Fermented milk and process for producing the same

A manufacturing method and technology of fermented milk, applied in the direction of dairy products, milk preparations, applications, etc., to achieve the effect of not rough appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (Fermentation process of yogurt mixture containing dairy products and milk protein)

[0050] 1725g of skimmed powdered milk, 525g of milk protein concentrate (hereinafter referred to as "MPC"), and 750g of sugar were stirred and dissolved with 10740g of room temperature water. Then, the solution was heated to 50° C. while stirring, and after reaching the temperature, 810 g of unsalted butter was added. After dissolving, the temperature was raised to 70°C, and the solution was put into a homogenizer. After homogenization, heat up to 95°C and cool to 43°C after reaching the temperature.

[0051] Next, 3% by weight of mixed primers of Lactobacillus bulgaricus and Streptococcus thermophilus isolated from "Meiji Bulgaria yoghurt" manufactured by Meiji Dairy Co., Ltd. was inoculated and stirred for 5 minutes.

[0052] The yoghurt mixture is fermented at around 43° C., and the fermentation is terminated when the pH is below 4.7.

[0053] The solid content concentration of t...

Embodiment 2

[0075] Adopt the TRIANGLE filter (trade name, manufactured by Arai Iron Works Co., Ltd.) with a plurality of fine openings formed by a plurality of slits with a slit width of 15 μm formed in the filter member, in which, the same operation as in Example 1, The obtained fermented milk curd (that is, yogurt mixture with a solid content concentration of 24.2%, a protein concentration of 7.1%, a lipid of 4.7%, a sugar of 5.0%, and no stabilizer added) flowed through a plurality of slits with a slit width of 15 μm. After slot extrusion and crushing of the fermented milk curd, it was performed in the same manner as in Example 1, and rapidly cooled to about 5° C. using a heat exchanger such as a tubular cooler. Thereafter, it was put into a predetermined mold, and cooled (3 to 5°C, 12 hours) in a refrigerator to obtain soft yoghurt of fermented milk of the present invention.

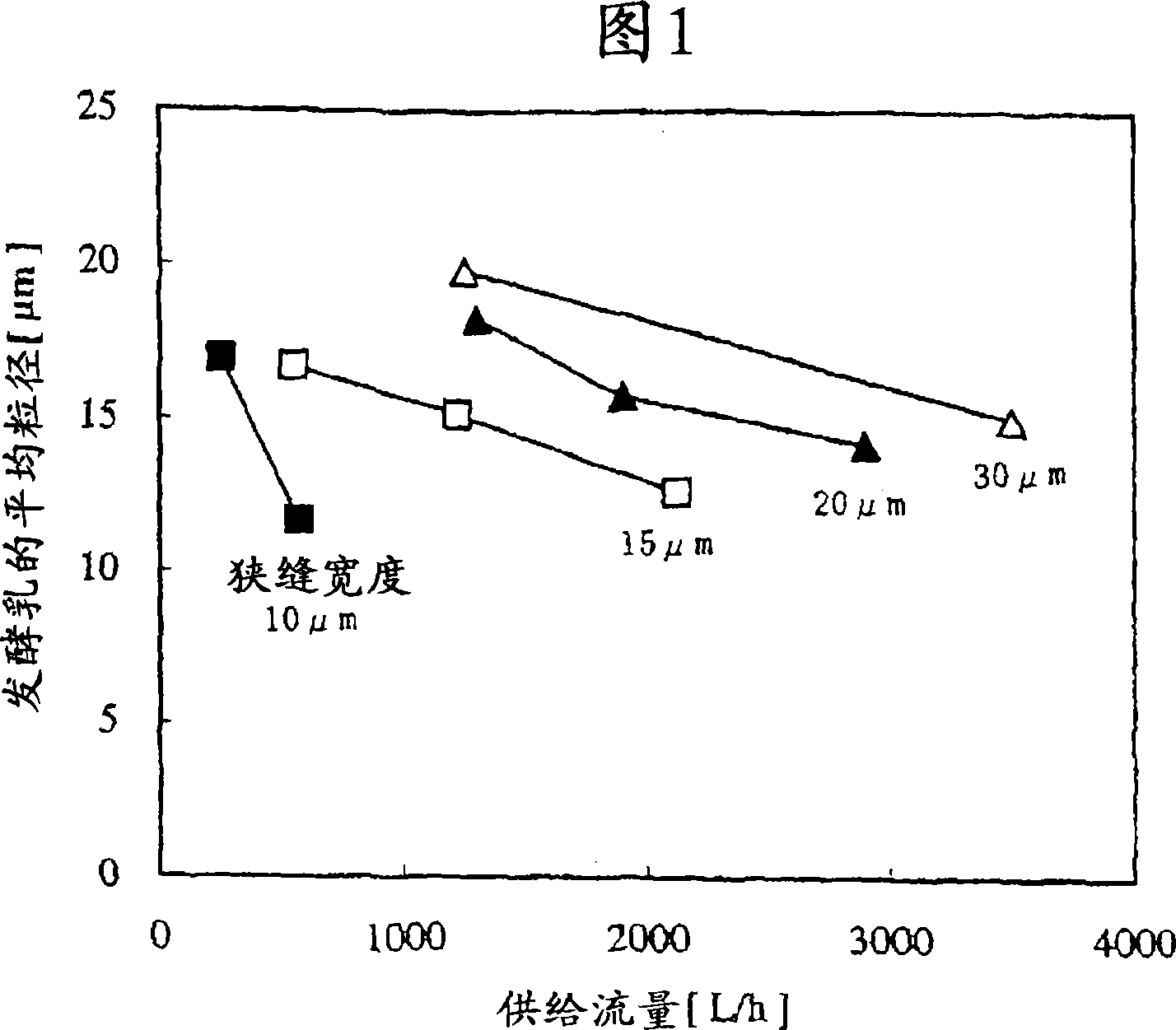

[0076] In this Example 2, the size of the openings (slits with a slit width of 15 μm) of a Triangul filter (t...

Embodiment 3

[0085] Using a triangular filter (trade name, manufactured by Arai Iron Works Co., Ltd.) with a plurality of slits having a slit width of 20 μm to form a plurality of fine openings on the filter member, it was obtained in the same manner as in Example 1. The fermented milk curd (that is, yogurt mixture with solid content concentration 24.2%, protein concentration 7.1%, lipid 4.7%, sugar 5.0%, no stabilizer added) flows through a plurality of slits with a slit width of 20 μm After extruding and crushing the fermented milk curd, it is performed in the same manner as in Example 1, and is rapidly cooled to about 5° C. using a heat exchanger such as a tubular cooler. Thereafter, it was put into a predetermined mold, and cooled (3 to 5°C, 12 hours) in a refrigerator to obtain soft yoghurt of fermented milk of the present invention.

[0086] In Example 3, the size of the openings (slits with a slit width of 20 μm) of a Triangul filter (trade name) in which a plurality of fine opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com