Station panel

A panel and station technology, applied in the field of auxiliary equipment of clean workshop production line, can solve problems such as affecting the performance of components, and achieve the effect of weakening influence, eliminating mutual influence and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings and examples.

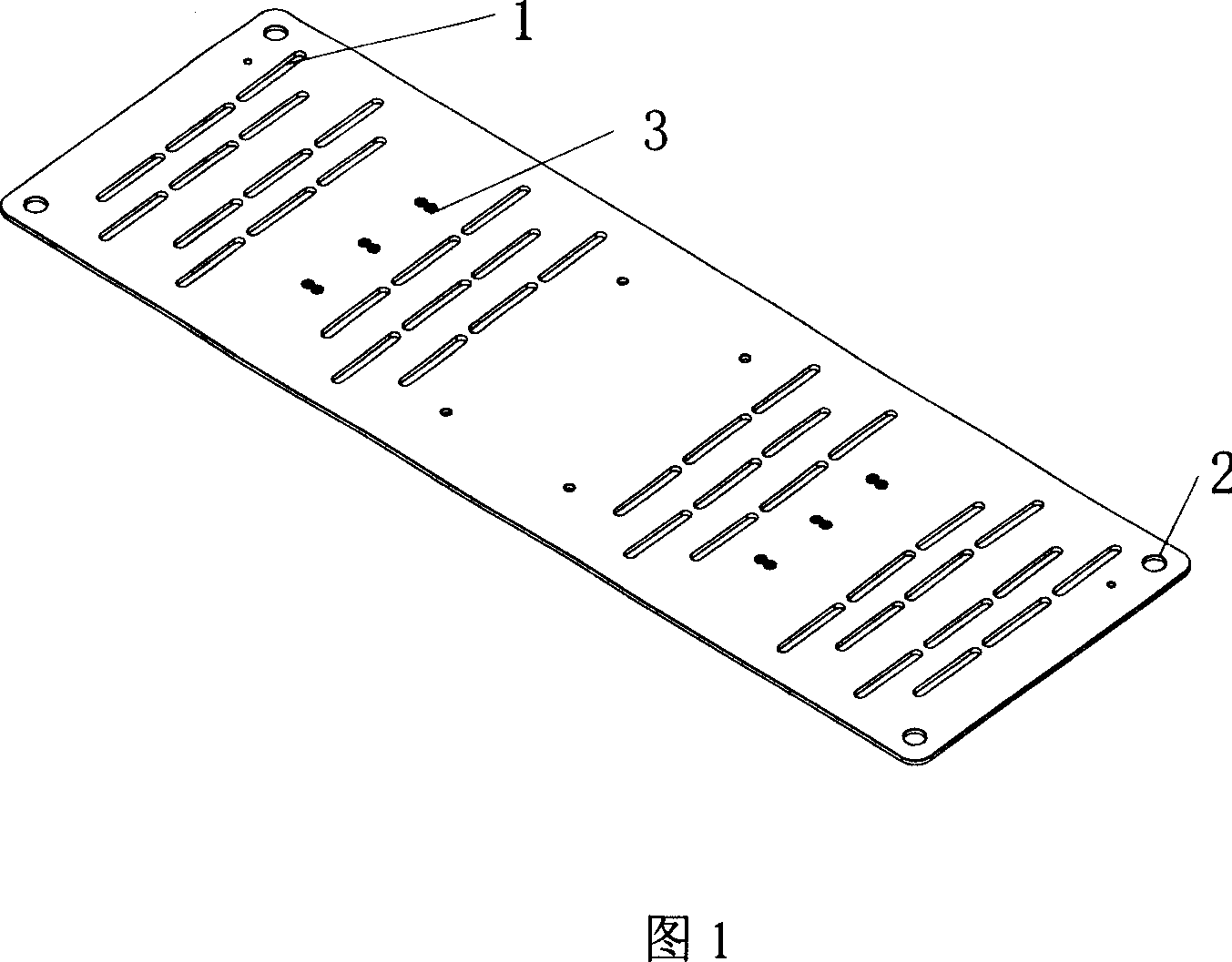

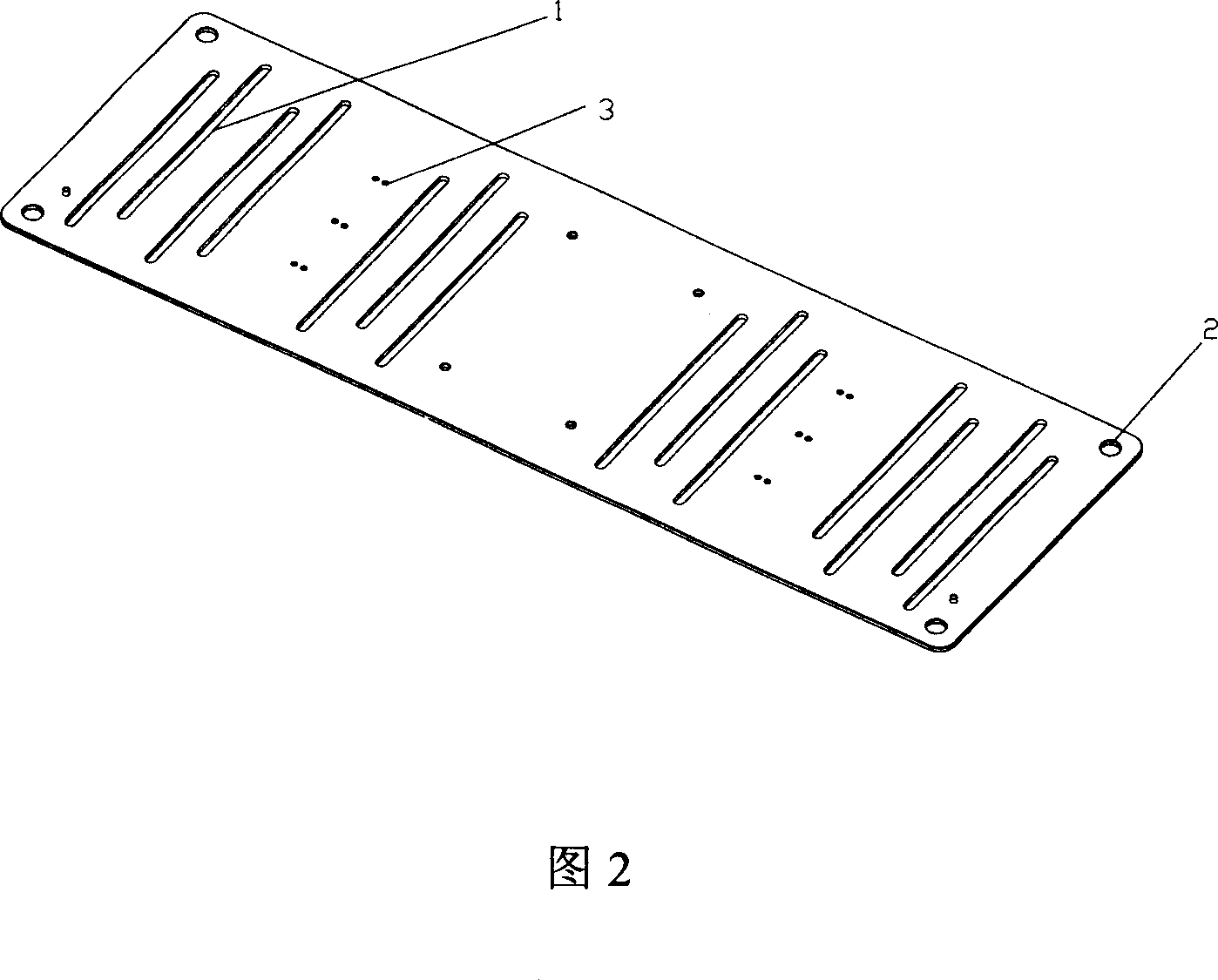

[0019] As shown in FIG. 1 , a workstation panel used in a disk production workshop is preferably implemented. The panel is provided with a gas guide groove 1 , a panel positioning hole 2 and a fixture installation hole 3 . The gas diversion grooves are parallel to each other, and three gas diversion grooves are arranged at a parallel position. When the station panel is installed on the workbench, the groove direction and the conveying direction of the conveyor belt form an included angle which is preferably a right angle. In order to ensure that the airflow between two adjacent grooves will not inhibit each other, the distance between the parallel gas guide grooves is at least twice the narrow side of the grooves, which can form the effect of mutual promotion of the airflows and make the gas flow more smoothly. The gas diversion grooves are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com