Burner for combustion of a low-calorific fuel gas and method for operating a burner

A burner, low calorific value technology, applied in combustion methods, burners, combustion chambers, etc., can solve the problem of difficult to achieve good mixing of combustion air and syngas, avoid flashback, reduce pressure loss, improve The effect of spatial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

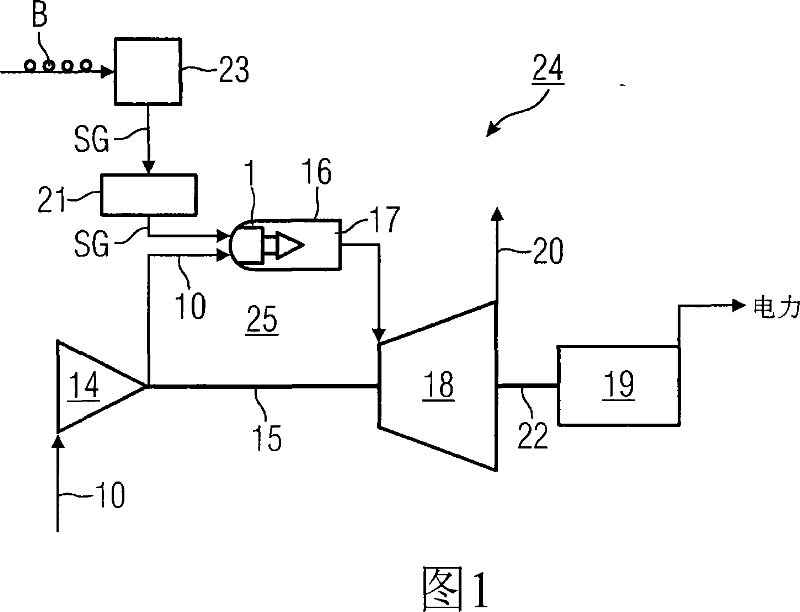

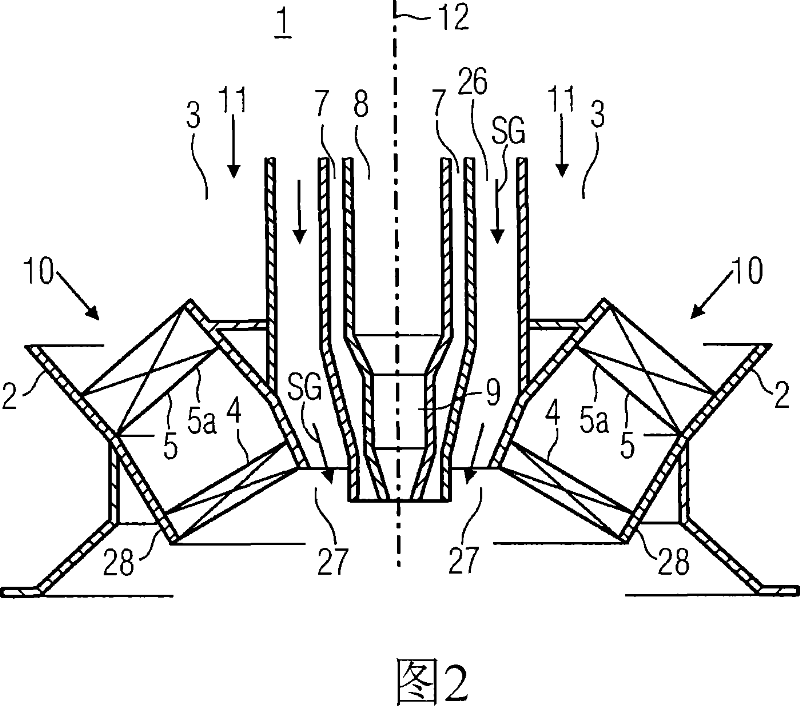

[0038] The power plant installation 24 shown in FIG. 1 comprises a gas turbine plant 25 and a gasification plant 23 for gasifying a fossil fuel B connected upstream of the gas turbine plant 25 . The gas turbine arrangement 25 includes a compressor 14 , a combustion chamber 16 and a turbine 18 connected downstream of the combustion chamber 16 . Compressor 14 and turbine 18 are coupled via a common rotor shaft 15 . A generator 19 connected downstream of the turbine 18 is coupled to said turbine via a generator shaft 22 . The combustion chamber 16 comprises a combustion space 17 and a burner 1 protruding into the combustion space 17 for burning a low calorific value gas SG obtained by gasifying a fossil fuel B in a gasification device 23 gas.

[0039] During operation of the gas turbine 18, air 10 is drawn into the compressor 14, where the air is highly compressed. The compressed air 10 is then fed to the burner 1 as combustion air 10 and mixed with the low calorific value gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com