Method and apparatus for scribing brittle material board and system for breaking brittle material board

The technology of a brittle material substrate and a scribing device is applied in the fields of scribing and scribing devices for brittle material substrates and cutting systems for brittle material substrates, which can solve the problems of scribing lines that cannot be formed straight, and achieve the effect of expanding the scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

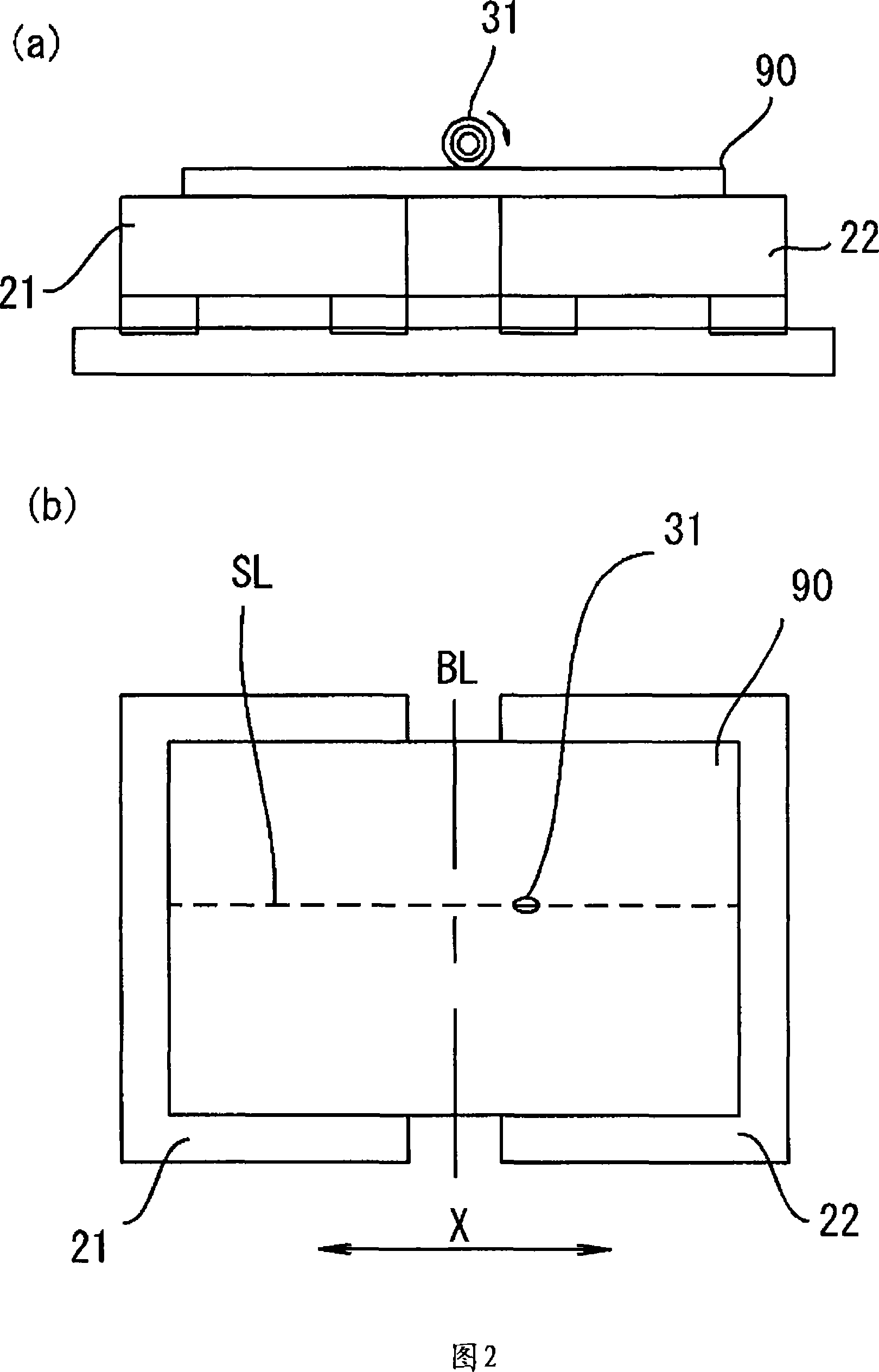

[0082] In the first embodiment, an example of a scribing method is shown in which internal stress in the vicinity of a line to be scribed is made uniform by compressing or stretching a brittle material substrate in the same direction as the scribing direction.

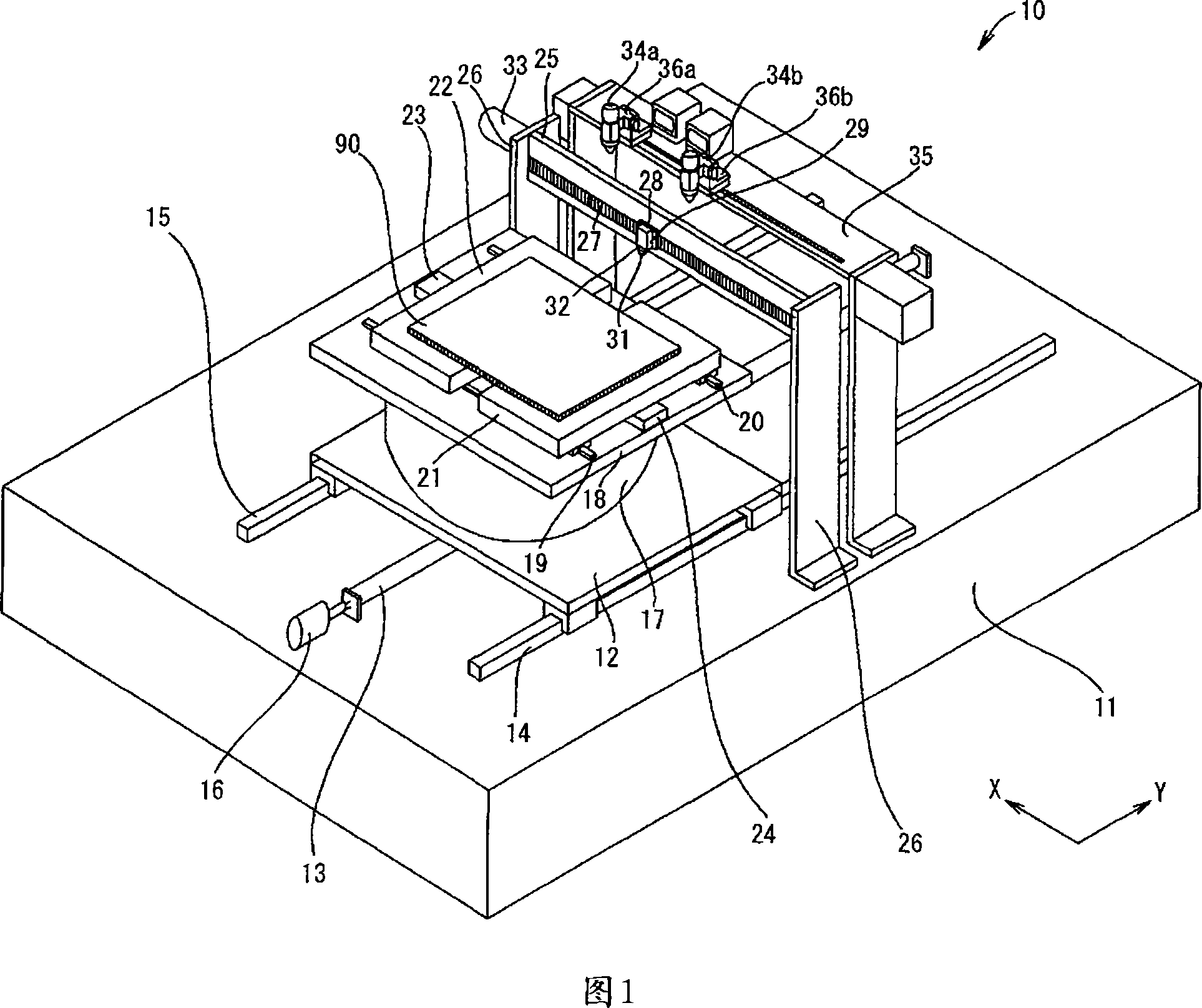

[0083] FIG. 1 is a perspective view showing a schematic configuration of a scribing device according to the present invention. This scribing device 10 is a device for forming scribing lines on a mother glass substrate 90 . As shown in FIG. 1 , the scribing device 10 includes a slide table 12 that reciprocates in the horizontal direction (Y-axis direction in the figure) along a frame 11 .

[0084] The slide table 12 is slidably supported along a pair of horizontal guide rails 14 and 15 which are arranged on the upper surface of the frame 11 in parallel to each other along the Y-axis direction. On the intermediate portion of the two guide rails 14 and 15 , a ball screw 13 parallel to the guide rails 14 and 15 and rotate...

no. 2 approach

[0102] In the second embodiment, an example of a scribing method for uniformizing internal stress near a line to be scribed is shown by compressing or stretching a brittle material substrate in a direction perpendicular to the scribing direction. In addition, in this example, an example of a scribing device including an internal stress detection mechanism is shown.

[0103] Fig. 3 is a schematic configuration perspective view showing another embodiment of the scribing device of the present invention. This scribing device 40 is similar to that shown in FIG. The scribing device of the first embodiment is not different in configuration, so detailed descriptions of the same members are omitted by using the same symbols for them.

[0104] A pair of first holding table 41 and second holding table 42 that reciprocate in the Y-axis direction in a horizontal state are provided on the upper surface of small table 18 . The first holding table 41 and the second holding table 42 are supp...

no. 3 approach

[0124] In the third embodiment, the scribing line is shown in which the internal stress in the vicinity of the planned scribing line is made uniform by compressing or stretching the brittle material substrate in a direction inclined 45 degrees to the horizontal direction with respect to the scribing line direction. An example of a device.

[0125] Fig. 6 is a schematic configuration perspective view showing another embodiment of the scribing device of the present invention. In addition to the configuration of the first holding table and the second holding table, and the moving directions of the first holding table and the second holding table, the scribing device 60 is relative to the X axis perpendicular to the sliding direction of the sliding table 12. Except for the state where the direction is set at an inclination angle of 45 degrees, there is no structural difference from the scribing device of the second embodiment shown in FIG. 1 , so detailed descriptions of the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com