Transfer press machine

A multi-station press and multi-station technology, applied to presses, positioning devices, manufacturing tools, etc., can solve problems such as difficult stamping processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

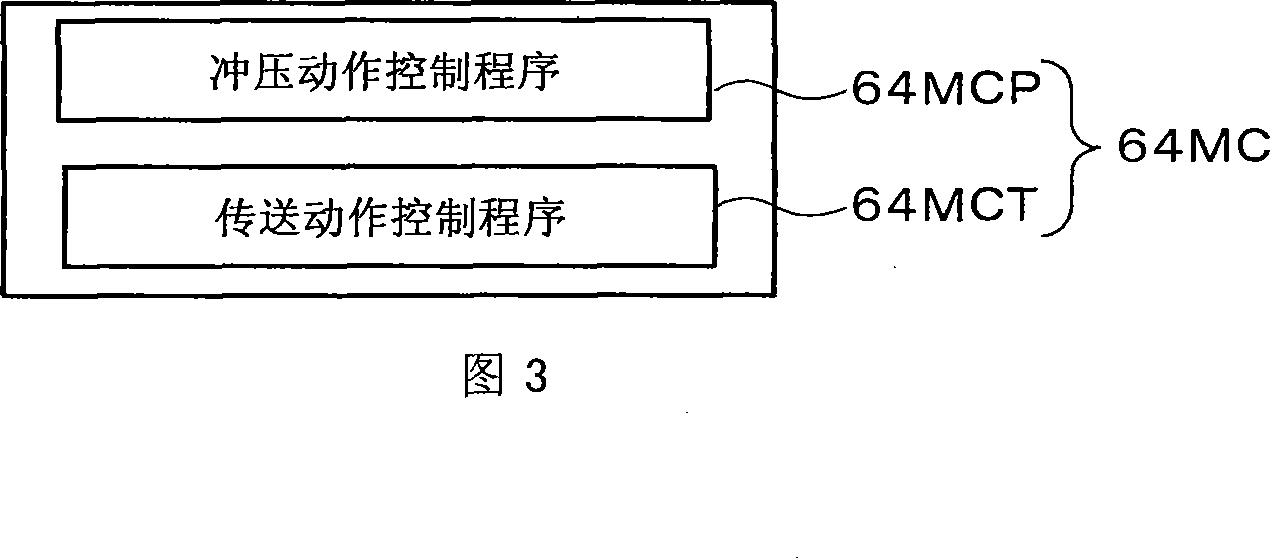

[0071] The multi-station press (10, 40) is provided with an interference inspection device, as shown in Fig. The motion control unit (61, 64), the generation and output unit (61, 64) of virtual synchronous timing information, and the judging unit (61, 64) of whether virtual interference occurs, after performing three-dimensional shape data conversion to have the same The situation in the actual space is the same, and the relative positional relationship is expanded and arranged. The stamping-side data-based constituent elements and the conveying-side data-based constituent elements perform a virtual multi-station stamping cycle, and it is possible to judge whether the two are The virtual interference is generated so that the multi-station press cycle in the actual space is not actually executed, but the interference can be checked during the progress of the multi-station press cycle in the virtual space.

[0072] In addition, in the first embodiment, the first imaginary interf...

no. 2 Embodiment approach

[0162] The basic configuration and functions of this second embodiment are the same as those of the first embodiment (Figs. 1-11), but instead of the first imaginary interference confirmation object including the first manipulator path shape box generation and arrangement control unit (61, 64), The object extracting unit is provided with a second imaginary interference confirmation object extracting unit containing the second manipulator path shape box generation configuration control unit (61, 64), which can more quickly determine whether there is imaginary interference in the imaginary material 200D .

[0163] That is, the second imaginary interference confirmation object extraction unit (61, 64) has the following functions: make the digitized upper die 16D (digitized slider 15D) descend in imaginary space (ST1527 in FIG. 14 ) to the imaginary bottom dead center In the case of , the interference between the digitized upper mold 16D and the digitized lower mold 18D and the di...

no. 3 Embodiment approach

[0176] The basic structure and function of this transfer press (10, 40) are the same as those of the first embodiment (Figs. 1-5), and as shown in Figs. 64 IPT, the hypothetical interference generation inspection device shown in Figure 20, and the SPM automatic determination device shown in Figures 18 and 19 (including the optimization of the clamping and loosening action optimization units (61, 64) and the lifting and lowering action optimization units The action determination control unit (61, 64)) can automatically determine the optimal action, that is, the allowable SPMclp·ucl for the clamping and loosening actions preset on the side of the clamping and loosening action optimization unit and the lifting, Either one of the permissible SPM1ft·dwn for ascending and descending movements preset by the descending motion optimization unit, and the allowable SPM of the smaller value is set as the SPM (Stroke Per Minute) of the press machine 10 .

[0177] Here, as shown in Figures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com