Auxiliary-handle fixing clip for modular headliner of automobile

A technology for fixing clamps and auxiliary handles, which can be used in special positions of vehicles, vehicle components, transportation and packaging, etc., and can solve problems such as weakening of bending moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

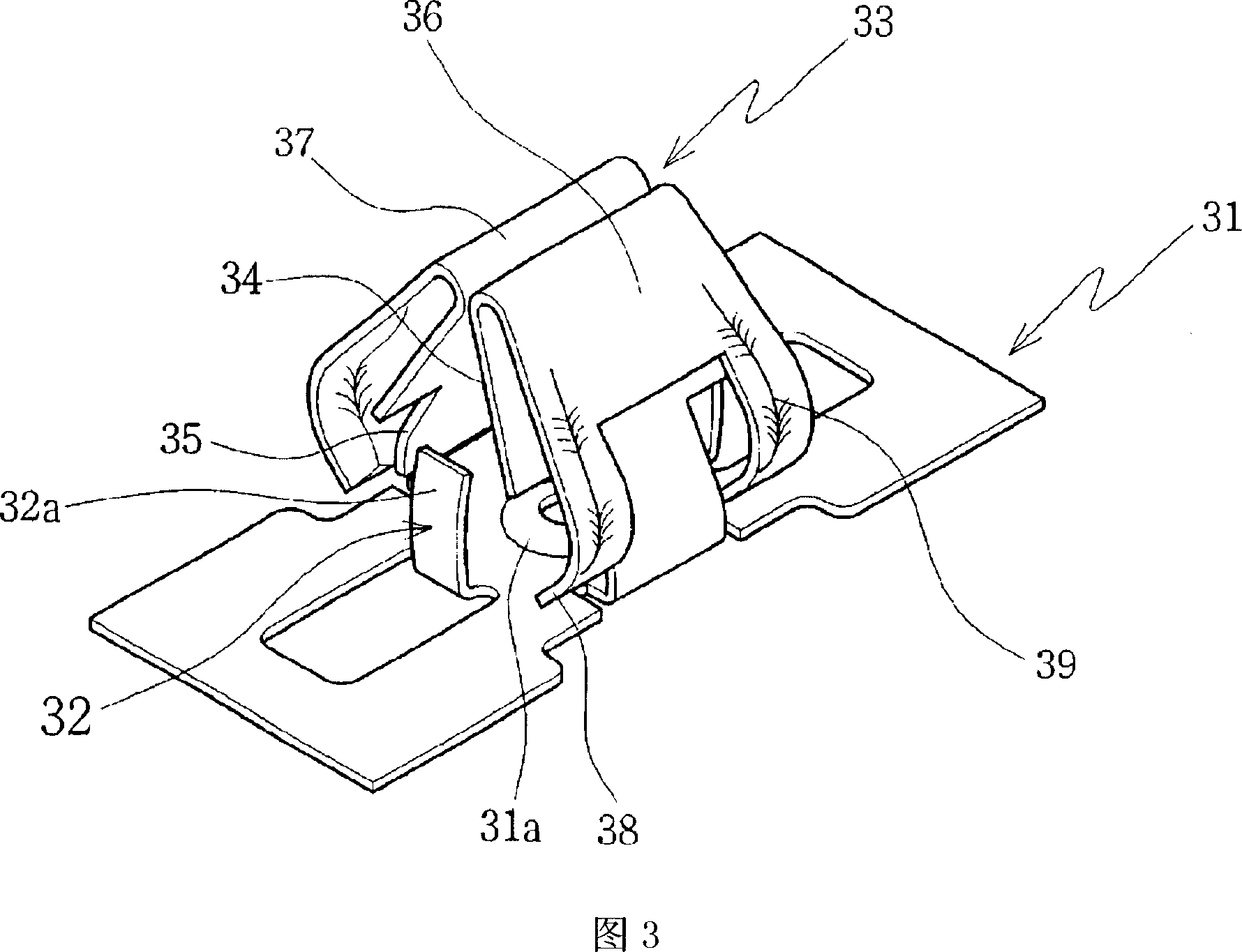

[0030] According to the above-mentioned first embodiment of the present invention, when the fixing fixture is inserted, the hook 33 at the front part enters the engaging hole 11 of the vehicle body panel 10, and the outer walls 36 located on both lateral lateral sides of the hook 33 are inserted into the engaging hole 11, so that The outer walls 36 shrink in directions facing each other and closely contact the inner wall surfaces of the engagement holes 11 . After completion of the insertion in the engaging hole, the outer wall 36 elastically recovers or expands outward, so that the lower engaging member 38 can contact the outer surface of the vehicle body panel 10, and the support tongue 38a is engaged on the peripheral surface 11a of the engaging hole 11, by This ensures firm fixation not only in the vertical direction but also in the horizontal direction.

[0031] Even if the two engaging parts 38 bent downwards and inwards from the bottom of the outer wall 36 are elastical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com