Semiconductor rubber member and developing roller composed of semiconductor rubber member

A technology of rubber parts and semiconductors, which is applied in the direction of electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, electric recording technique, etc., to achieve the effect of suppressing resistance value and preventing the decrease of printing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

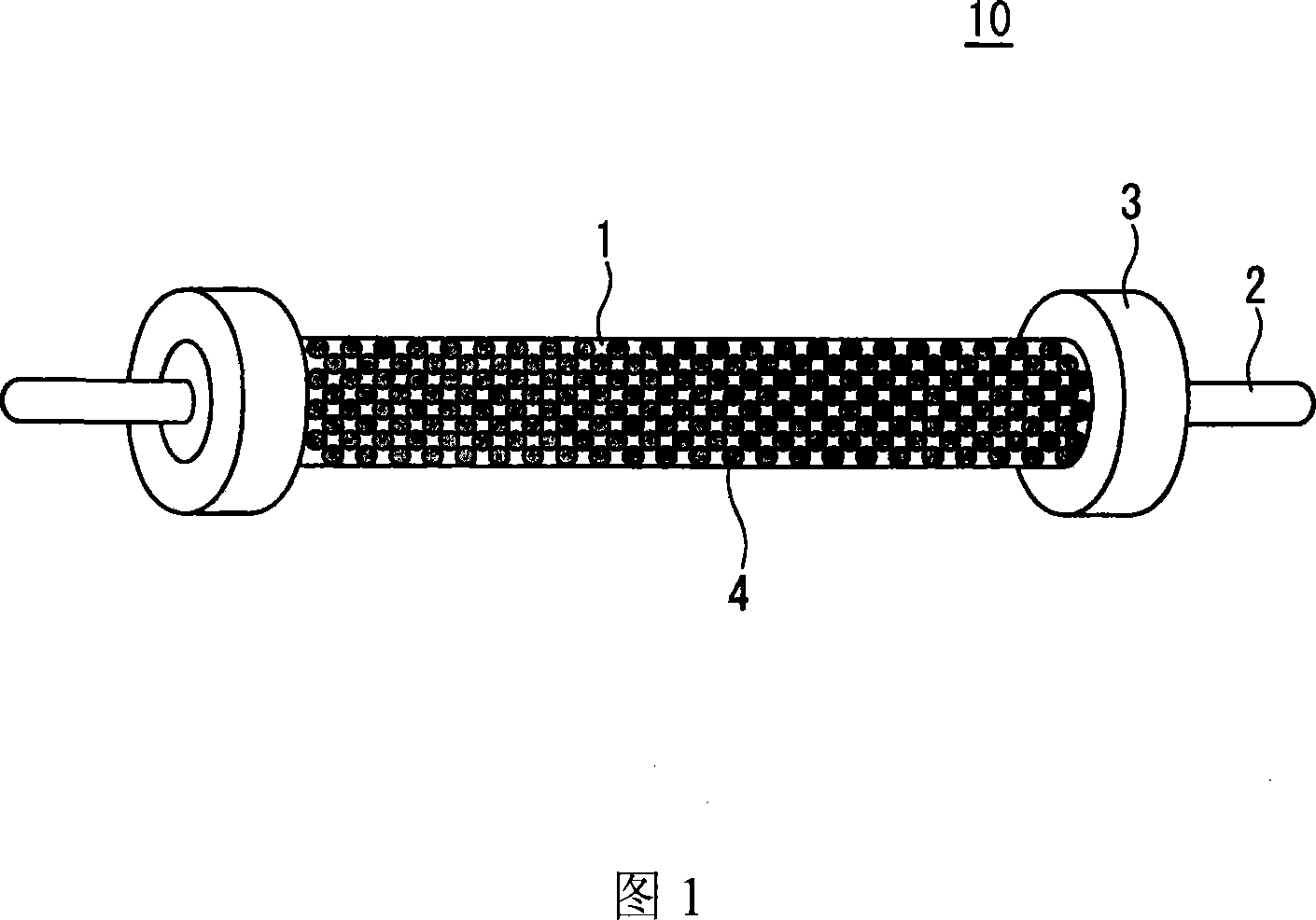

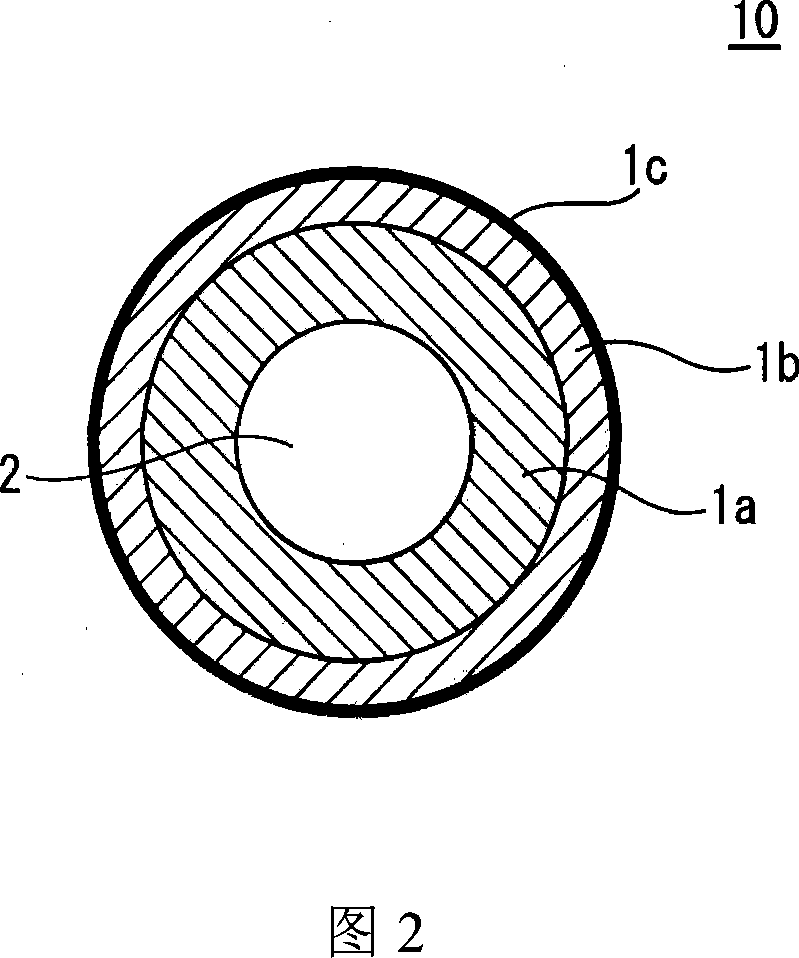

[0168] The semiconductor rubber roller 10 of the present invention is described as a specific embodiment of the semiconductor rubber member of the present invention as follows:

[0169] As shown in FIG. 1, a semiconductor rubber roller 10 serving as a developing roller has: a cylindrical toner conveying portion 1 having a thickness of 0.5 mm to 20 mm, preferably 1 to 15 mm, and more preferably 5 to 15 mm; A cylindrical metal shaft 2 inserted into the hollow portion of the semiconductor rubber roller 10; and a pair of annular sealing portions 3 preventing leakage of the toner 4. The toner conveying portion 1 and the metal shaft 2 are bonded together with a conductive adhesive. The reason why the thickness of the toner conveying portion 1 is set to 0.5 mm to 20 mm is as follows: if the thickness of the toner conveying portion 1 is less than 0.5 mm, it is difficult to obtain an appropriate gap spacing. If the thickness of the toner conveying portion 1 is greater than 20 mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com