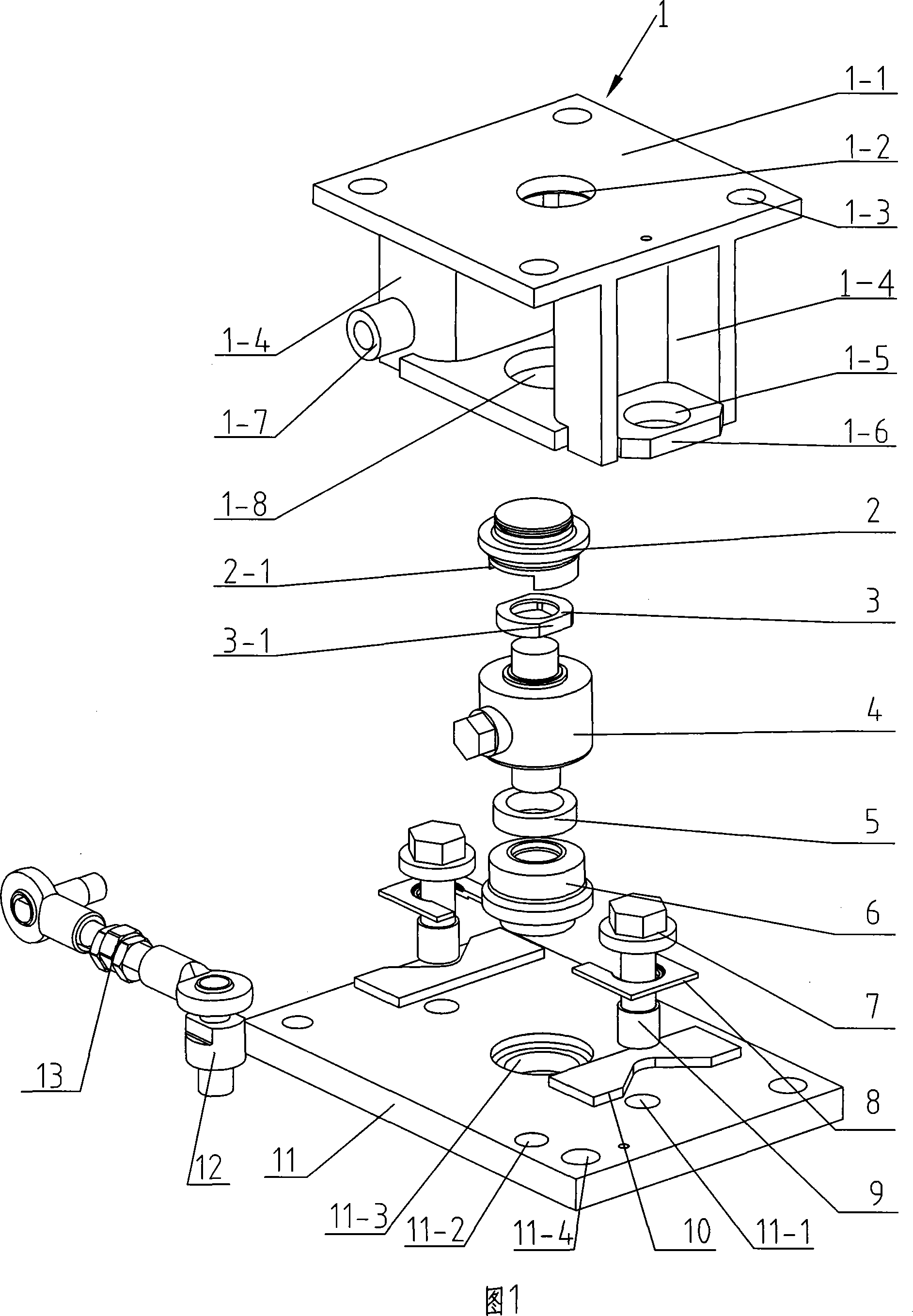

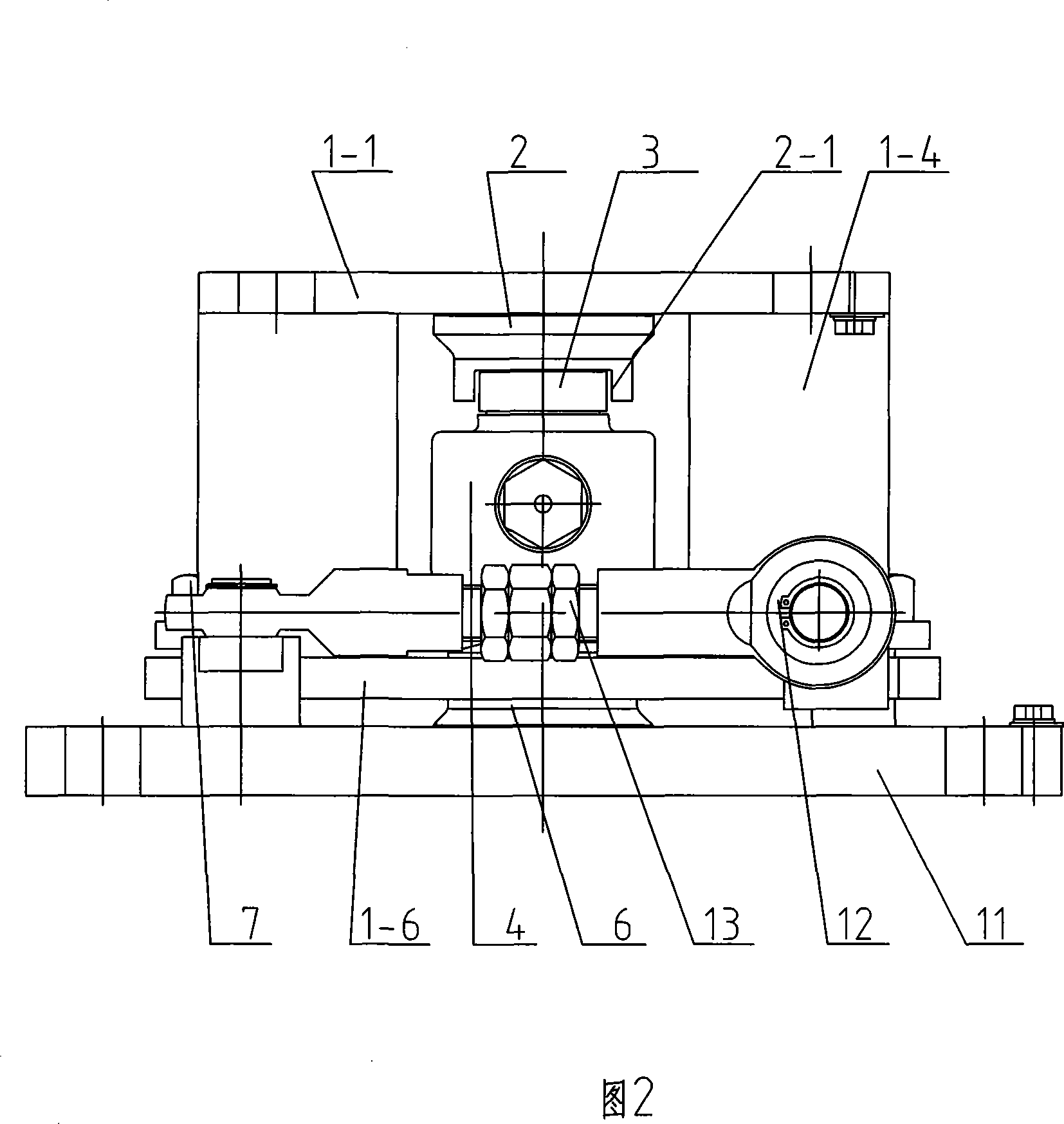

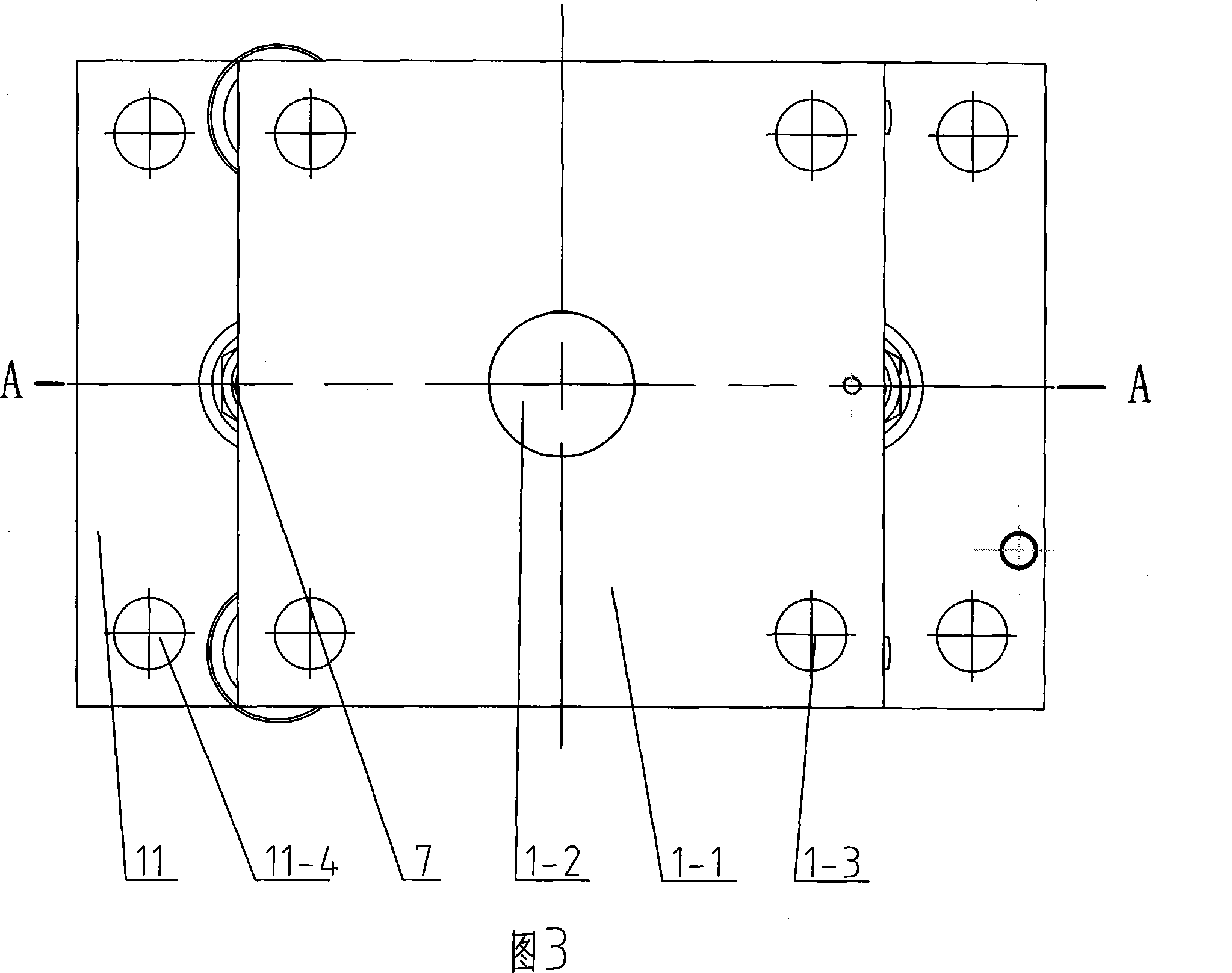

[0017] See the weighing module of the present invention shown in FIGS. 1-4 , which includes a connection assembly 1 , an upper pressure-bearing component 2 , a column load cell 4 , a lower pressure-bearing component 6 and a bottom plate 11 . As shown in Figures 1 and 4, the connection assembly 1 includes a top plate 1-1, a support plate 1-4 and a fixed plate 1-6. The top plate 1-1 is provided with an upper positioning hole 1-2, and the top plate 1-1 is also provided with a There are installation holes 1-3, and containers such as material tanks are installed on the top plate, and two supporting plates 1-4 are connected between the top plate 1-1 and the fixed plate 1-6, in order to improve the mechanical strength and rigidity of the connecting components, The cross section of the support plate 1-4 is U-shaped or C-shaped, the middle part of the fixed plate 1-6 is provided with a limiting hole 1-8, and the two sides of the fixed plate 1-6 are provided with two side holes 1-5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com