Soft soil roadbed settlement monitoring method and device

A technology for settlement monitoring and soft soil subgrade, which is applied in the direction of basic structure engineering, basic structure test, construction, etc., can solve the problems of low monitoring efficiency, damage to the integrity of compacted subgrade, and the inability to continue monitoring, etc., so as to reduce the reference point error and manual error, meet the requirements of low-cost long-term monitoring, simple and reliable measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

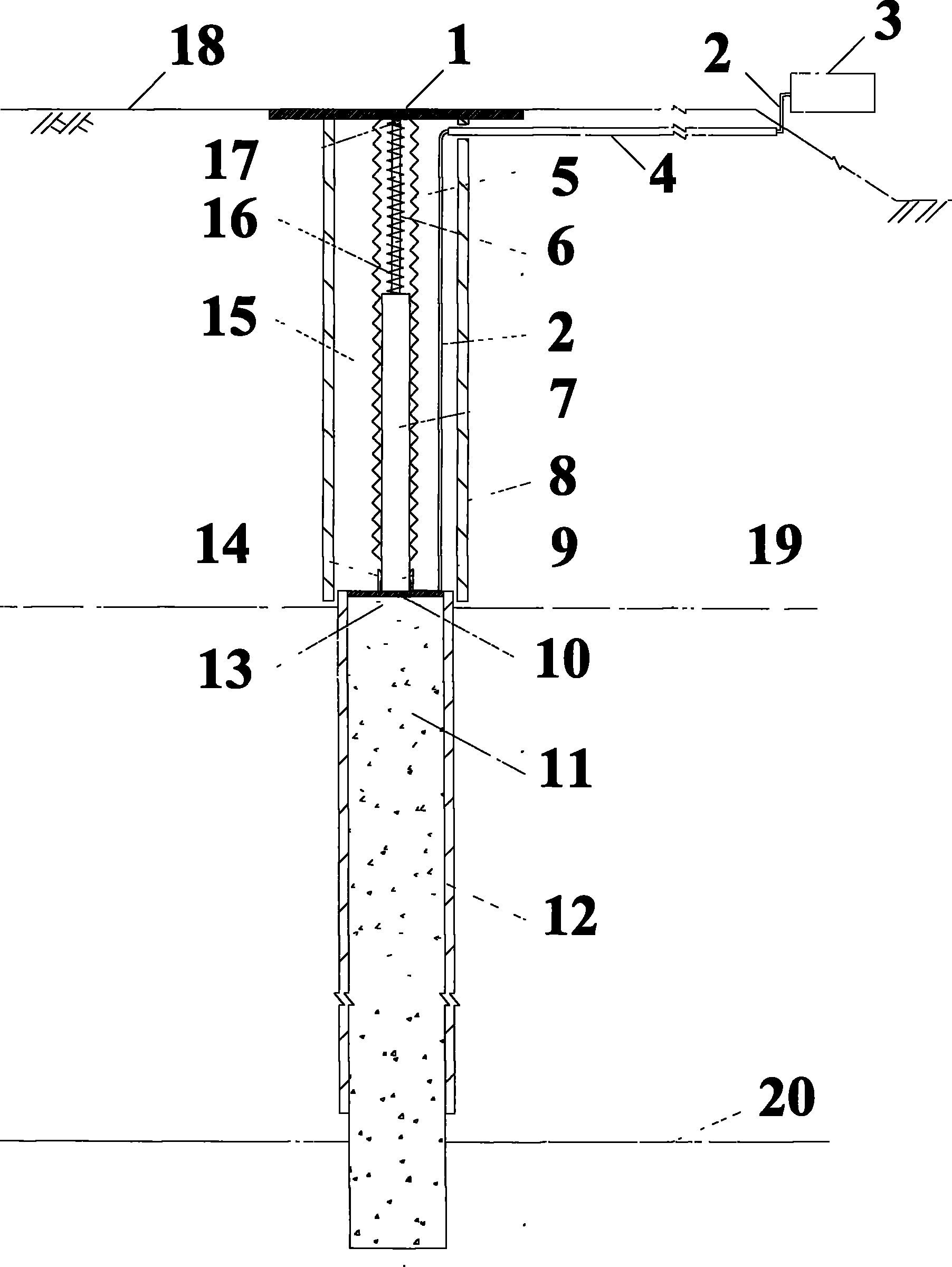

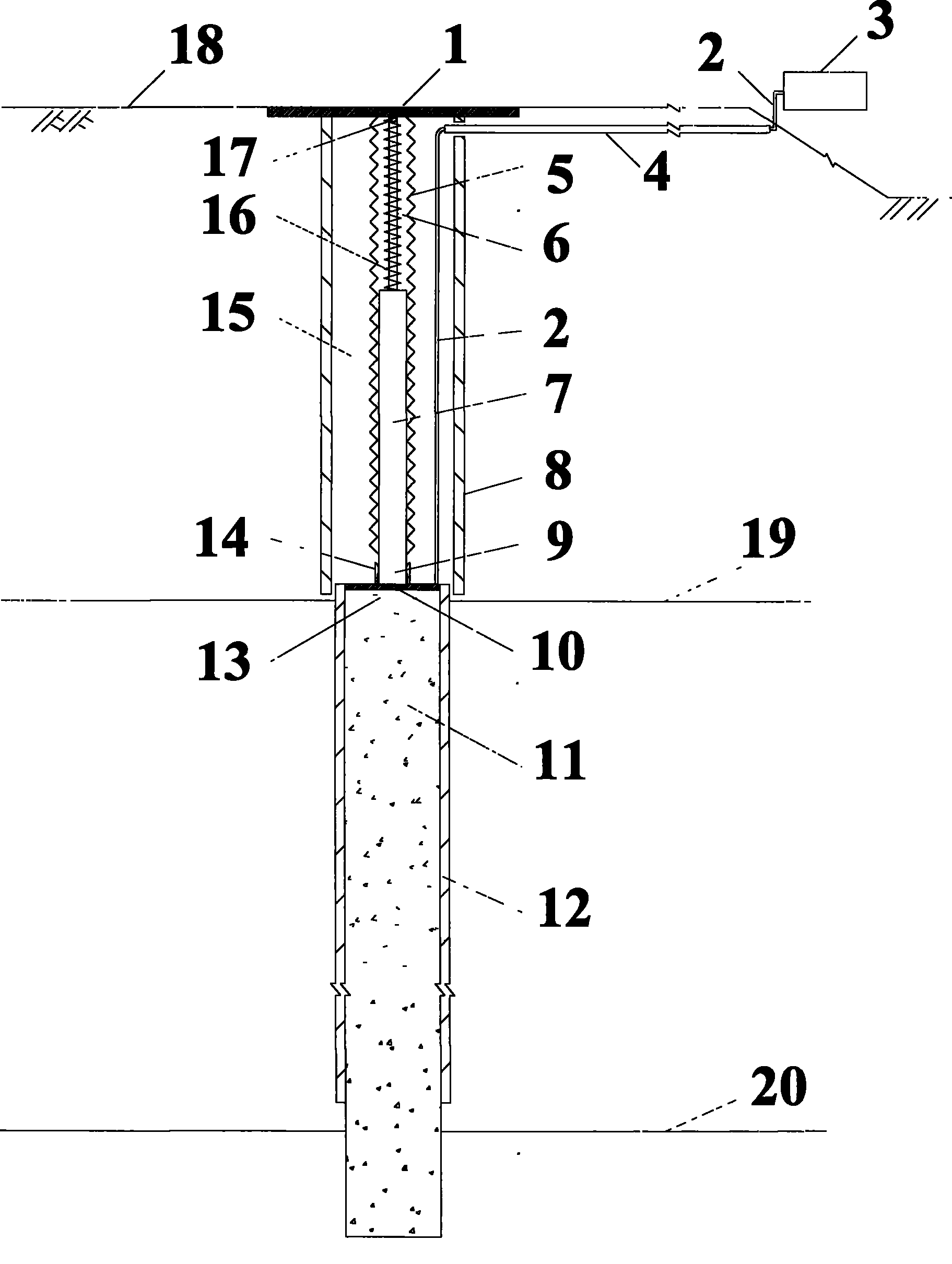

[0029] Details and working conditions of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] This monitoring method is very simple. After installing the monitoring device at one time before construction, directly connect the digital display to the outgoing cable, and read the displacement value in real time. The obtained value is the cumulative settlement of the roadbed in different periods. If equipped with automatic acquisition and When storing equipment, as long as the collection frequency is set, automatic monitoring can be carried out.

[0031] The specific implementation steps are as follows:

[0032] ① Laying of working benchmark piles

[0033] Need to be provided with subgrade position drilling of settlement monitoring point, adopt mud retaining wall during drilling, borehole passes soft soil layer 19, and the bottom of the hole enters certain degree of depth in hard soil layer 20, enters lower layer PVC pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com