Rotary electromagnetic type uniform tidal current controller

A power flow control and electromagnetic technology, applied in circuit devices, electrical components, AC network circuits, etc., can solve the problems of reducing device reliability, increasing device cost, and low device overload capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

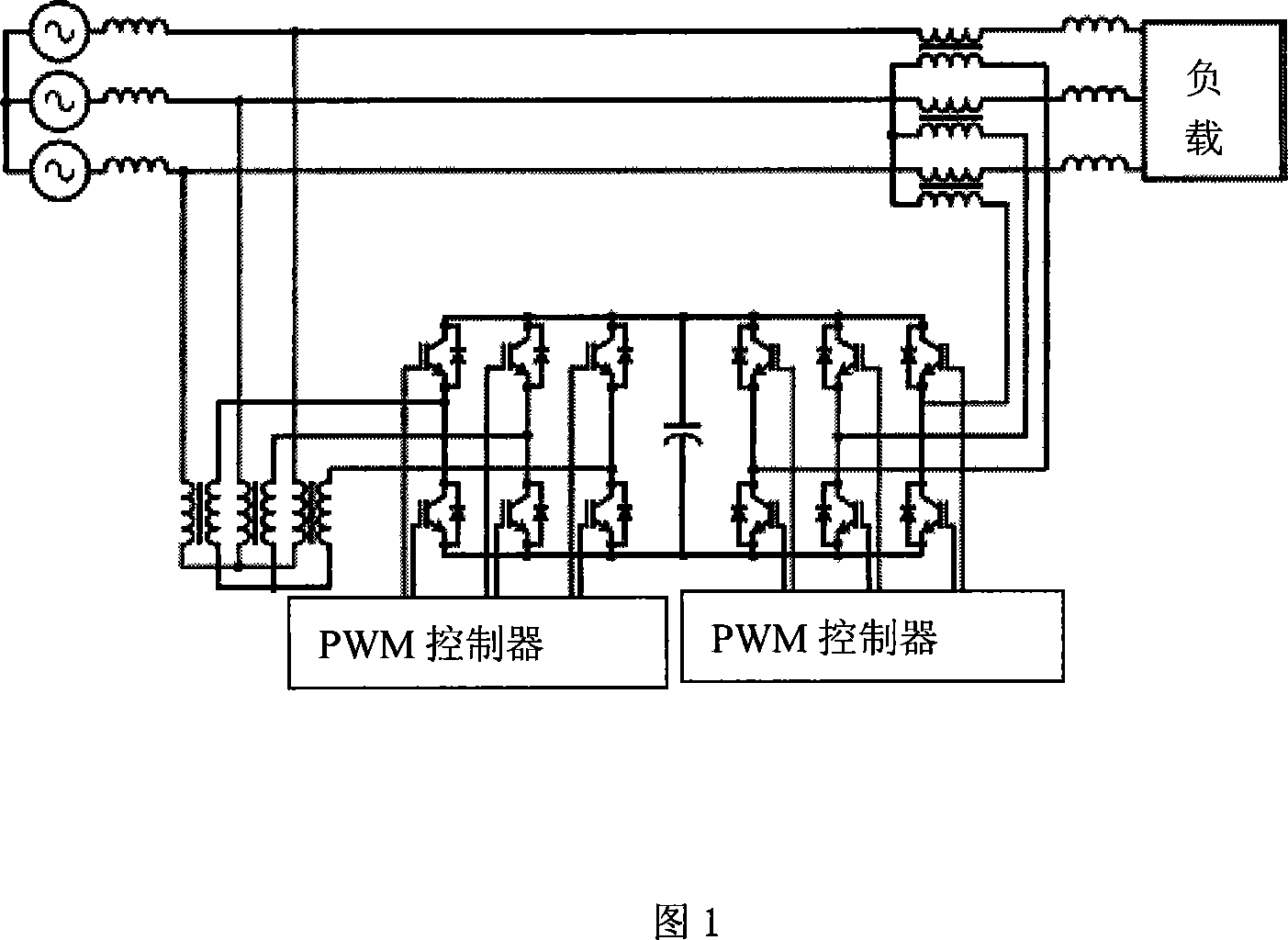

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific implementation mode 1: This implementation mode will be specifically described below with reference to FIG. 2 . This embodiment consists of a wound rotor induction motor 1, an AC excitation power supply 2, an AC chopper 3 and a transformer 4. There are two sets of three-phase symmetrical windings on the stator of the wound rotor induction motor 1, and one set is a parallel winding. 1-1, the other set is the series compensation winding 1-2, one end of the series compensation winding 1-2 is connected to the input side of the AC chopper 3, and the output side of the AC chopper 3 is connected to the primary side of the transformer 4, The rotor windings 1-3 of the wound rotor induction motor 1 are connected to the output end of the AC excitation power supply 2 through slip rings and brushes. The AC excitation power supply is composed of rectification, filtering, inverter and frequency conversion units, which complete the rectification, filtering and inverter of thre...

specific Embodiment approach 2

[0012] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 3 . The difference between this embodiment and the first embodiment is that it also includes a clutch 9 and a prime mover 12, the engine shaft of the prime mover 12 is fixed on the rotor shaft end of the wound rotor induction motor 1 through the clutch 9 to realize coaxial rotation . When the power grid and the load need to continuously compensate active power, the device of the present invention operates in the generator mode, and the prime mover can be used to drive the rotor of the wound rotor induction motor 1, and by controlling the magnitude and frequency of the output current of the AC excitation power supply 2, even When the speed of the prime mover changes, it can also output active power with a constant frequency to the grid and loads to achieve uninterrupted power supply, or supplement power supply with wind energy, water energy and other energy sources. ...

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the prime mover can be a power device such as a gas engine, a wind power engine, or a water turbine engine. Other composition and connection methods are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com