Liquid separation membrane component with ultrasonic device

A technology of liquid separation and membrane modules, applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problems of unsatisfactory treatment effect and low treatment efficiency, achieve short action time, significant effect, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

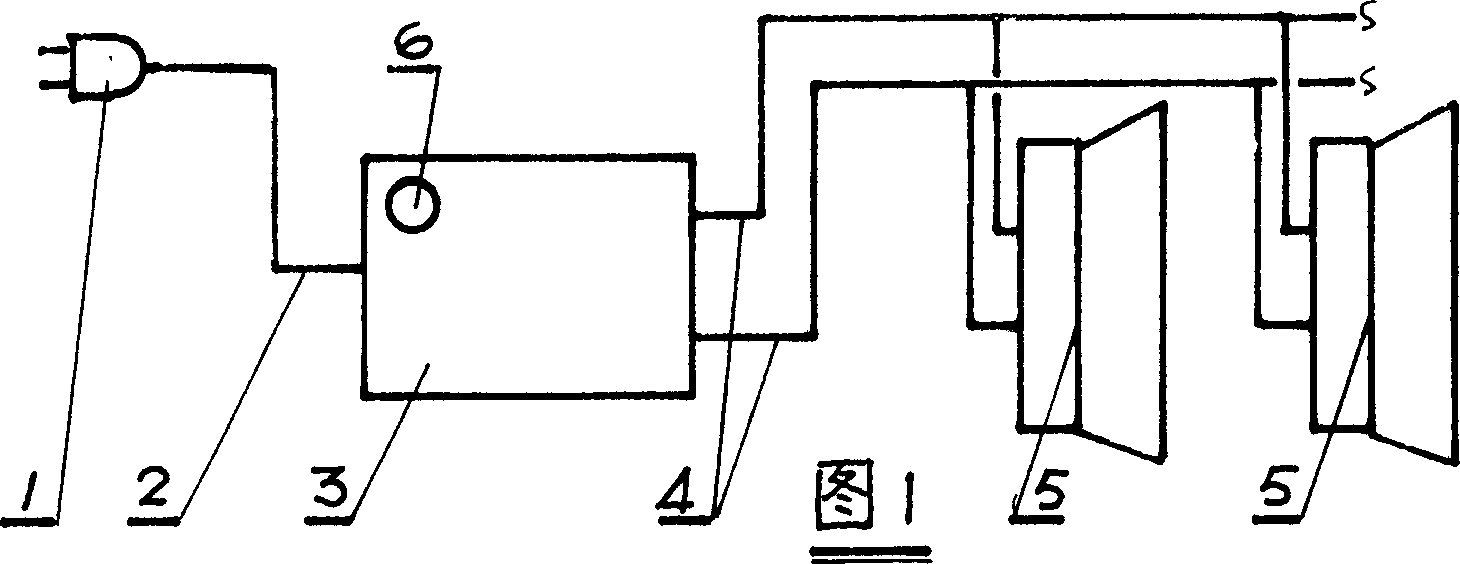

[0019] Among Fig. 1, ultrasonic generator 3 is connected with power supply by power line 2, power plug 1, then is connected with transducer 5 by wire 4, and ultrasonic generator 3 is provided with switch regulator 6 and is used for the operation and shutdown of ultrasonic device And control the power of ultrasonic waves.

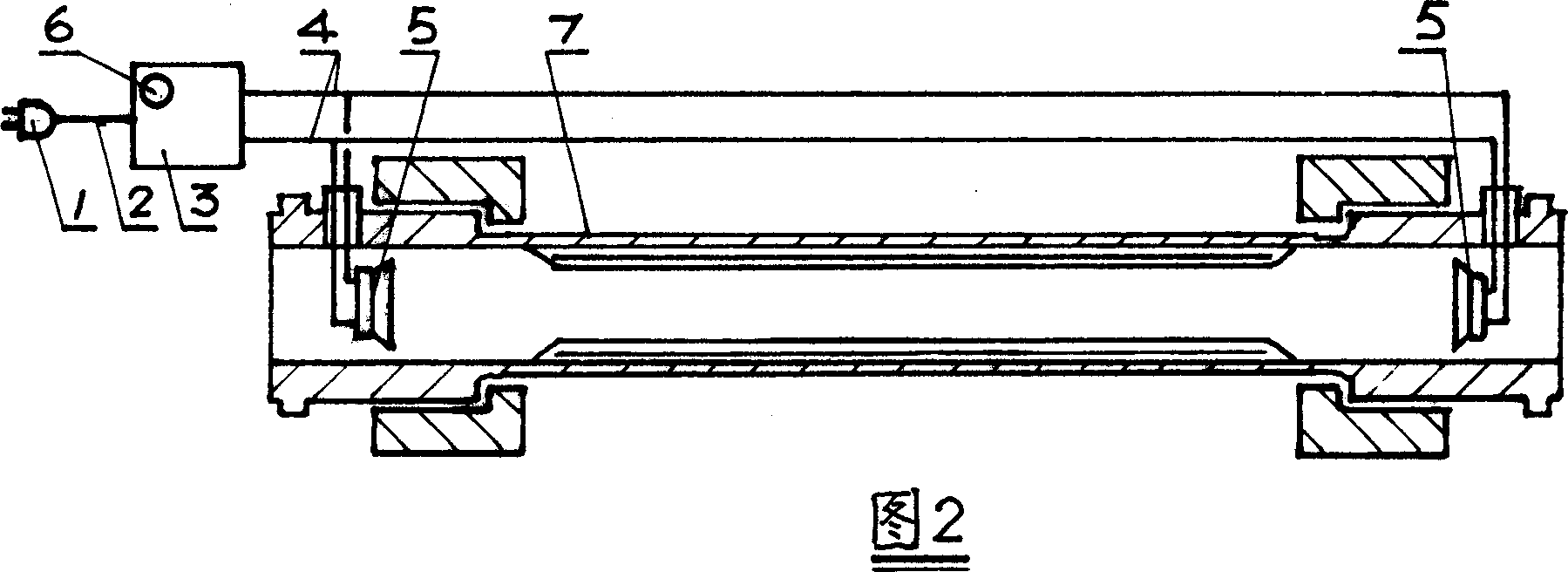

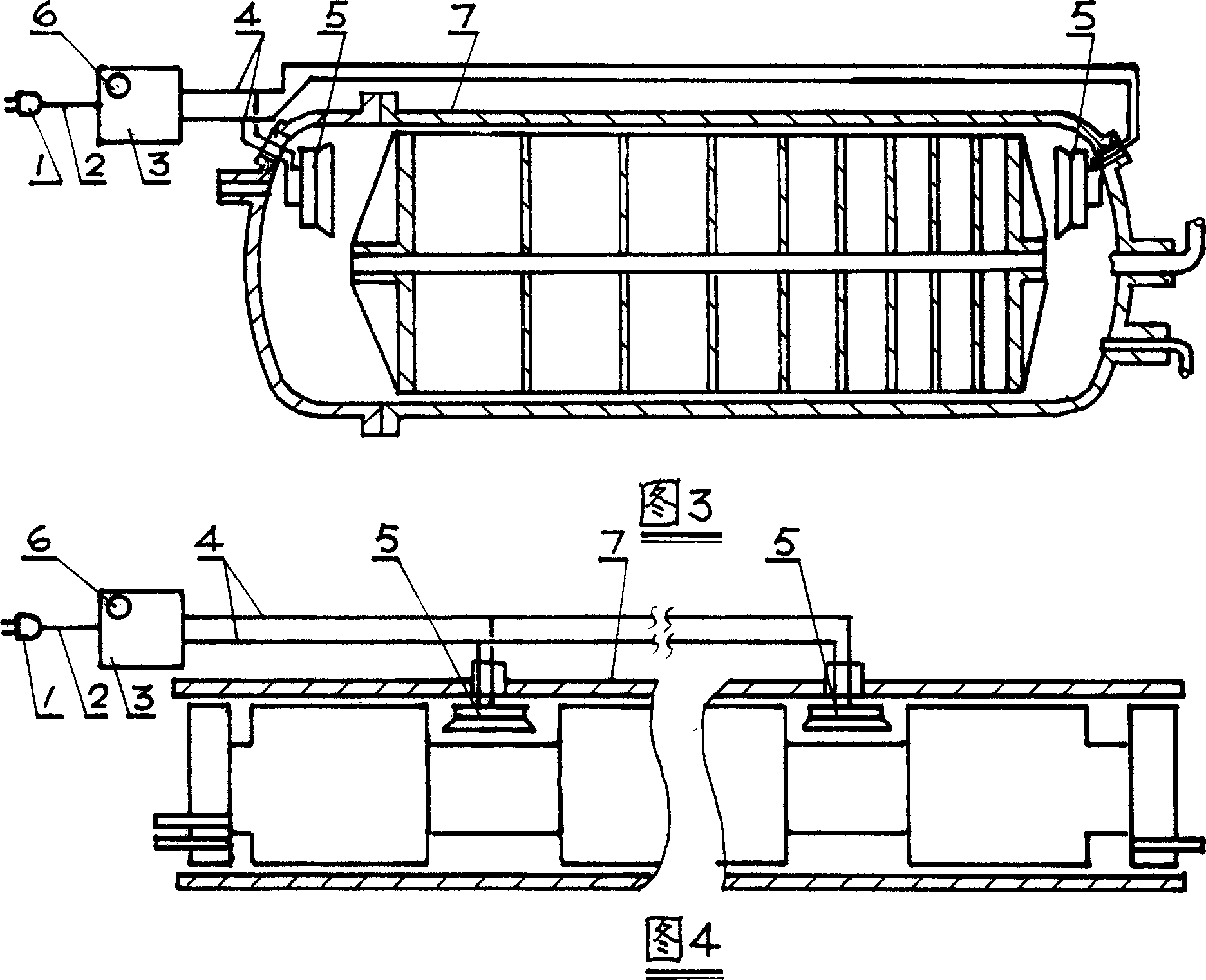

[0020] In Fig. 2, Fig. 3 and Fig. 4, it is shown that the transducer 5 of the ultrasonic device is installed in the liquid cavity of the membrane module 7, and the purpose of treating membrane fouling is achieved by utilizing the good transmission conditions of the liquid medium for ultrasonic waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com