Mold regulator of powder molding machine

The technology of an adjusting device and a press molding machine, which is applied in the mechanical field, can solve the problems of unilateral force on the core rod sleeve, affecting the stability of use, and cumbersome adjustment, and achieves balanced force, high adjustment stability, and simple locking process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

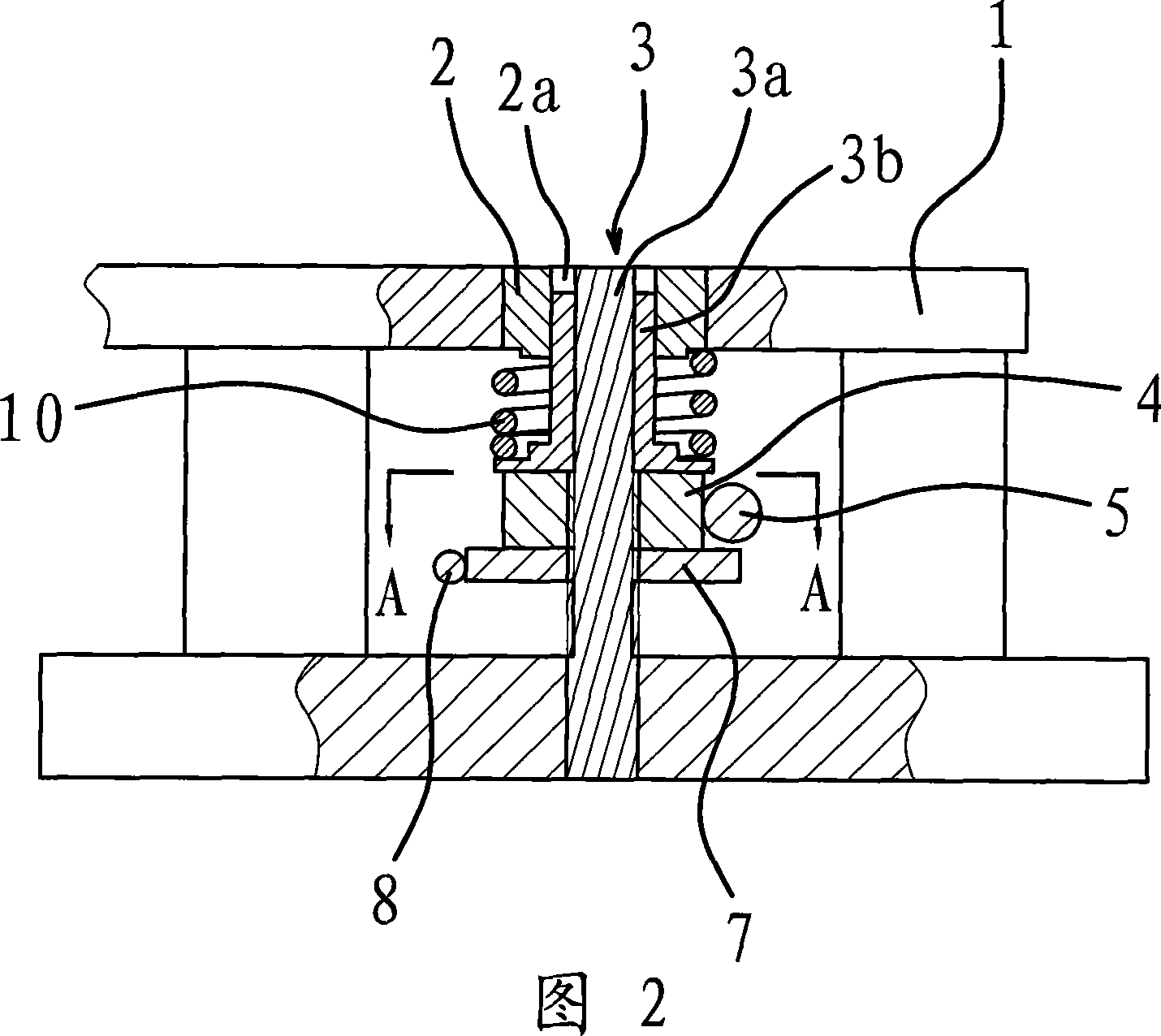

[0030] As shown in FIG. 1 , the powder compression molding machine includes a mold on a frame and a stamping head 11 above the mold, and the mold adjustment device of the powder compression molding machine is arranged at the mold.

[0031] The mold of the powder compression molding machine is composed of a mold base 1, a storage body 2 and a stripping body 3, etc. Wherein, the material storage body 2 is fixedly connected to the mold base 1, and the material storage body 2 is provided with a material hole 2a passing through it up and down.

[0032] The stripping body 3 is composed of a core rod 3a and a core rod sleeve 3b, the core rod 3a is cylindrical, and the outer diameter of the core rod 3a is smaller than the diameter of the material hole 2a. The core rod sleeve 3b is cylindrical, the outer diameter of the core rod sleeve 3b is slightly smaller than the diameter of the material hole 2a, and the inner diameter of the core rod sleeve 3b is slightly larger than the outer dia...

Embodiment 2

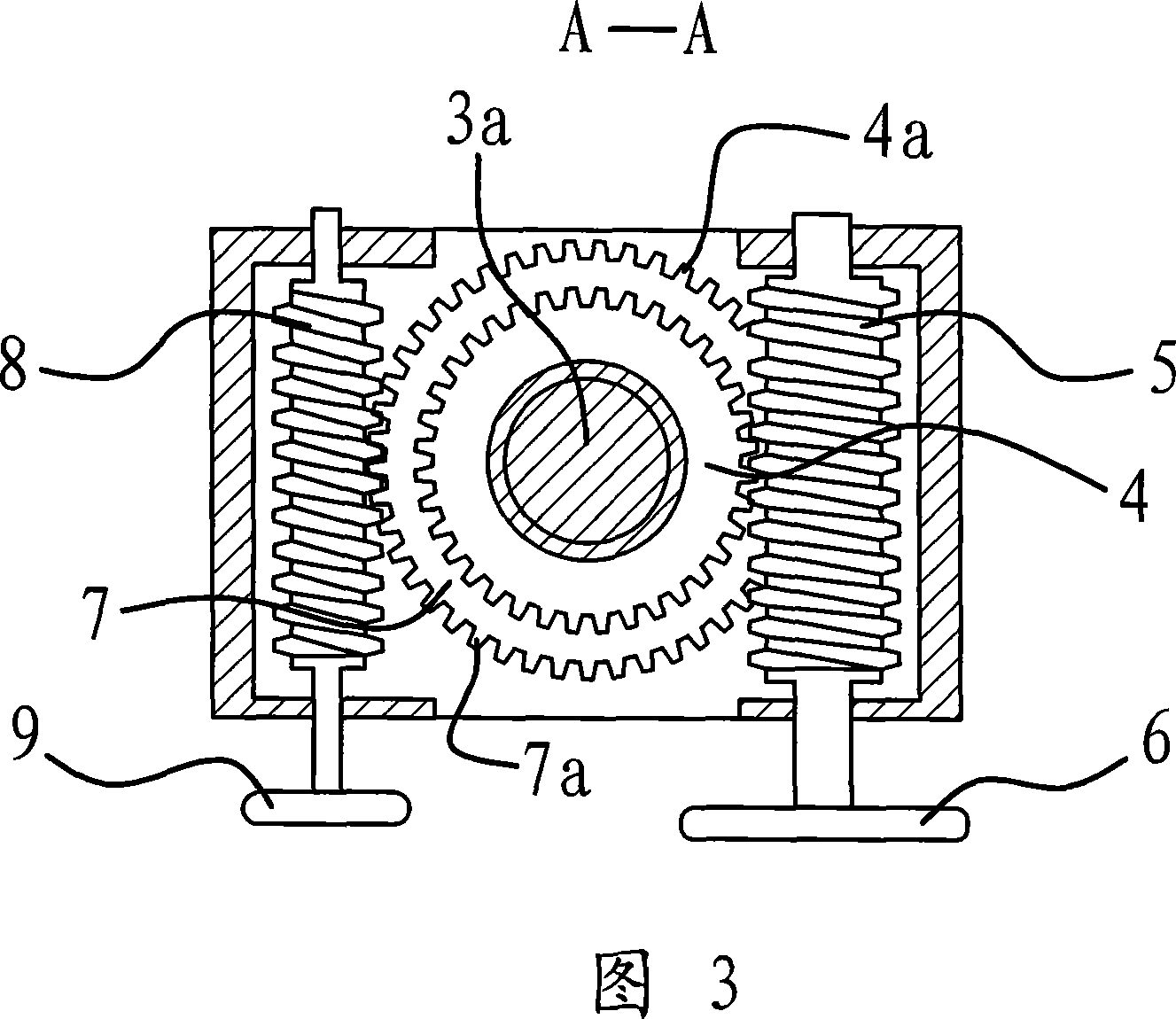

[0042] The structure and principle of this embodiment are basically the same as those in Embodiment 1, except that the rotating structure is a prismatic structure on the outside of the regulating body 4, as shown in Fig. 4 and Fig. 5 . When the adjusting body 4 needs to be rotated, a tool such as a wrench is connected to the prismatic place of the adjusting body 4, and the wrench can be pulled to drive the adjusting body 4 to rotate.

[0043] Meanwhile, in this embodiment, the locking structure is a prismatic structure outside the locking body 7 , as shown in FIG. 4 and FIG. 5 . When the locking body 7 needs to be rotated, a tool such as a wrench is connected to the prismatic place of the locking body 7, and the locking body 7 can be driven to rotate by pulling the wrench.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com