Operating mechanism of valve for removing flue gas and fire proofing

A technology for an actuator and a smoke exhaust valve, which is applied in fire rescue and other directions, can solve the problems of detonation, the material and structure of the fire exhaust valve actuator can not meet the requirements of sealing and explosion-proof, and is affected by radiation, etc., to achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

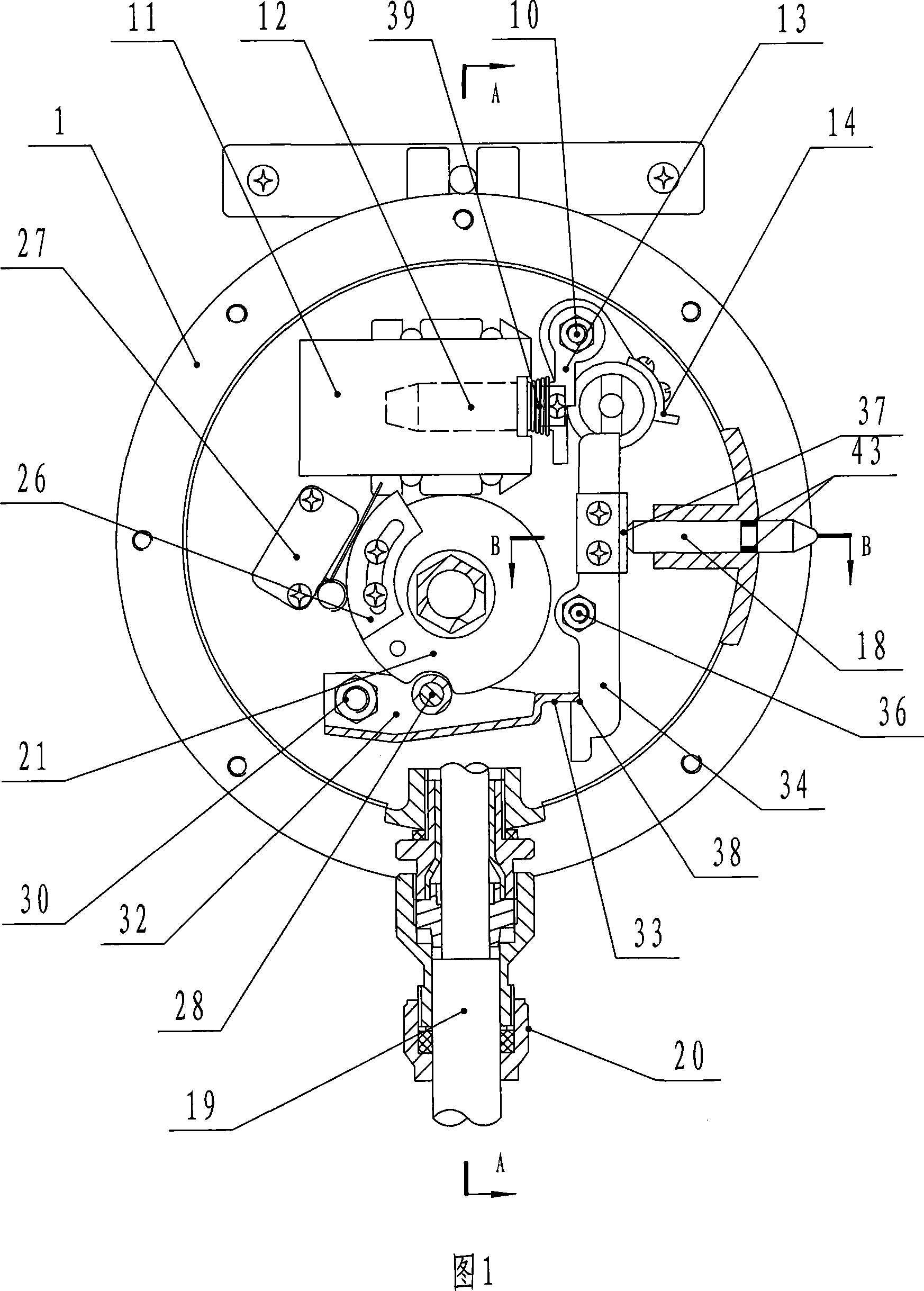

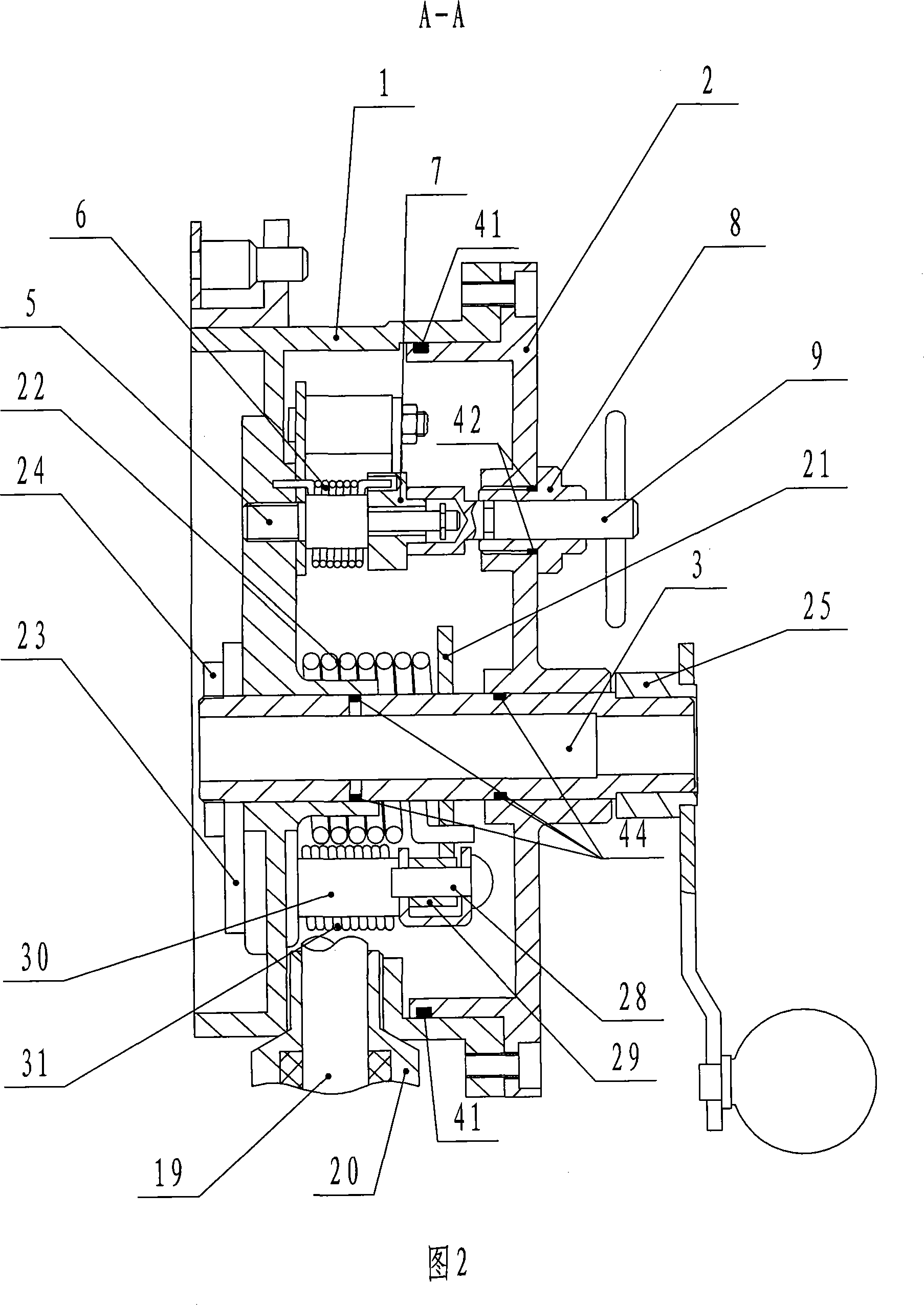

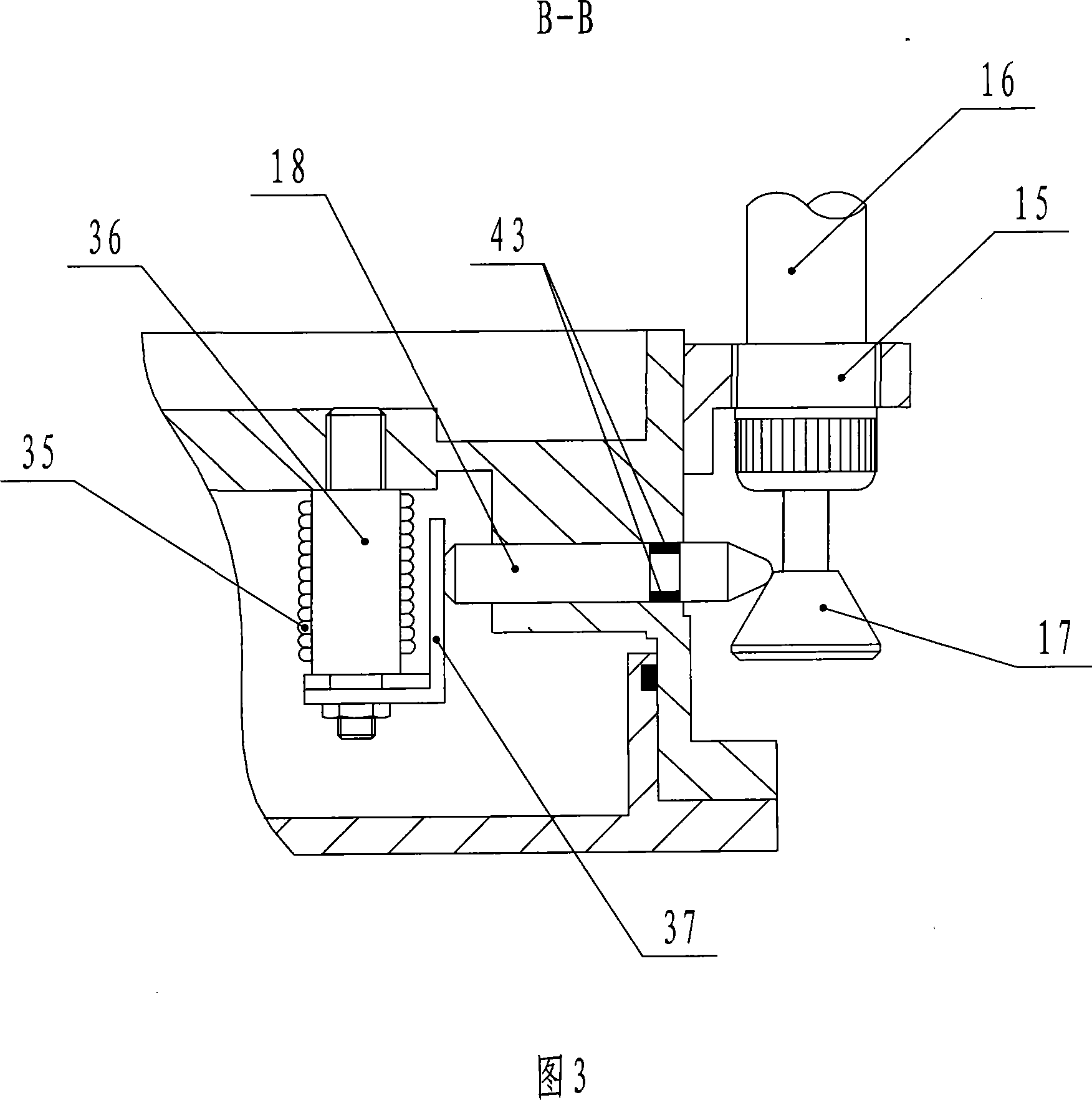

[0019] The actuator of the present invention mainly includes a flameproof casing 1, a flameproof casing cover 2, a rotating spindle assembly, a pendulum assembly, an electromagnet, a micro switch 27, a swing rod assembly, an electrical circuit assembly, a temperature sensor assembly and a floating point support Components and other parts.

[0020] As shown in Figure 1, Figure 2 and Figure 3, the same as the existing actuators, the rotating main shaft assembly is mainly centered on the rotating main shaft 3, and the rotating main shaft 3 is sequentially equipped with a handle 25, a cam 21, and a main shaft torsion spring from top to bottom 22. The main shaft sleeve 23 and the main shaft splicing cap 24, the cam 21 is welded and fixed on the rotating main shaft 3, the upper end of the rotating main shaft 3 passes through the flameproof shell cover 2, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com