Tooth abrading device

A wear test, dental technology, applied in dentistry, wear resistance testing, medical science, etc., can solve the problems of complex design, high production cost, inconvenient operation and control, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

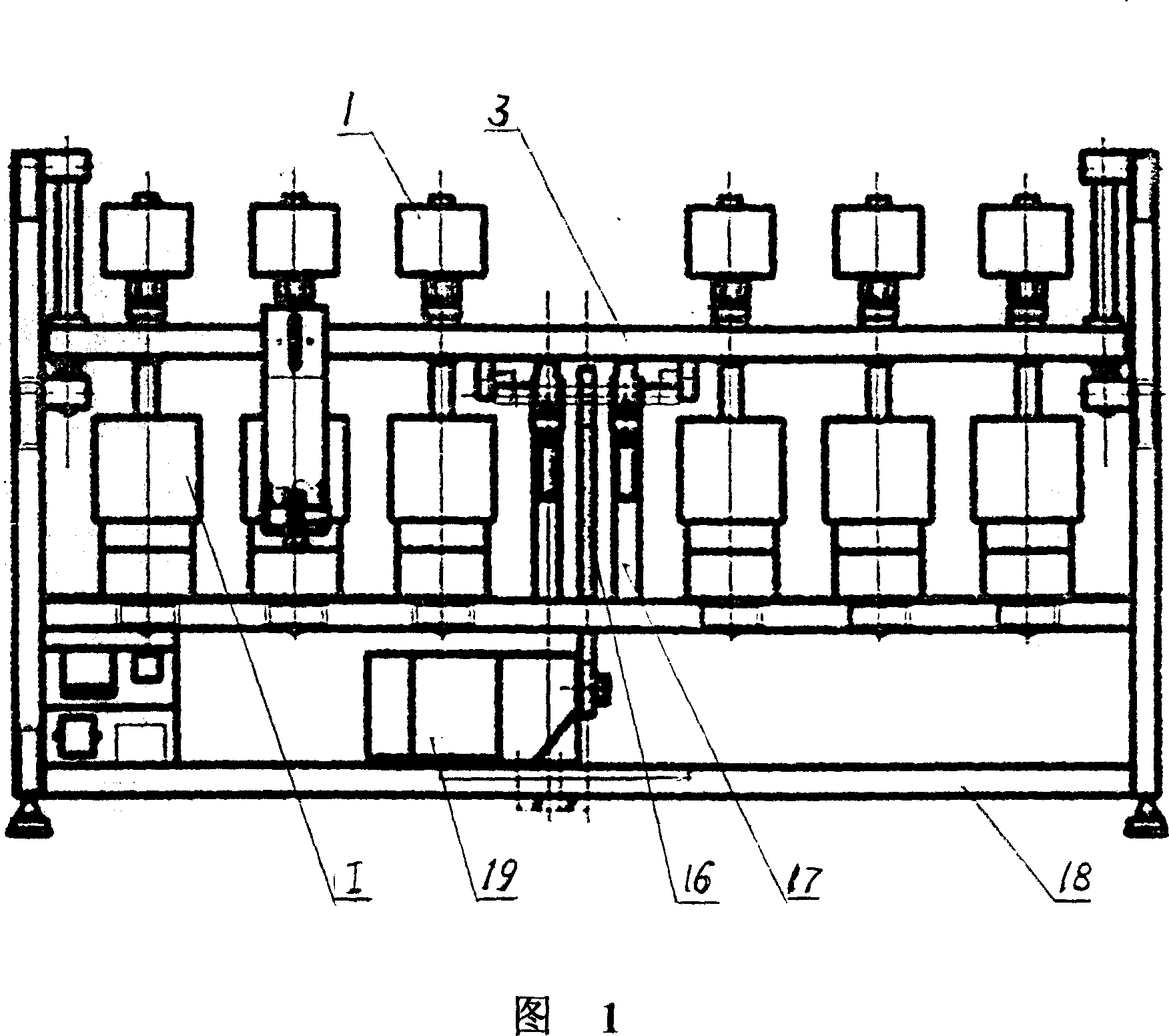

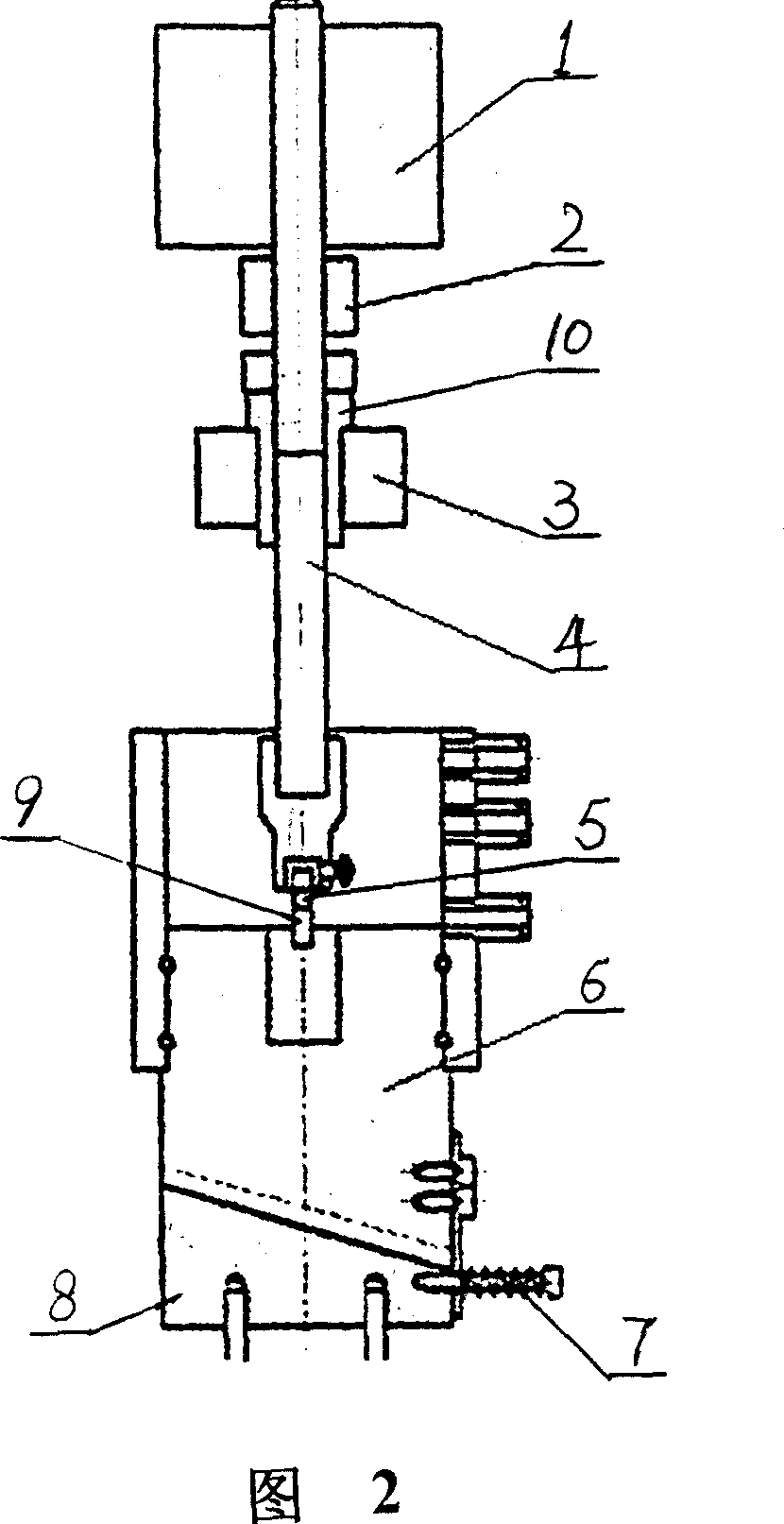

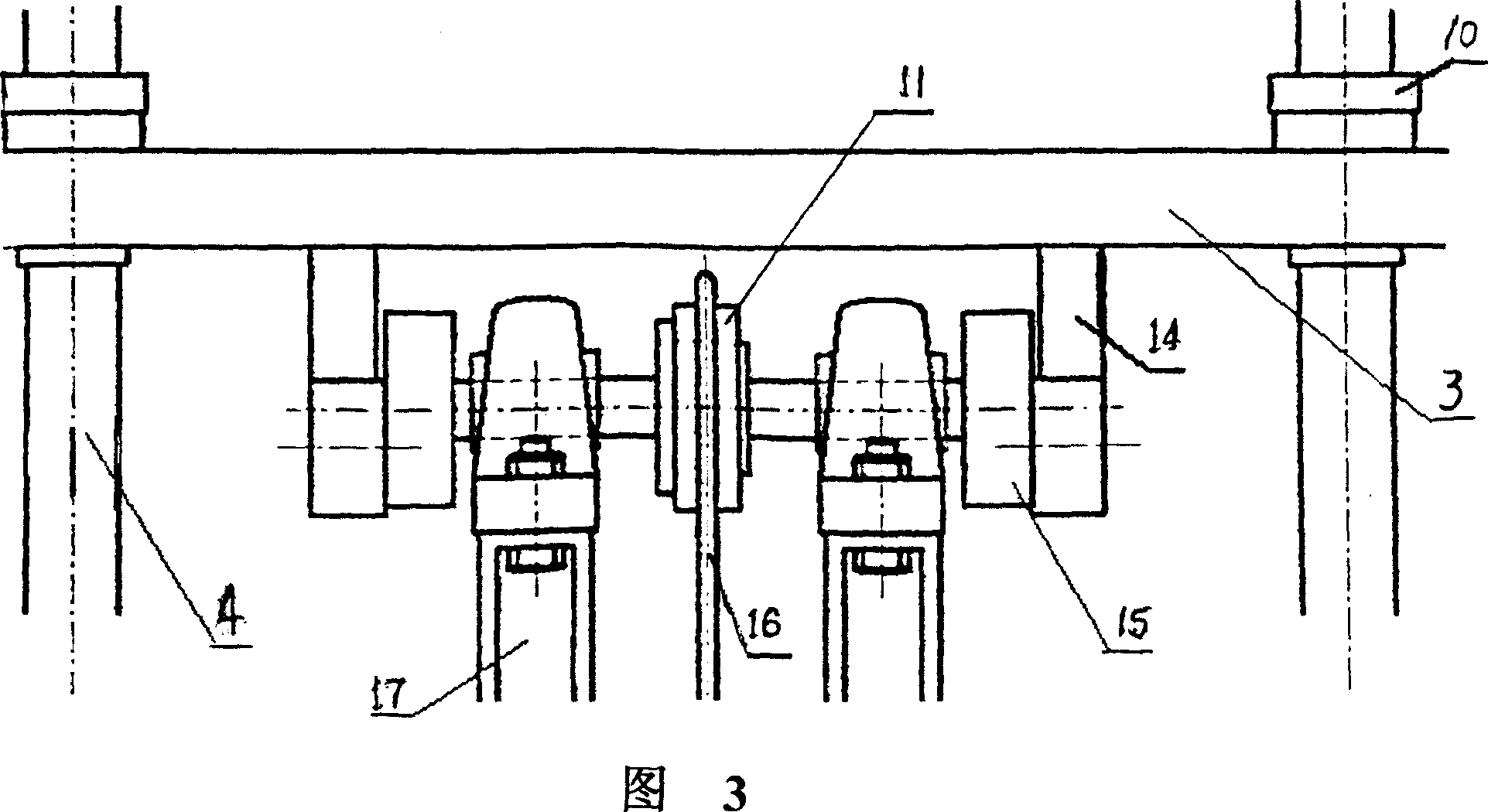

[0010] Referring to the accompanying drawings, the tooth wear testing machine of the present invention includes two major parts, a mechanical action device and an electrical device. The mechanical action device is mainly composed of frame table 18, crossbeam 3, cam transmission mechanism and six groups of tooth wear test units 1 arranged in parallel on the frame table 18. The crossbeam 3 reciprocates up and down under the action of the cam drive mechanism through the cam drive frame 17 and the guide rods arranged on both sides of the frame platform 18 frames. In order to achieve the reciprocating action of the crossbeam, the present invention considers the use of a cam transmission mechanism, which is located in the middle of the frame table 18, as shown in Figure 3, it has a drive frame 17 and is connected to the main shaft of the motor 19 through the transmission chain 16. The sprocket 11 is respectively equipped with a pair of cam 15 and jack block 14 for jacking up the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com