Method of preparing infusible hollow heteromorphic foam aluminum alloy by secondary foam

A foamed aluminum alloy and aluminum alloy technology, which is applied in the field of secondary foaming to prepare insoluble hollow special-shaped foamed aluminum alloys, can solve the problems that foamed aluminum special-shaped parts have not been reported, and achieve low cost, uniform pore structure, and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Heat the aluminum alloy to melt, add calcium equivalent to 0.5% to 5% of the weight of the aluminum alloy to the molten aluminum alloy, stir evenly for 20 to 800 seconds to increase viscosity; then add calcium equivalent to the weight of the aluminum alloy Stir 0.5% to 5% titanium hydride at a speed of 800 to 5000r / m for 20 to 400 seconds, so that the titanium hydride is evenly mixed in the melt, and then put out the stirring blade;

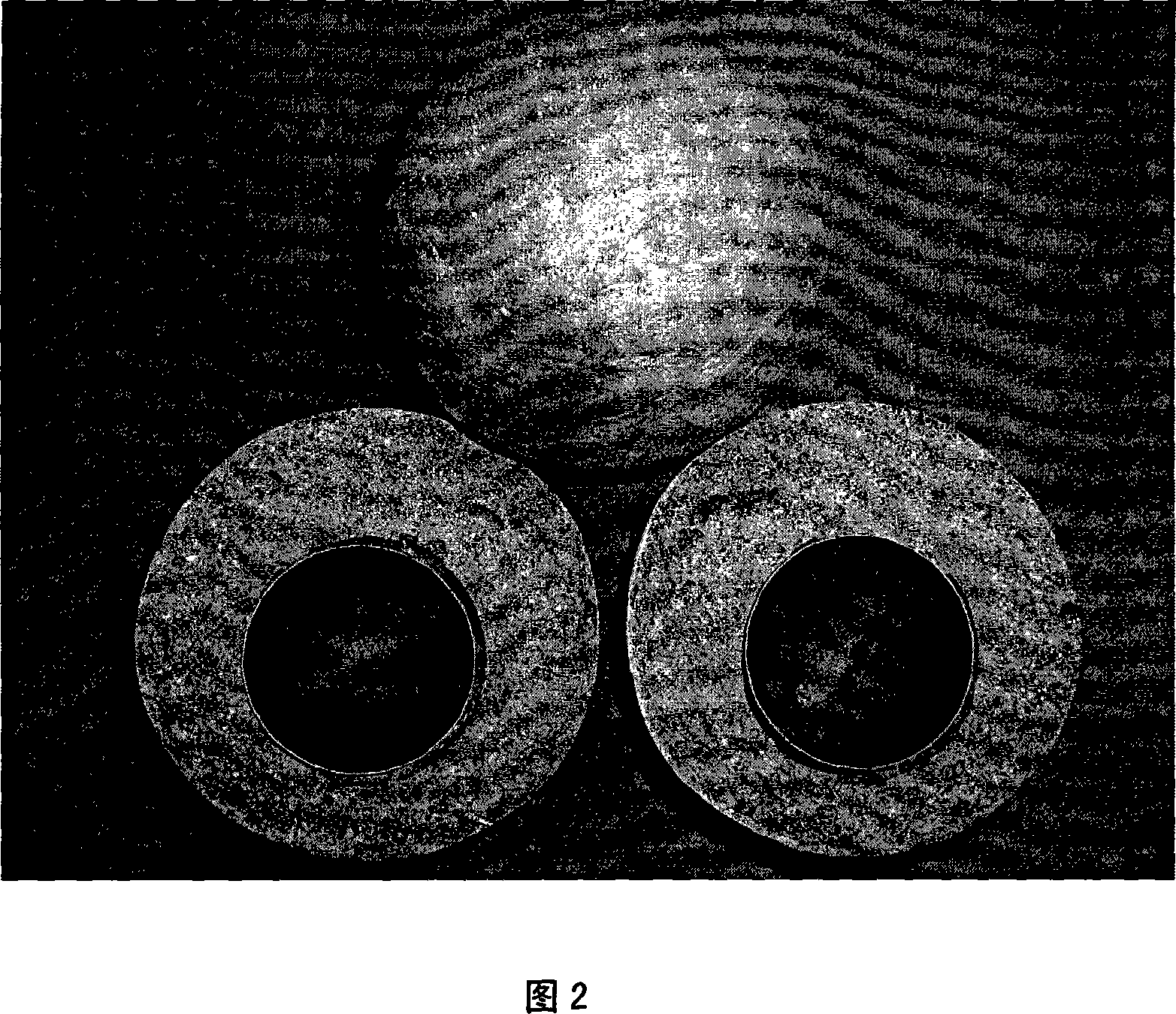

[0020] The second step: quickly place the non-meltable ball in the foamed aluminum alloy melt and ensure that it is completely immersed in the melt to form a closed body. Rapid cooling of the primary foamed aluminum alloy melt with built-in non-melting hollow spheres to obtain a secondary foamed aluminum alloy prefabricated part with a porosity lower than 65.5%;

[0021] Step 3: Heat the secondary foamed aluminum alloy preform with built-in non-melting balls to a temperature of 300°C to 650°C for 10 to 50 minutes, so that the alumi...

Embodiment 2

[0024] Step 1: Heat the aluminum alloy to melt, add calcium equivalent to 0.5% of the weight of the aluminum alloy to the molten aluminum alloy, stir evenly for 20 seconds to increase viscosity; then add 0.5% of the weight of the aluminum alloy to titanium hydride , stirring at a speed of 800r / m for 200 seconds, so that the titanium hydride is evenly mixed in the melt, and then put out the stirring paddle;

[0025] The second step: quickly place the non-meltable ball in the foamed aluminum alloy melt and ensure that it is completely immersed in the melt to form a closed body. Rapid cooling of the primary foamed aluminum alloy melt with built-in non-melting hollow spheres to obtain a secondary foamed aluminum alloy prefabricated part with a porosity lower than 65.5%;

[0026] Step 3: Heat the secondary foamed aluminum alloy preform with built-in non-melting balls to a temperature of 300°C for 10 minutes so that the aluminum alloy preform can avoid the phenomenon of uneven pore ...

Embodiment 3

[0029] Step 1: Heat the aluminum alloy to melt, add calcium equivalent to 5% of the weight of the aluminum alloy to the molten aluminum alloy, stir evenly for 800 seconds to increase viscosity; then add titanium hydride equivalent to 5% of the weight of the aluminum alloy , stirring at a speed of 5000r / m for 400 seconds, so that the titanium hydride is evenly mixed in the melt, and then put out the stirring paddle;

[0030] The second step: quickly place the non-meltable ball in the foamed aluminum alloy melt and ensure that it is completely immersed in the melt to form a closed body. Rapid cooling of the primary foamed aluminum alloy melt with built-in non-melting hollow spheres to obtain a secondary foamed aluminum alloy prefabricated part with a porosity lower than 65.5%;

[0031] Step 3: Heat the above-mentioned secondary foamed aluminum alloy preform with built-in non-melting balls to a temperature of 650°C for 50 minutes so that the aluminum alloy preform can avoid the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com