High-elastic and non-deforming sizing materials of front uppers of shoes, their production of non-deforming front uppers

A technology of shaping materials and manufacturing methods, which is applied in the direction of shoe uppers, footwear, footwear, etc., and can solve problems such as wrinkles, affecting the beautiful shape of shoes, and not being able to maintain the original shape of shoes for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

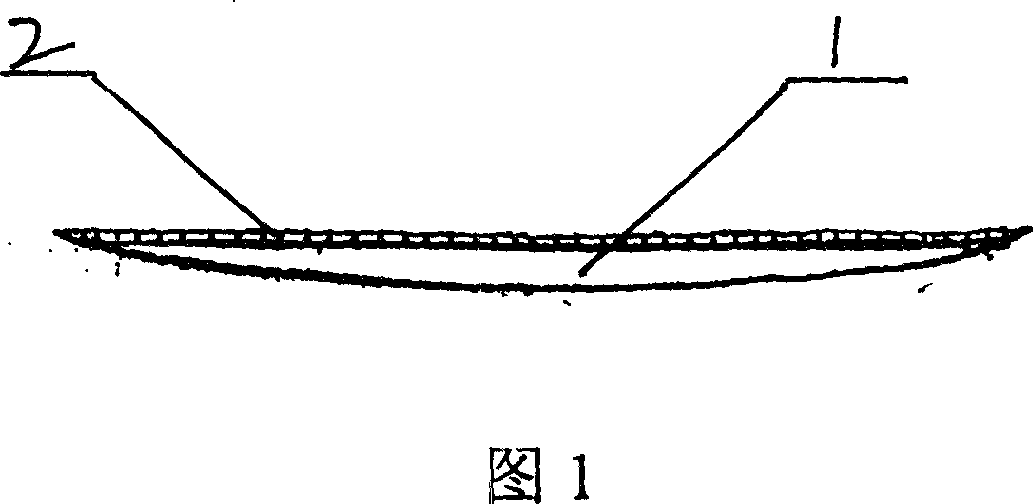

[0031] As shown in Fig. 1, the sizing material 5 of the present invention is a combination of rubber 1 and cloth 2, and is a sheet-like combination formed by setting a layer of cloth on the rubber.

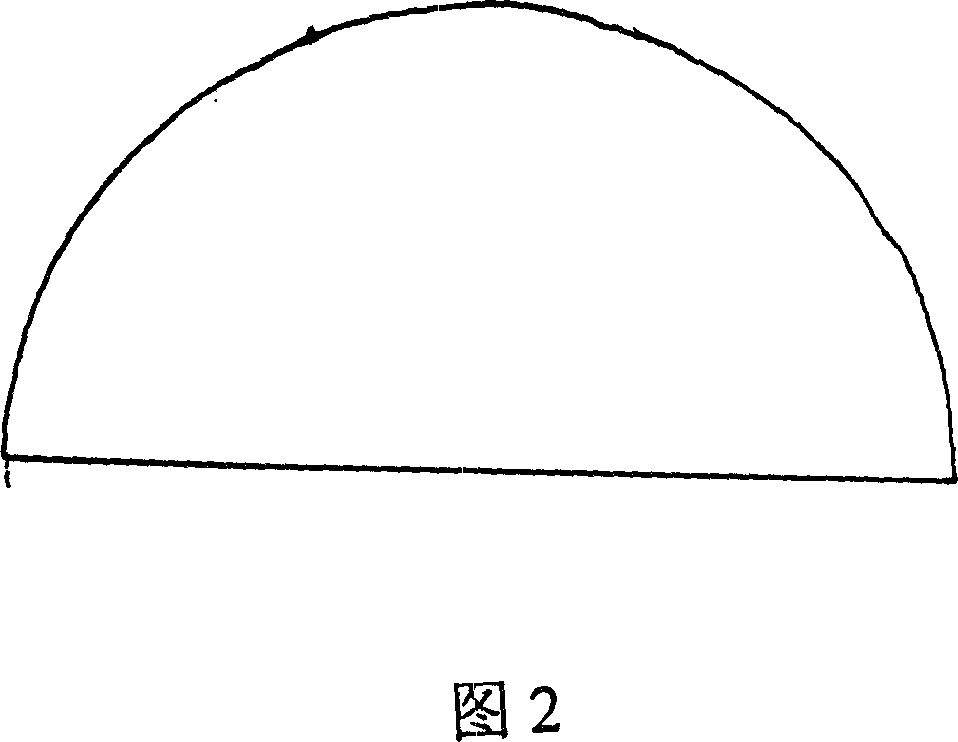

[0032] As shown in Figures 1, 2, 3, 4, and 5, the specifications of the shaping material are: the length is 3 cm-16 cm, the width is 3 cm-16 cm, and the thickness is thick in the middle and thin at the edge, and the thickest part of the material 0.2mm-3mm, the shape is one of semicircle, half moon, semicircle, trapezoid.

[0033] The combination formed by placing a layer of cloth on the rubber sheet refers to an elastic sheet shaped material formed by fusing rubber and cloth into one body after pressurized, heated and vulcanized. One side is rubber and the other side is cloth.

[0034] A kind of manufacture method of high elasticity invariable shoe upper shaping material, concrete steps are as follows:

[0035] (1), first select the material, choose the mature rubber that has not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com