Mild coal-family component separation method based on extraction and back extraction

A separation method and a technology of family components, applied in solid solvent extraction, petroleum industry, solid fuel, etc., can solve the problems of not fully considering the composition characteristics of hydrocarbons, low utilization rate of environmental pollution, etc., to improve the use value and environmental protection Benefits, gentle extraction and stripping, effects of solvent recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

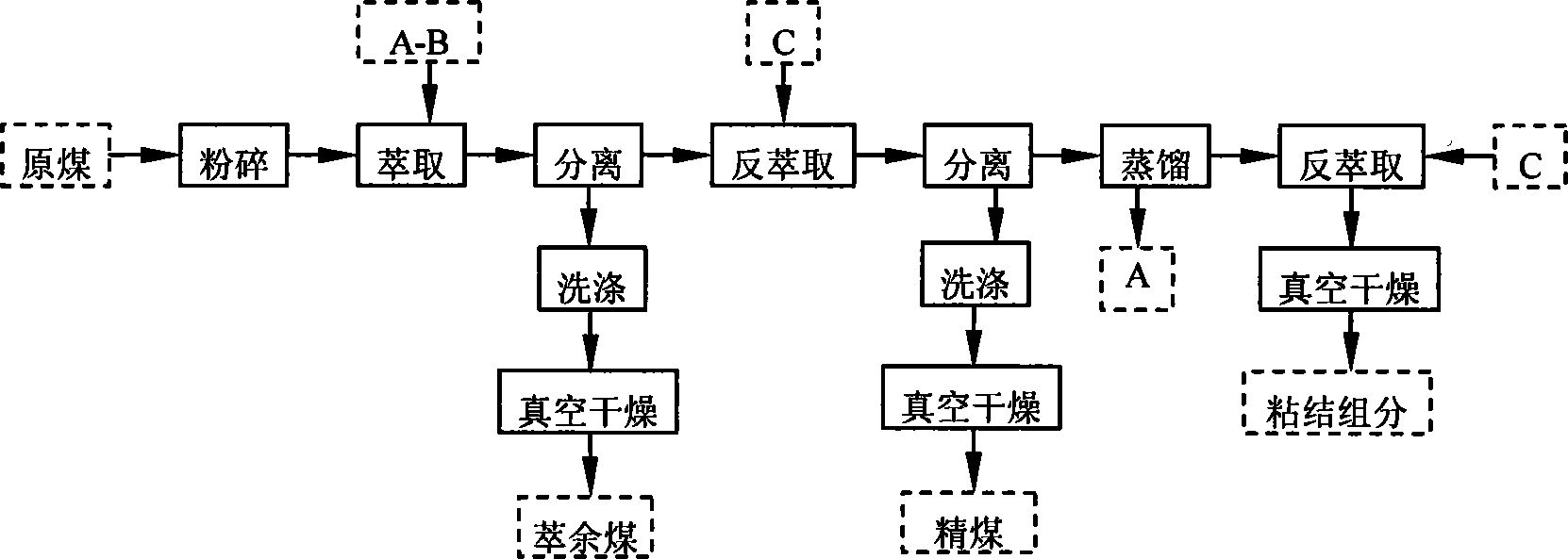

Image

Examples

Embodiment 1

[0024] Embodiment 1: to the coal commodity sample that carbon content is 86.5% (W%, daf), make < 100 mesh coal samples through pulverization, carry out group component separation according to the following steps:

[0025] ①. Put 8g of coal sample in the extractor, then add the mixed solvent, the amount of which is 100ml of mixed solvent per gram of coal sample, add 800mL of mixed solvent, the mixed solvent is a mixture of solvent A and solvent B, the mixed solvent The ratio is 1:1, and the mixing ratio is a volume ratio; solvent A is selected from carbon disulfide, solvent B is selected from N-methyl-2-pyrrolidone, and magnetically stirred at room temperature for 120 minutes, and an extraction process is completed to obtain an extracted solid-liquid mixture ;

[0026] ②. Solid-liquid separation is carried out on the extracted solid-liquid mixture extracted in process ①. The solid-liquid separation adopts the centrifugal separation method, and the extracted solid-liquid mixture...

Embodiment 2

[0038] Embodiment 2: be the coal commodity sample of 85.0% (W%, daf) to carbon content, make <120 mesh coal samples through pulverization, carry out group component separation according to the following steps:

[0039] 1. Place 6g coal sample in the extractor, then add mixed solvent, the amount added is 90 milliliters of mixed solvent per gram of coal sample, the mixed solvent is a mixture of solvent A and solvent B; stir at room temperature for 90 minutes, After one extraction process is completed, the extracted solid-liquid mixture is obtained; the above-mentioned process is repeated 5 times, and the extracted solid-liquid mixture obtained 5 times is combined;

[0040] ②. Solid-liquid separation is carried out on the extracted solid-liquid mixture extracted in the process ①, and the extract and raffinate are respectively obtained after solid-liquid separation;

[0041] ③, the raffinate in the process ② is processed, first washed with water, and then vacuum-dried to obtain th...

Embodiment 3

[0051] Embodiment 3: be the coal commodity sample of 83.9% (W%, daf) to carbon content, make <80 purpose coal samples through pulverization, carry out group component separation according to the following steps:

[0052] 1. Place 10g of coal sample in the extractor, then add mixed solvent, the amount of addition is 110 milliliters of mixed solvent per gram of coal sample, the mixed solvent is a mixture of solvent A and solvent B; stir at room temperature for 60 minutes, The extraction process is completed, and the extracted solid-liquid mixture is obtained; the above-mentioned process is repeated 4 times, and the extracted solid-liquid mixture obtained 4 times is combined;

[0053] 4. Process the extract in the process ②, put the extract into the stripper, then add the stripper to the stripper, the amount of the stripper is equal to 1 by the extract ratio of the stripper: 0.1, the ratio is a volume ratio, stirred at room temperature for 30 minutes, the stripping process is ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com