Organic soil conditioner prepared with city sludge and its usage

A technology for organic soil and urban sludge, applied in organic fertilizers, soil conditioning materials, sewage/sludge fertilizers, etc., can solve problems such as harm to human health, stunted seed growth, and the formation of pests and diseases, and achieves less nutrient loss, improved environmental protection. The effect of crop product quality and crop yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

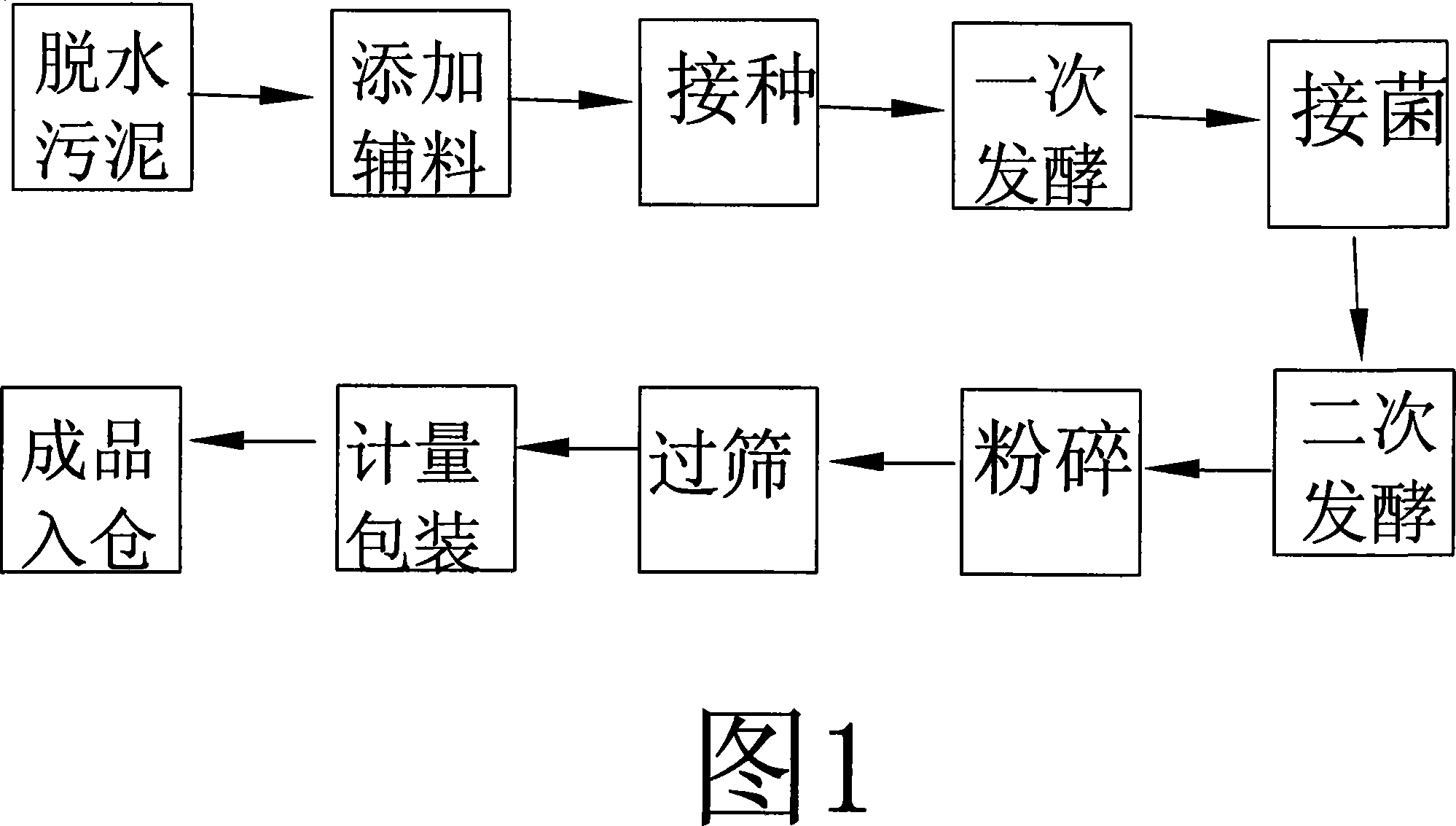

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix 600kg of dewatered sludge with a moisture content of 75% and 90kg of dried straw (crushed below 5mm) with a moisture content of 10% in a volume ratio of 1:3 to make it uniformly mixed into a mixture with a moisture content of 55%. .

[0035] (2) The above-mentioned mixed materials and inorganic auxiliary materials: 50kg of alkali slag powder (over 100 mesh), 20kg of zeolite powder (over 100 mesh); fertilizer balance agent: 10kg of monosodium glutamate waste residue; 5kg of enzyme bacteria quick rot agent and mix evenly. The water content is 52%, the C / N is 25:1, the organic matter content is 32%, and the pH value is about 7.5.

[0036] (3) Stack the above-mentioned compost materials, the height of the stack is 1.5m, and the width is 3.0m. The first fermentation time is 7 days. .

[0037] (4) Transfer the material after the first fermentation into the storage bin of the heated kang system, add 10kg of VT-1000 bacterial agent to carry out the second fermentation...

Embodiment 2

[0040] (1) Mix 680kg of dewatered sludge with a moisture content of 70% and 120kg of dried rapeseed cake (crushed below 5mm) with a moisture content of 14% in a volume ratio of 1:3 to make it uniformly mixed to a moisture content of 52% mixture.

[0041] (2) The above-mentioned mixed materials and inorganic auxiliary materials: 90kg of fly ash (over 100 mesh), 40kg of bentonite powder (over 100 mesh); fertilizer balance agent: 10kg of alcohol waste residue; 5kg of enzyme bacteria quick rot agent and mix evenly. The water content is 52%, the C / N ratio is 28:1, the organic matter content is 33%, and the pH value is about 8.0.

[0042] (3) Stack the above-mentioned compost materials, the height of the stack is 1.5m, and the width is 3.0m. The first fermentation time is 7 days, and the temperature rises to 55-58°C for the first time, and then every 2 days.

[0043] (4) Transfer the material after the first fermentation into the storage bin of the heated kang system, add 10kg of V...

Embodiment 3

[0046](1) Mix 650kg of dewatered sludge with a moisture content of 80% and 110kg of dried bean cakes with a moisture content of 11% (crushed below 5mm) in a volume ratio of 1:3, making them evenly mixed into a mixture with a moisture content of 57% .

[0047] (2) The above-mentioned mixed materials and inorganic auxiliary materials: 70kg of lime powder (over 100 mesh), 30kg of zeolite powder (over 100 mesh); fertilizer balance agent: 20kg of sugar refining waste residue; 5kg of enzyme bacteria quick rot agent and mix evenly. The water content is 54%, the C / N ratio is 24:1, the organic matter content is 36%, and the pH value is about 8.0.

[0048] (3) Stack the above-mentioned compost materials, the height of the stack is 1.5m, and the width is 3.0m. The first fermentation time is 7 days, and the temperature rises to 55-58°C for the first time, and then every 2 days.

[0049] (4) Transfer the material after the first fermentation into the storage bin of the heated kang system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com