Power converter

A power conversion device and power terminal technology, which is applied to output power conversion devices, circuits, electrical components, etc., can solve the problems of periodic on-off duty cycle limitation, high price, unavoidable enlargement and cost increase, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

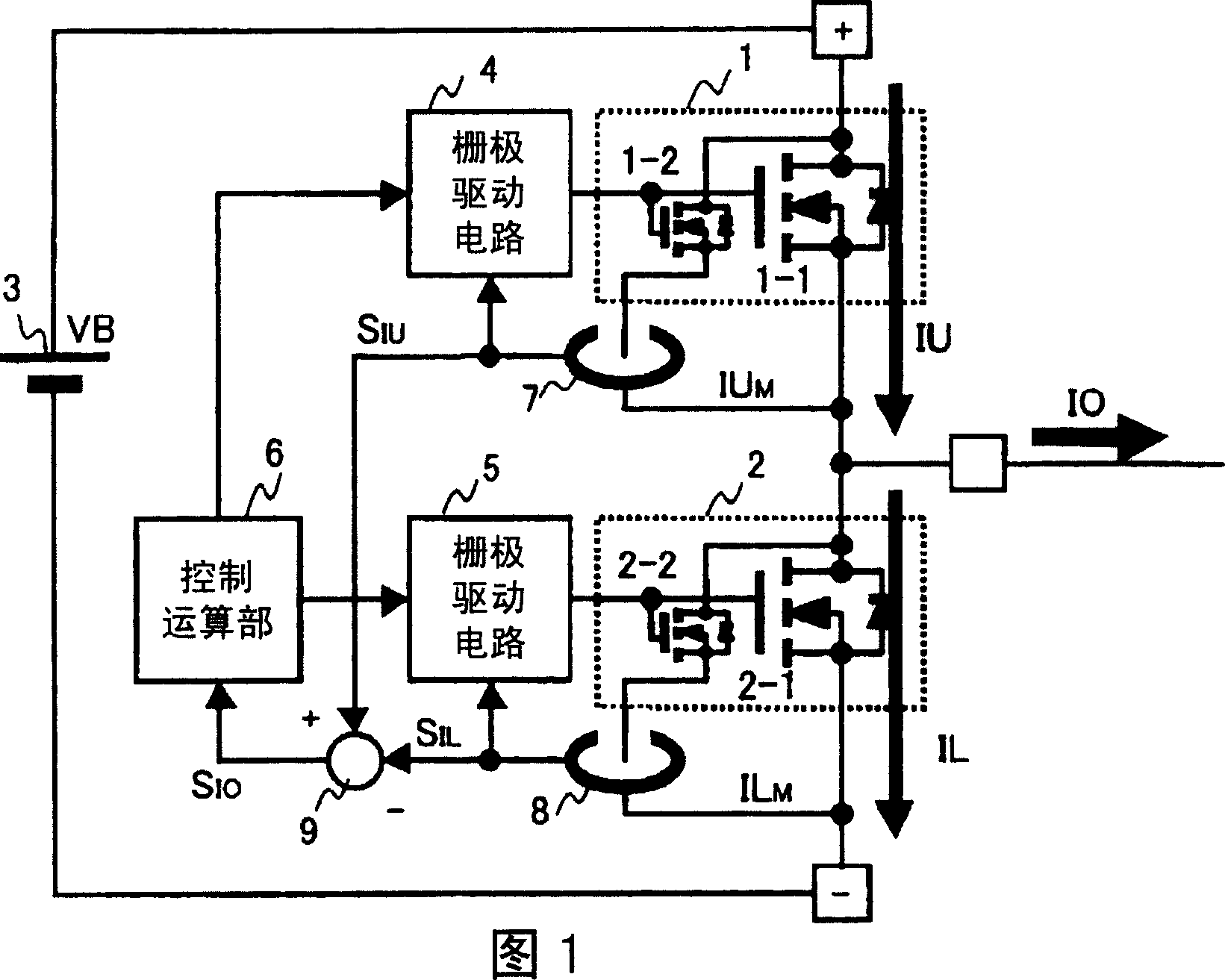

[0025] FIG. 1 shows Embodiment 1 of the present invention, which is an embodiment when the present invention is applied to, for example, an excitation chopper circuit or a switching circuit used in a motor control device disclosed in Patent Document 2 mentioned above.

[0026] Furthermore, as shown in the figure, in the first embodiment, the switching element 1 serving as the upper arm and the switching element 2 serving as the lower arm are connected in series between the + terminal and the - terminal to which the DC voltage VB is applied from the DC power supply 3 , Currents IU and IL flowing to the respective elements are switched, and an output current IO is supplied from an output terminal O to a load (not shown) such as a motor.

[0027] For this reason, each switching element 1, 2 is equipped with a gate drive circuit 4, 5 respectively, and is respectively switched and controlled under the control of the control calculation unit 6. If the switching timing and switching ...

Embodiment approach 2

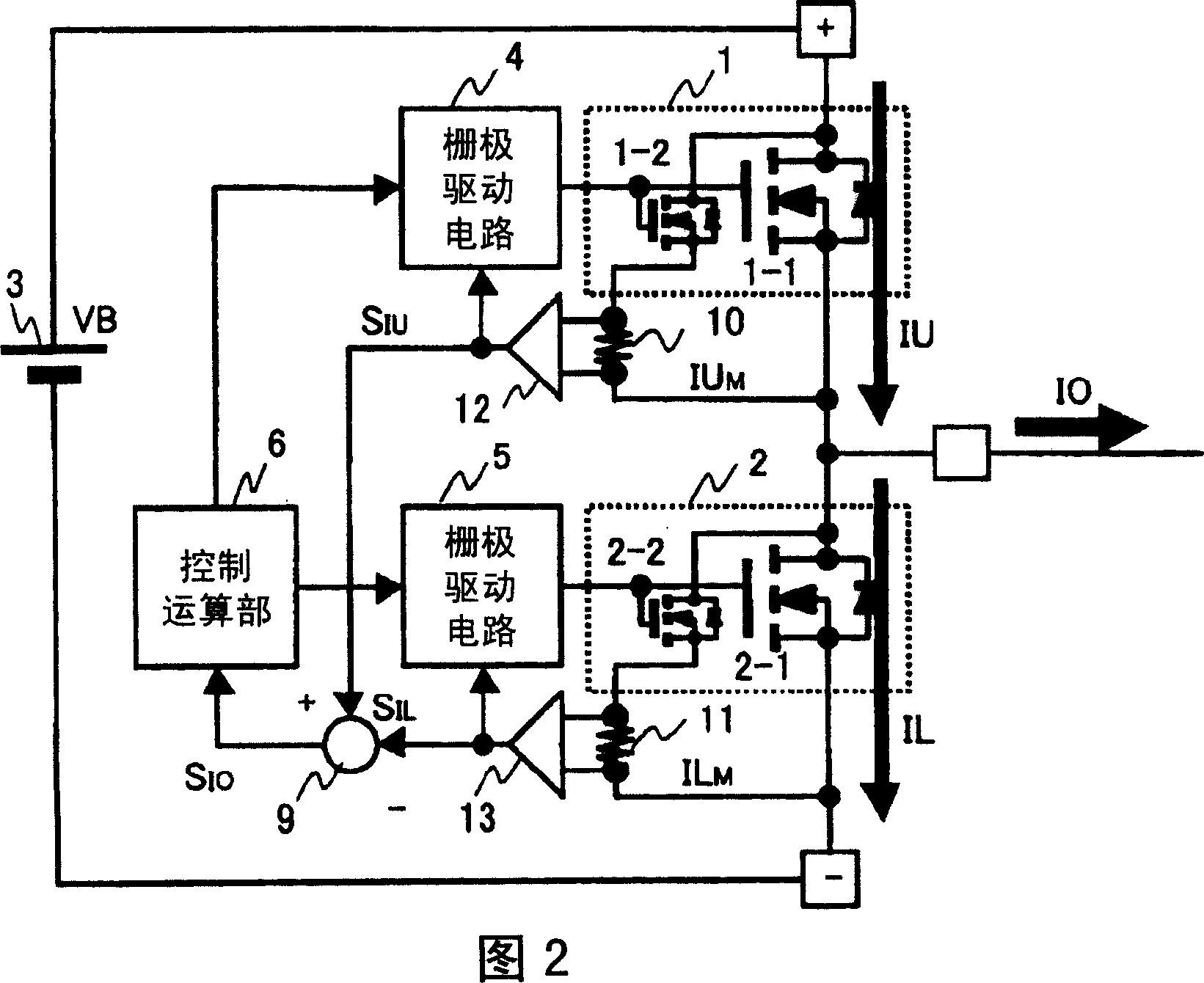

[0042] Next, Embodiment 2 of the present invention will be described based on FIG. 2 . Here, this Embodiment 2 is an embodiment of the present invention when the Miller current is detected by the shunt resistance. For this purpose, shunt resistances 10, 11 are inserted into the respective Miller elements 1-1, 2 as shown in the figure. -2 current paths, differential circuits 12 and 13 are connected in parallel to them, and other constituent elements are the same as those of Embodiment 1 shown in FIG. 1 .

[0043] First, the shunt resistor 10 generates the Miller current IU based on the Miller element 1-2 M The differential circuit 12 operates as follows: the voltage drop is detected to obtain a detection signal S indicating the current IU flowing in the switching element 1 of the upper arm. IU , on the other hand, the shunt resistor 11 produces the Miller current IL based on the Miller element 2-2 M The differential circuit 13 operates as follows: the voltage drop is detected...

Embodiment approach 3

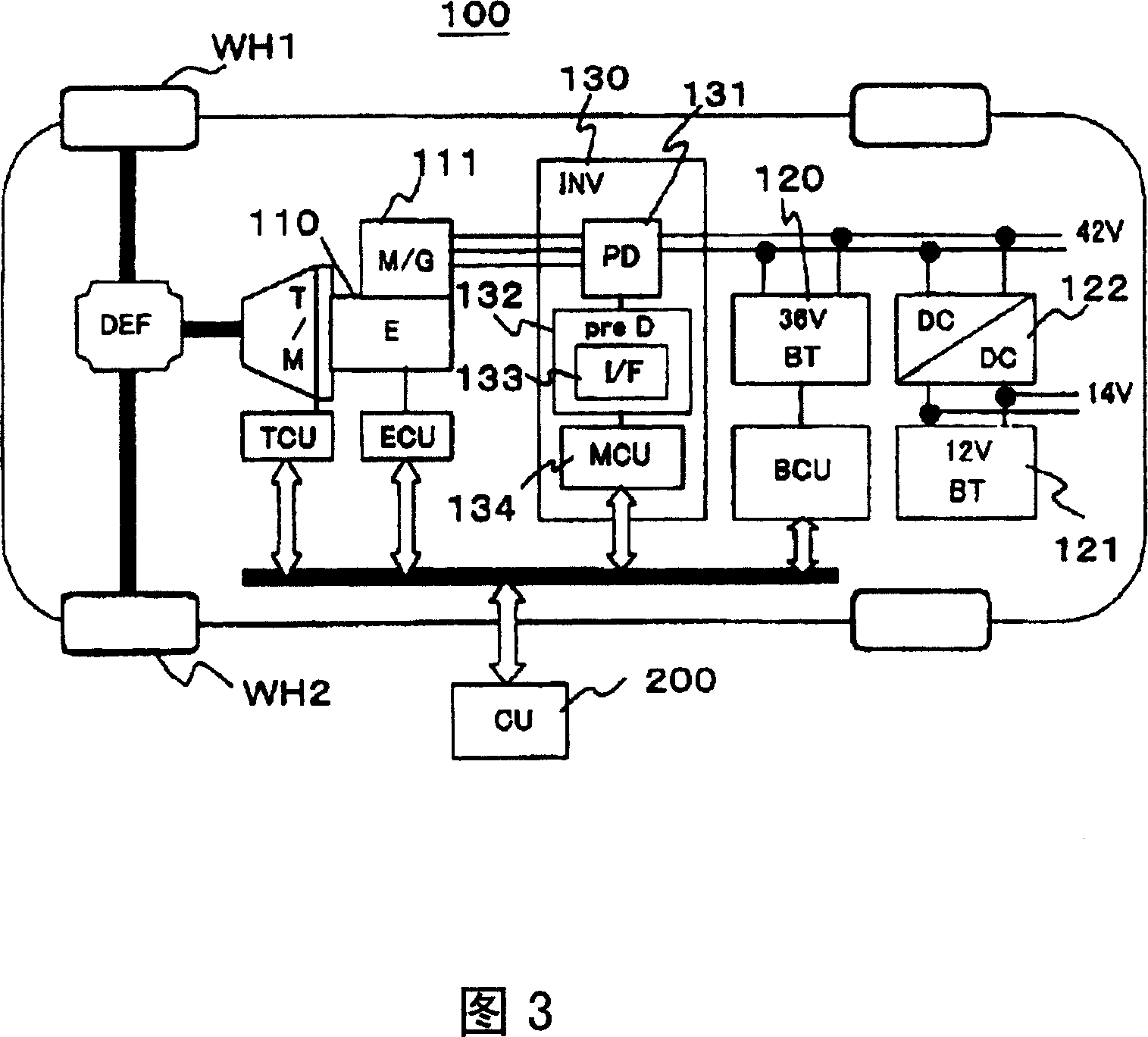

[0051] Next, as Embodiment 3, a vehicle equipped with a power conversion device according to the present invention will be described with reference to FIG. 4 . Here, the vehicle according to Embodiment 3 is shown as an automobile 100 , and uses, for example, an engine 110 such as a gasoline engine as a power source.

[0052] Moreover, when the automobile 100 is running, the torque of the engine 110 is transmitted to the wheels WH1 and WH2 through the transmission (transmission) device T / M and the differential gear device DEF. At this time, the engine 110 and the M / G (generator) The 111 connection makes the M / G 111 operate not only as a normal alternator but also as a starter for the electric motor 110 .

[0053] Therefore, the M / G 111 operates as an alternator while the engine 110 is rotating, and charges the two secondary batteries, the main battery 120 with a terminal voltage of 36V and the auxiliary battery 121 with a terminal voltage of 12V, and the engine 110 At the time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com