Emulating natural porcelain brick machine-shaping material-distributing equipment and method

A technology of processing and imitating nature, which is applied in the direction of ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems of difficult control of certain color materials, repeated production of products, high cost, etc., and achieve natural appearance texture transition and product grade Improve and decorate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

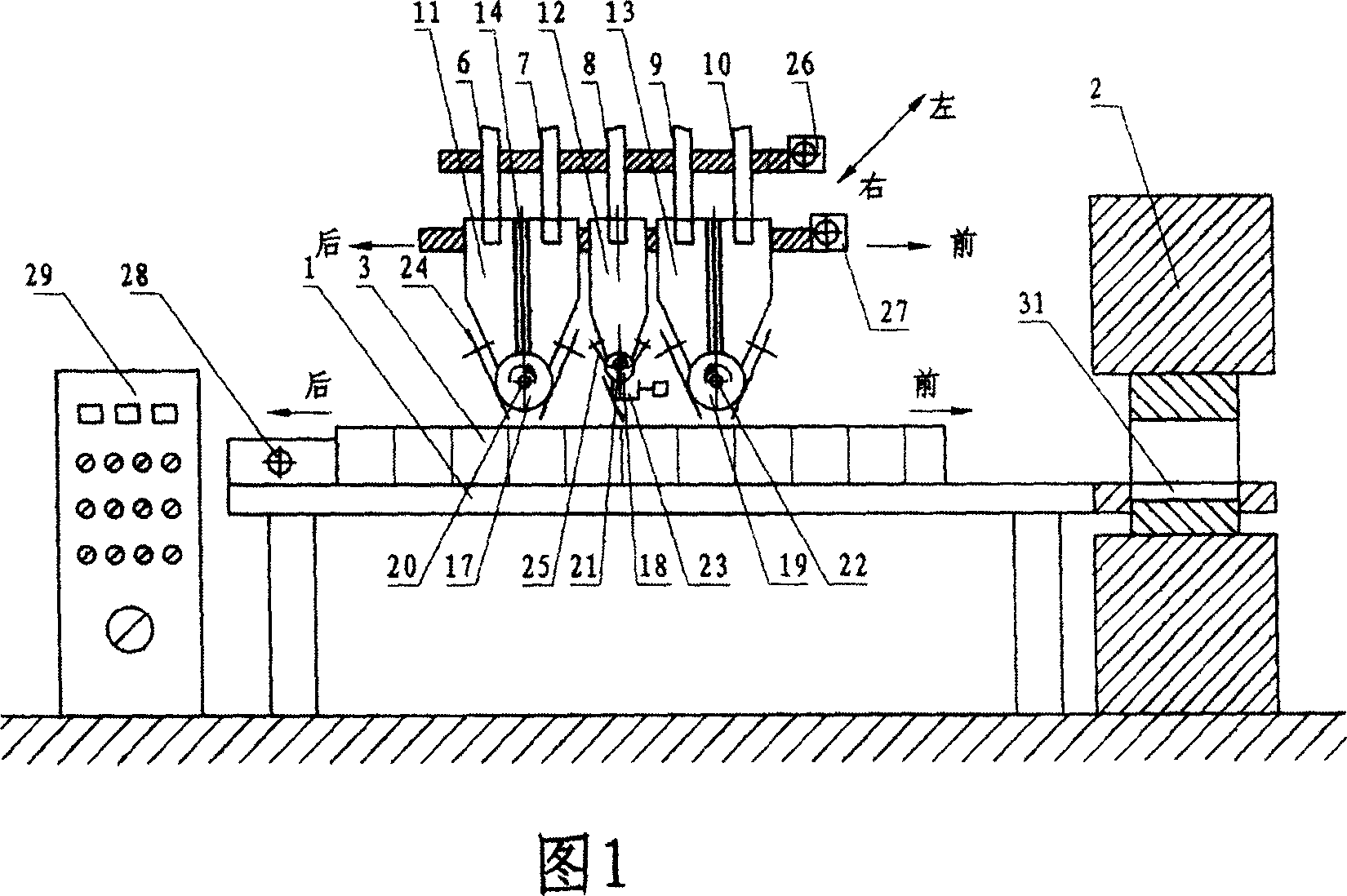

[0033] As shown in Figure 1

[0034]Fig. 1 is the structure schematic diagram of the distributing equipment that imitates natural ceramic tile processing and molding in the present invention. In Fig. 1, the distribution equipment imitating natural ceramic tile processing and forming includes: a feeding base plate 1 with a grid 3 connected to an external electric control device 29, a hydraulic forming machine 2, and the grid 3 for distribution and the grid The driving device 28 is connected; the grid 3 is corresponding to the cloth drum 17, the cloth drum 18, and the cloth drum 19 for the cloth; The hopper 12 and the blanking hopper 13 are connected, and the both sides of the cloth drum 17 and the cloth drum 19 are respectively provided with control blanking baffles 24, and the both sides of the cloth drum 18 are provided with blanking gates 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com