City-rail steel spring floating slab rail bed railroad switch construction method

A construction method and floating slab technology, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of high vibration and noise, lack of ideals, and high maintenance costs, so as to reduce urban noise pollution, improve the environment, reduce Effects of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

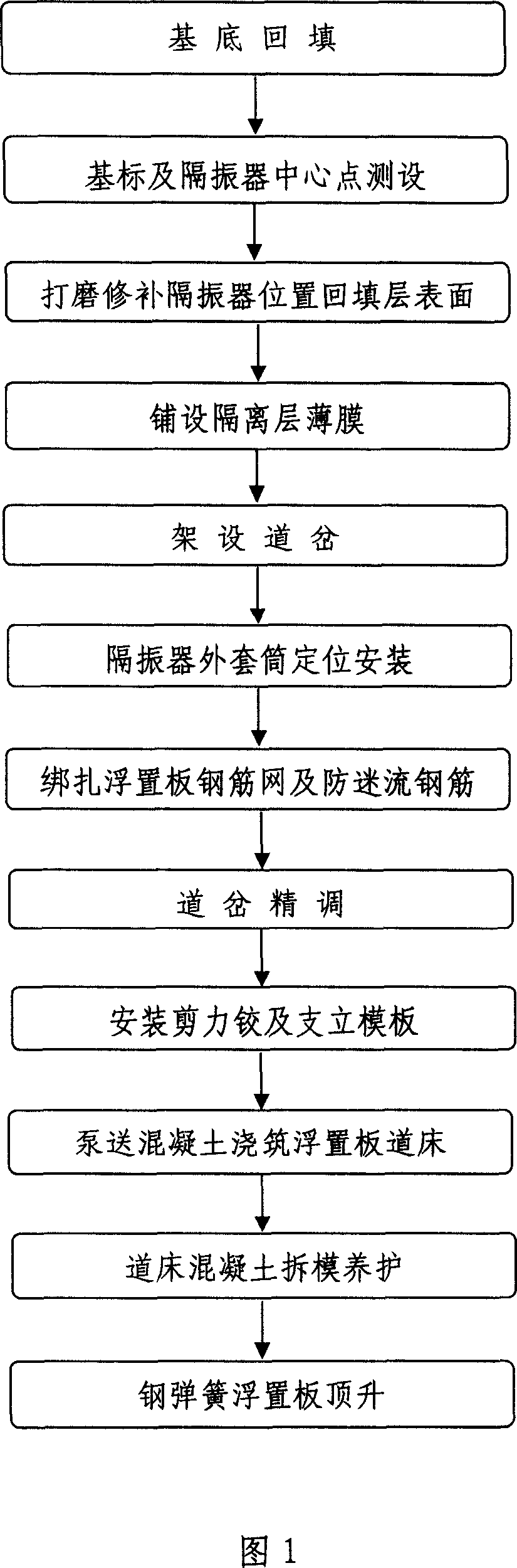

[0010] Taking urban subway construction as an example, referring to the accompanying drawings, the specific construction methods are as follows:

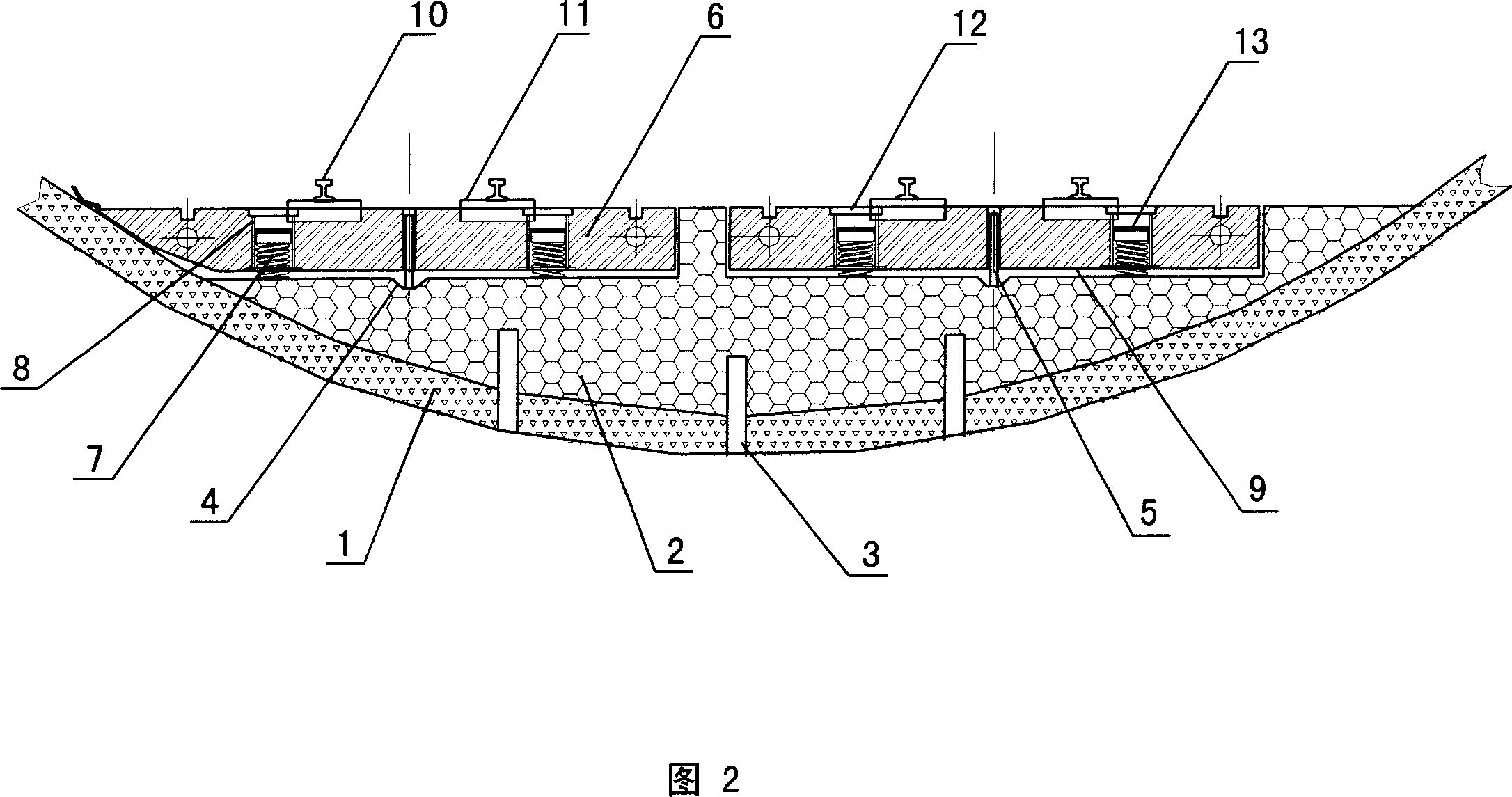

[0011] a. Substrate backfill

[0012] a.1 Carry out a comprehensive chiseling treatment on the tunnel structure base (1), clean the tunnel floor, install expansion anchor bolts (3) at the bottom of the tunnel side wall, and bind them firmly with the reinforcement mesh of the backfill layer (2),

[0013] a.2 Lay a single layer of steel mesh on the concrete of the base (1), and make a downward bending treatment at the place where it meets the ditch,

[0014] a.3 The bottom plate is provided with a semi-circular water ditch (4). The formwork is made of PVC pipe, which is divided into two along the radial direction.

[0015] a.4 Arrange backfilling concrete surface elevation piles according to the vertical and horizontal spacing not greater than 3 meters, pour concrete,

[0016] b. Measurement and design of base standard and center po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com