Microbe for degrading nitrite, separating and bring up method, and application

A technology of nitrite and target microorganisms, which is applied in the field of microorganisms degrading nitrite, separation, cultivation and application, and can solve problems such as nitrite pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Isolation of Bacillus megaterium CGMCC No.1627

[0018] Collect waste tobacco dust samples from the tobacco environment, add sodium nitrite, add 100mL sterile saline, and incubate at 30°C and 120rpm for 36h. According to the 10-fold dilution method to make 10 -1 、10 -2 、10 -3 , ... 10 -9 The bacterial liquid was streaked on the solid screening medium, the screening medium was glucose 1.5%, sodium nitrite 0.1%, dipotassium hydrogen phosphate 0.135%, potassium dihydrogen phosphate 0.07%, magnesium sulfate 0.02%, pH 7, agar 2 %. Select a single bacterium and carry out streak culture repeatedly until a pure bacterium is obtained, and store it on a peptone slant of beef extract for future use.

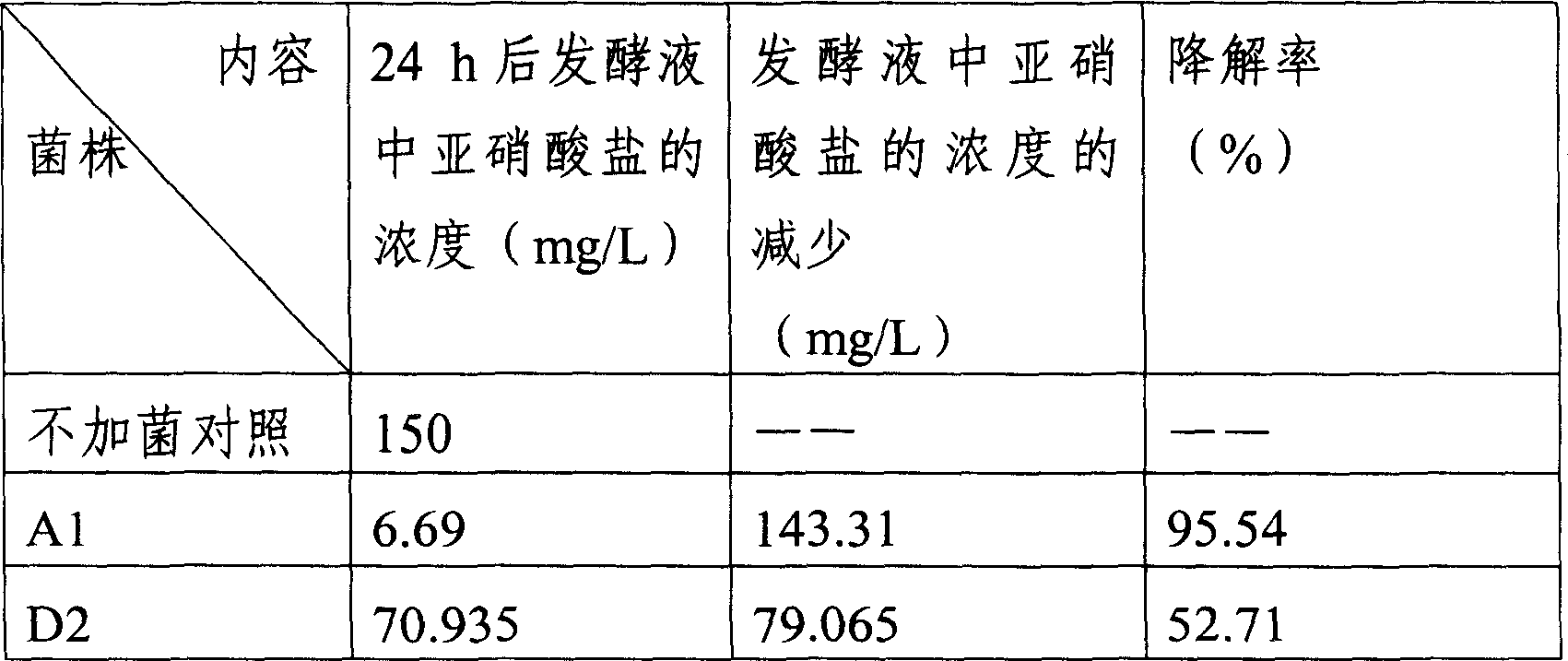

[0019] Eight strains that grew faster on the screening medium were selected for the nitrite degradation experiment. The medium used in the degradation experiment was: glucose 1.5%, sodium nitrite 0.015%, dipotassium hydrogen phosphate 0.135%, potassium dihydrogen phosph...

Embodiment 2

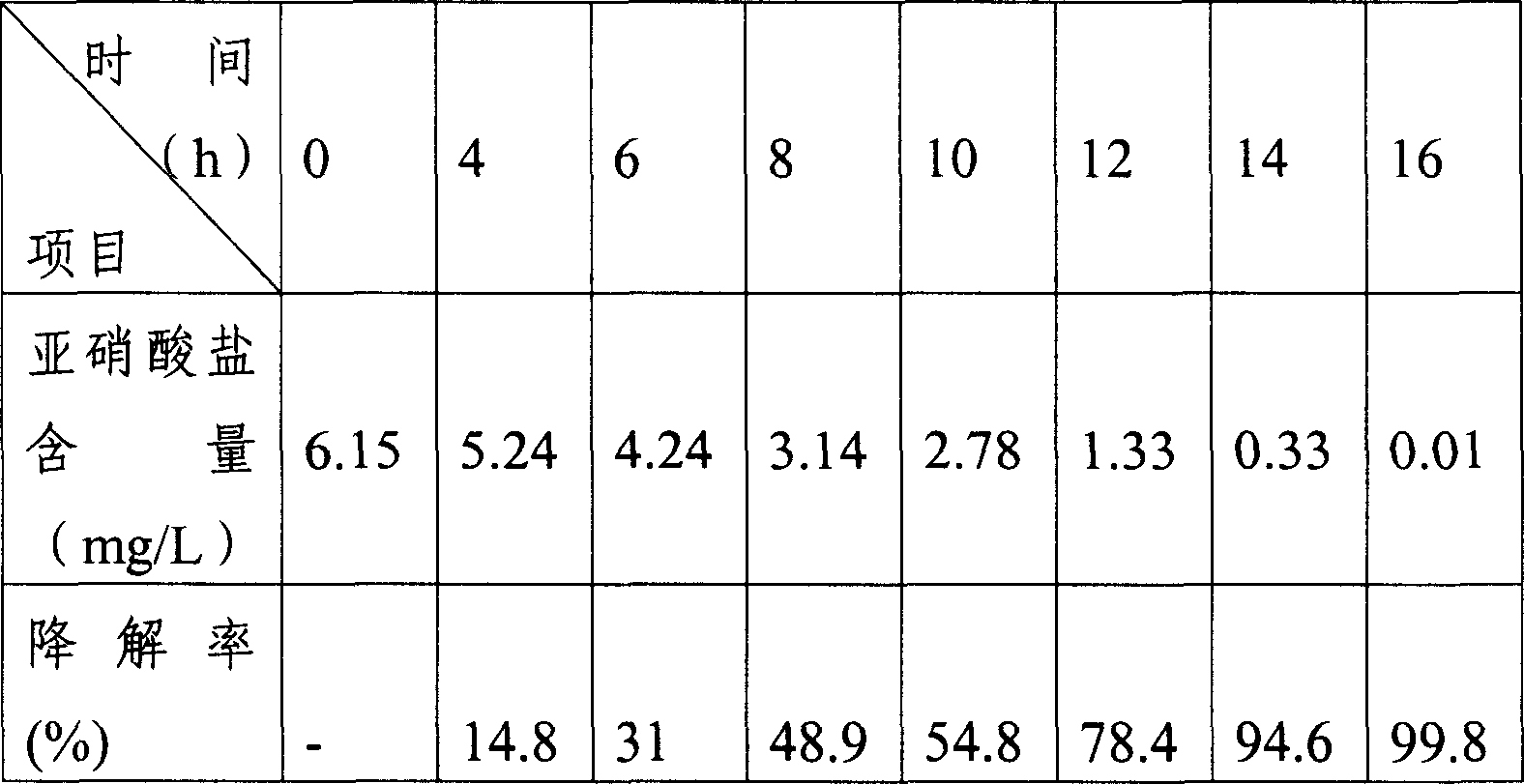

[0026] Degradation of Nitrite by Bacillus megaterium CGMCC No.1627

[0027] Bacillus megaterium CGMCC No.1627 of the present invention is inoculated in the following medium: glucose 1.5%, peptone 0.2%, sodium chloride 0.1%, dipotassium hydrogen phosphate 0.135%, potassium dihydrogen phosphate 0.07%, magnesium sulfate 0.02% , sodium nitrite 0.0138%, pH 7; the culture conditions are 30°C, 150rpm for 24h. Then the nitrite content in the culture medium was determined. Bacillus megaterium CGMCC No.1627 can degrade 99.84% of nitrite in the medium.

Embodiment 3

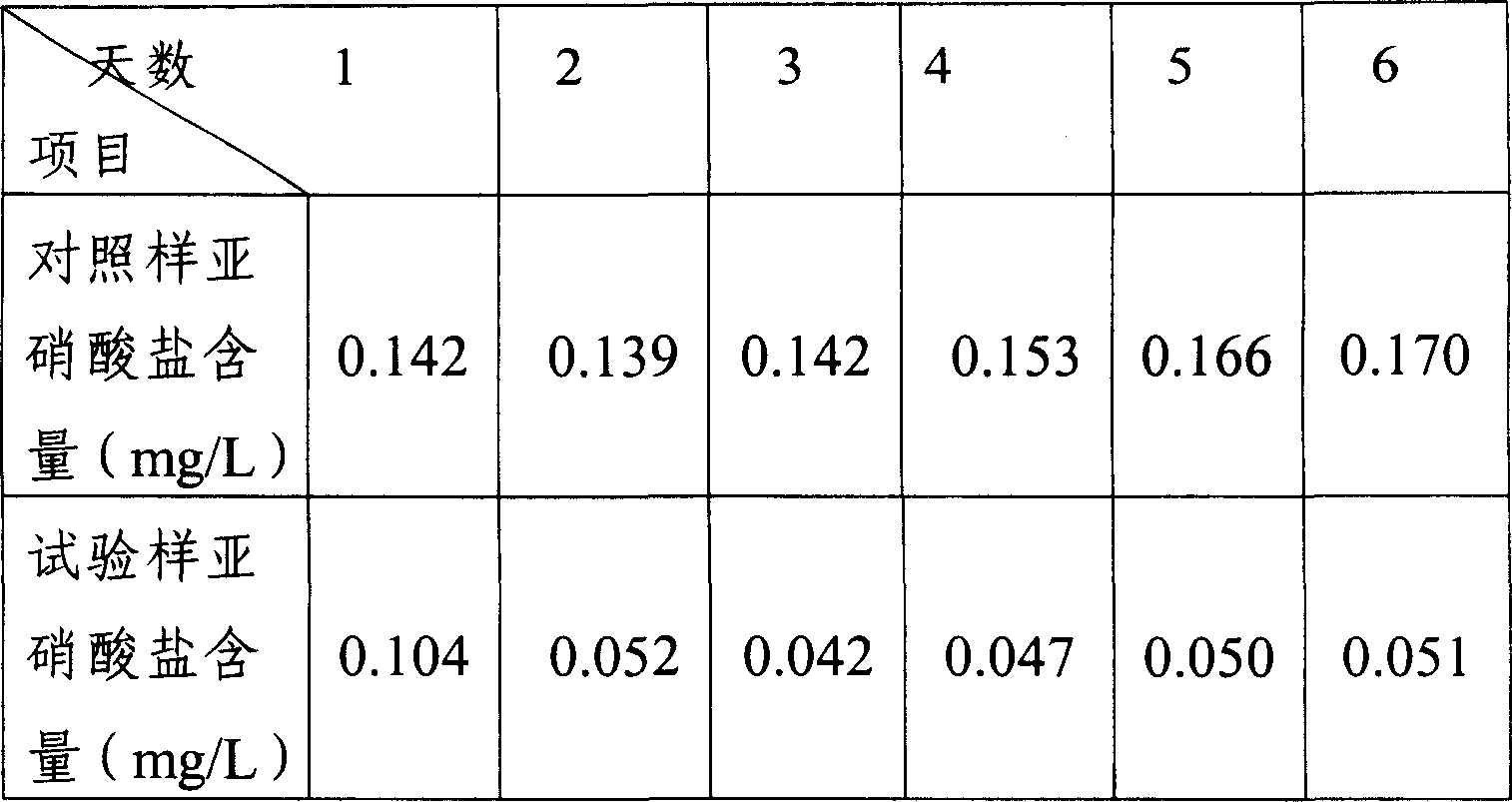

[0029] Nicotine tolerance test of Bacillus megaterium CGMCC No.1627

[0030] The basic medium used in the nicotine tolerance test is as follows: glucose 1.5%, peptone 0.2%, sodium chloride 0.1%, dipotassium hydrogen phosphate 0.135%, potassium dihydrogen phosphate 0.07%, magnesium sulfate 0.02%, sodium nitrite 0.0138 %, pH 7. By adding 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6% nicotine to the basic medium respectively, a series of mediums for testing the ability of Bacillus megaterium to tolerate nicotine are formed. Bacillus megaterium CGMCC No.1627 of the present invention was inoculated in the above-mentioned culture medium respectively, the inoculum size was 4%, cultivated at 30°C and 150rpm for 16h, and the OD of the fermentation broth was 600 Values represent the growth of Bacillus megaterium CGMCC No.1627, and the degradation rate of nitrite in the fermentation broth was determined. The results are shown in Table 2.

[0031] Nicotine concentration (%)

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com