On-line calibration and checking method for current inductor transformation ratio and angle difference

A technology for current transformers and calibration methods, which is applied in the direction of measuring electrical variables, instruments, and measuring devices, and can solve problems such as inability to drift calibration and calibration, and inability to obtain high-precision, stable and reliable measurement results, etc., to achieve easy access , Realize the effects of online calibration and verification, high accuracy and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

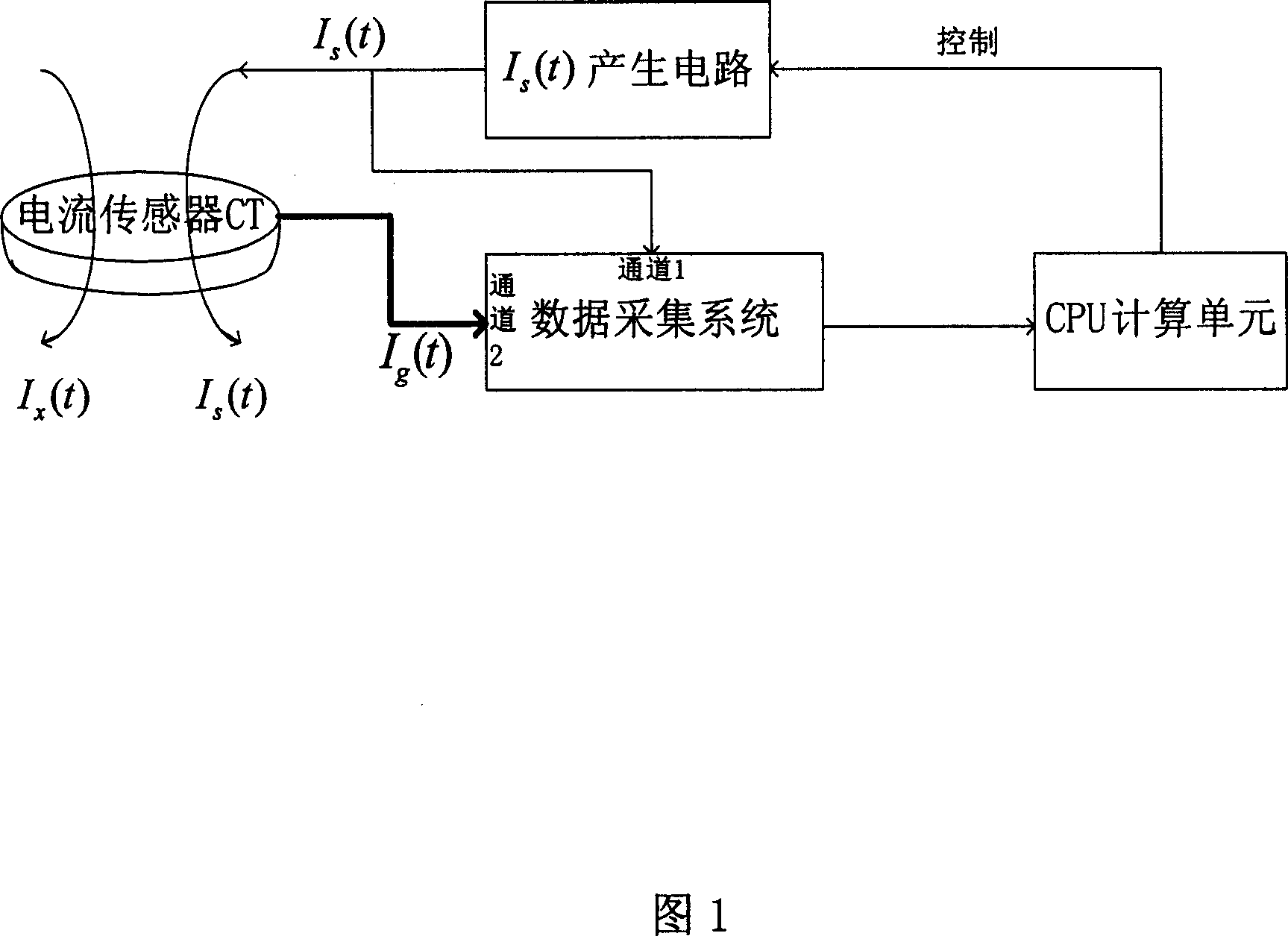

[0022] Figure 1 is a schematic structural diagram of the insulation on-line monitoring system of the present invention. The monitoring working method of the insulation on-line monitoring system, the CPU calculation unit controls the measurement current I s (t) generation, I s (t) and I x (t) pass through the current transformer together to get the mixed current I g (t), I g (t)=a 1 I x (t)+a 2 I S (t), the I g (t) and I s (t) sent to the channel 1 and channel 2 of the data acquisition system at the same time, and sent to the CPU calculation unit after digitization for independent element analysis and signal separation, and I can be obtained s (t) estimated signal I s '(t). The mixing coefficient a calculated from 1 , a 2 It is convenient to calculate and obtain the current transformer characteristic coefficients such as the transformation ratio and angle difference of the current transformer in the actual working environment, and accurately determine and measure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com