Device for upsetting and crimping

A curling and driving device technology, applied in the field of stuffing and curling devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

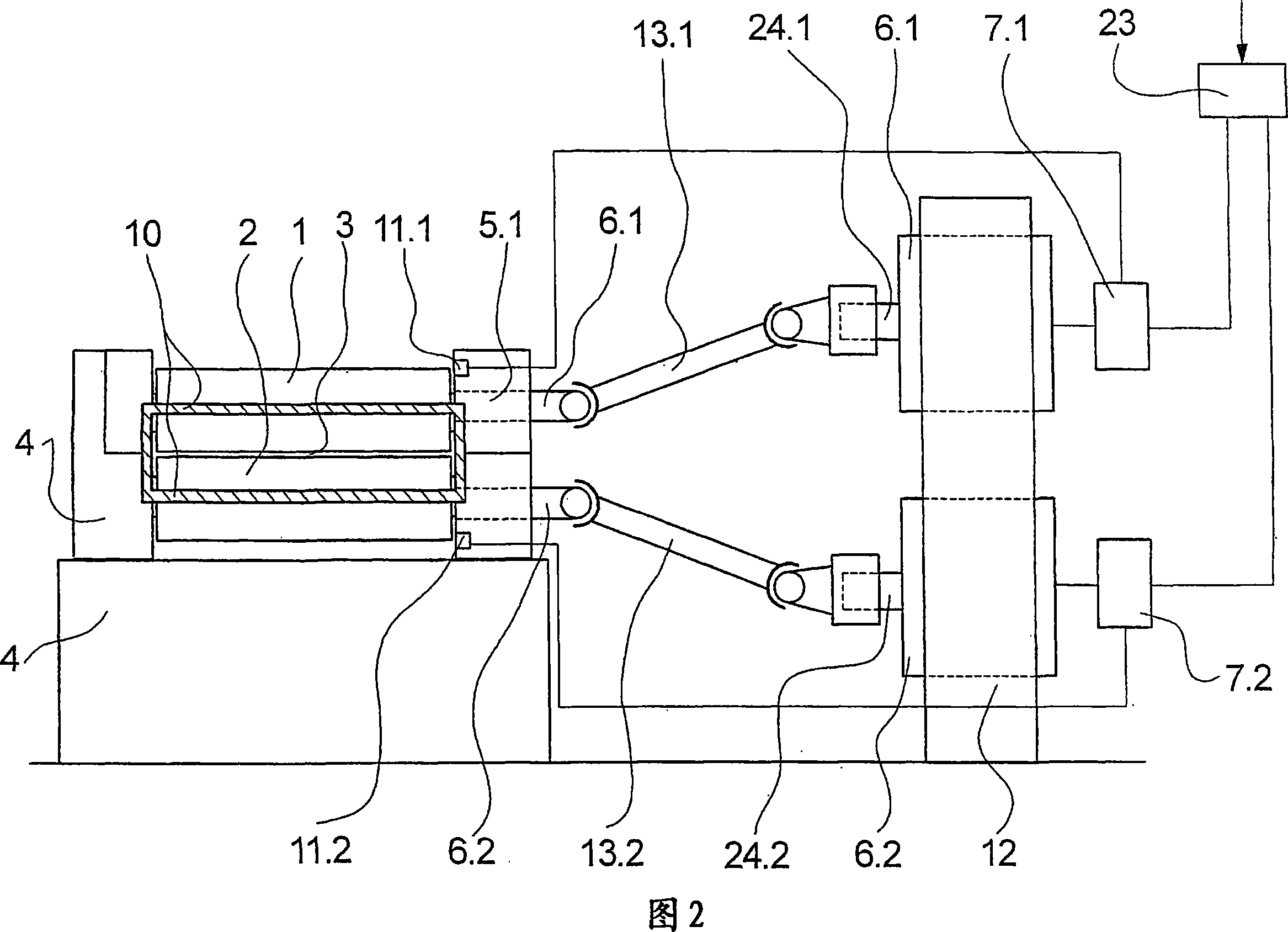

[0024] FIG. 1 shows schematically a first exemplary embodiment of the device according to the invention in a view.

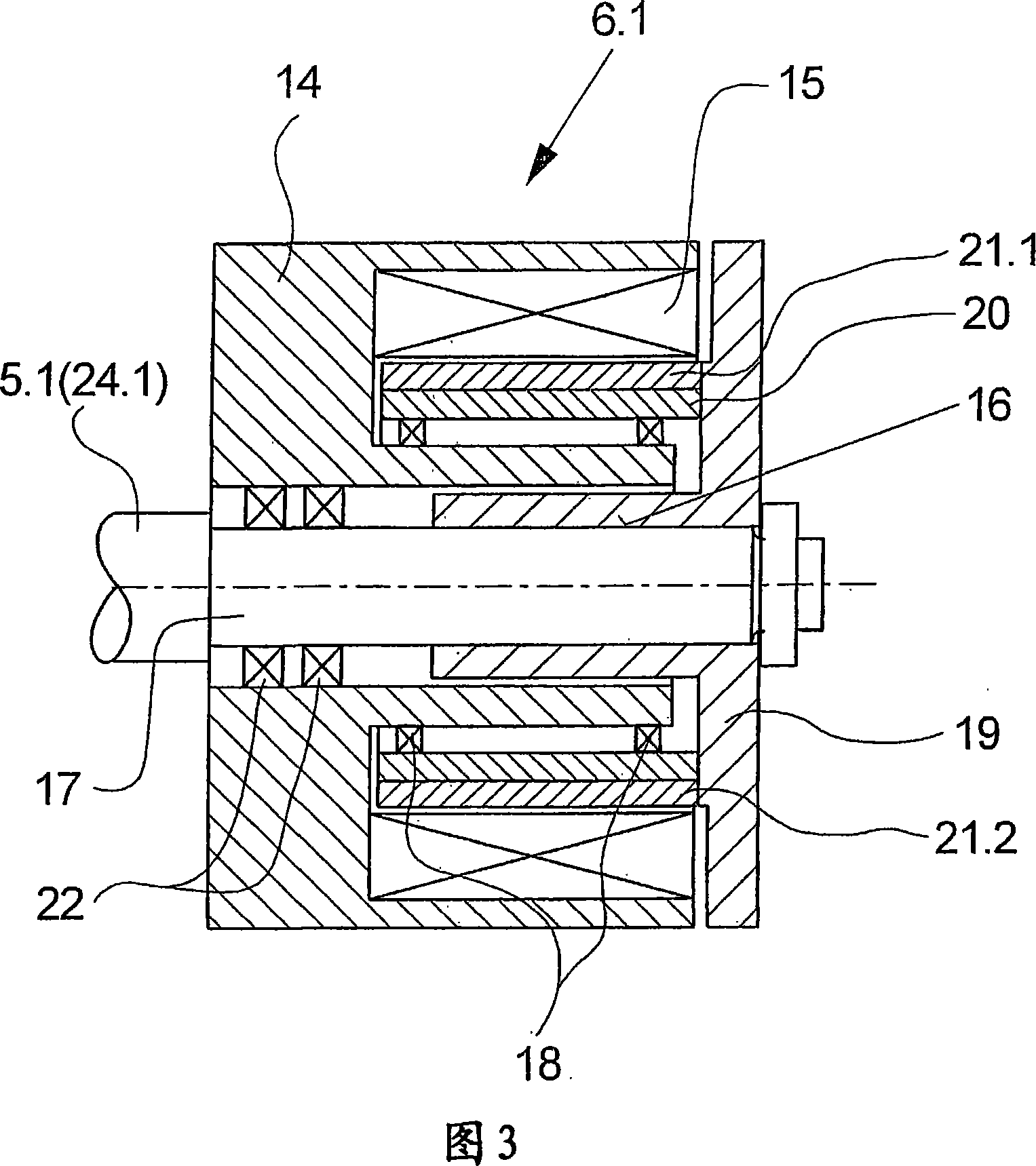

[0025] The device for stuffing and crimping synthetic fibers essentially comprises two rolls 1 and 2 mounted rotatably in a machine frame 4 and a stuffing box 10 arranged downstream of the rolls 1 and 2 . FIG. 1 shows a stuffer box 10 connected downstream of the rollers 1 and 2 in a transverse section. A roll gap 3 is formed between the upper roll 1 and the lower roll 2 to enable the fiber product to be pulled in and crimped by bending. Each roller 1 and 2 is connected to a drive shaft 5.1 and 5.2. The drive shaft 5.1 of the upper roller 1 is directly connected to the motor 6.1 at the drive end. The lower roller 2 is directly connected to the second motor 6.2 via the drive shaft 5.2.

[0026] In order to adjust the roll gap 3 between the rolls 1 and 2, the distance between the rolls 1 and 2 can be varied. For this purpose, the upper roller 1 with the drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com