Air filtering apparatus

An air sterilization and air technology, which is used in air humidification systems, air quality improvement, deodorization and other directions, can solve the problems of electrolyte infiltration, reduce air sterilization efficiency, hinder water permeability of the split sheet, etc., to prevent sterilization efficiency. The effect of reducing and reducing the sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

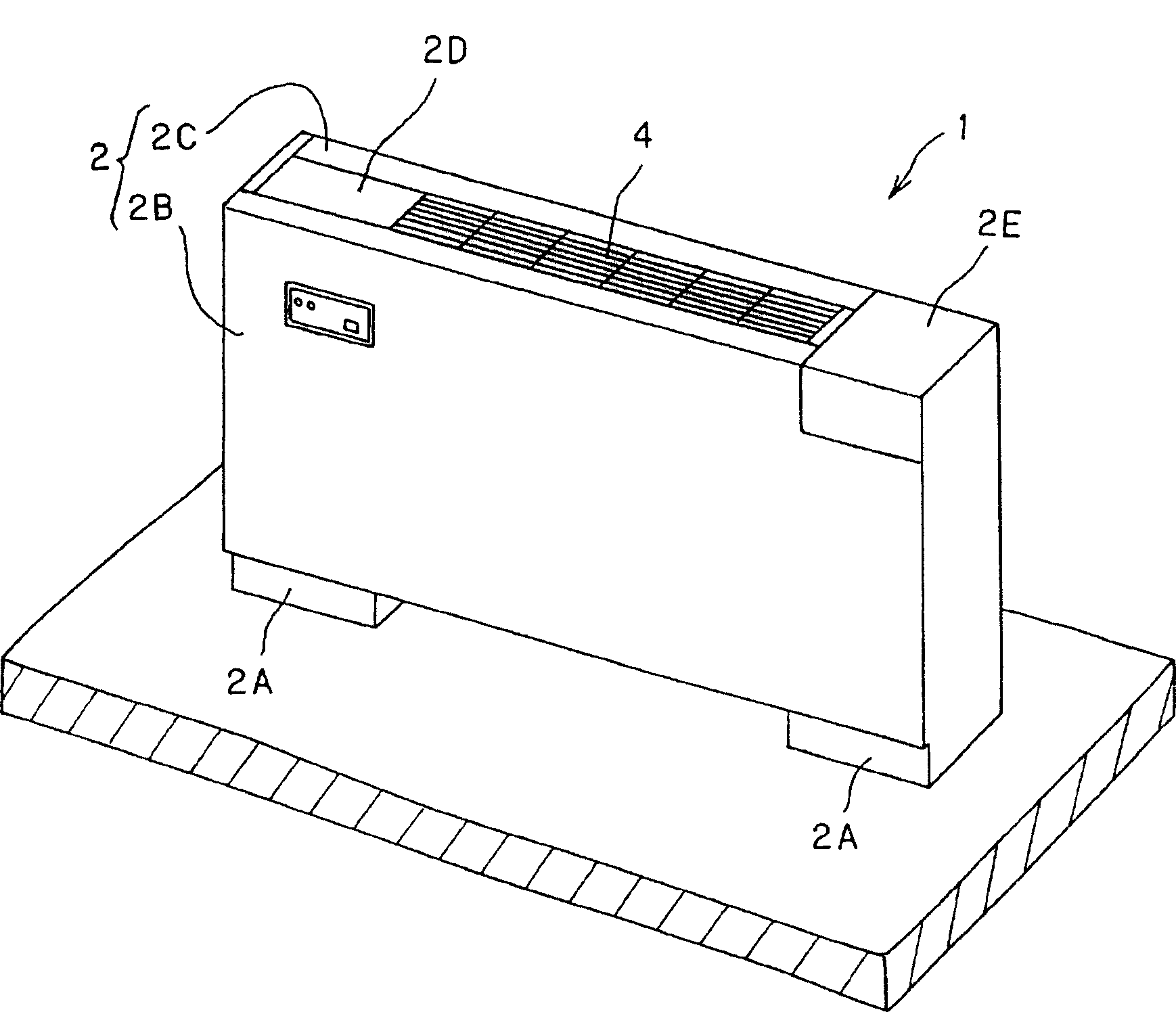

[0039] figure 1 Among them, symbol 1 represents a vertical air sterilization device. The vertical air sterilization device 1 has a box-shaped frame body 2, which includes a stand 2A, a front plate 2B, and a top plate 2C, and an operation cover 2D and an opening and closing cover 2E are arranged in rows on both sides of the top plate 2C. .

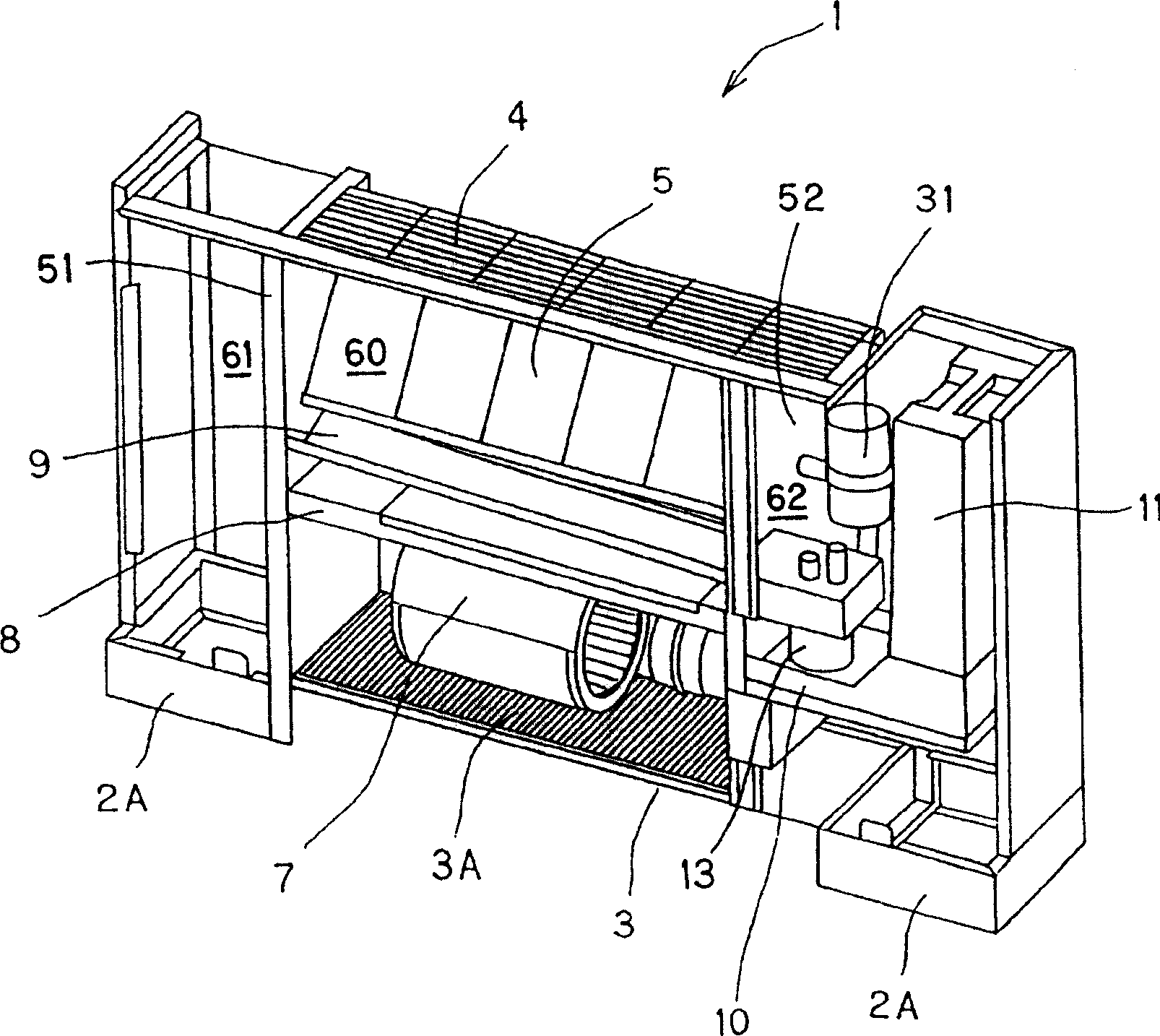

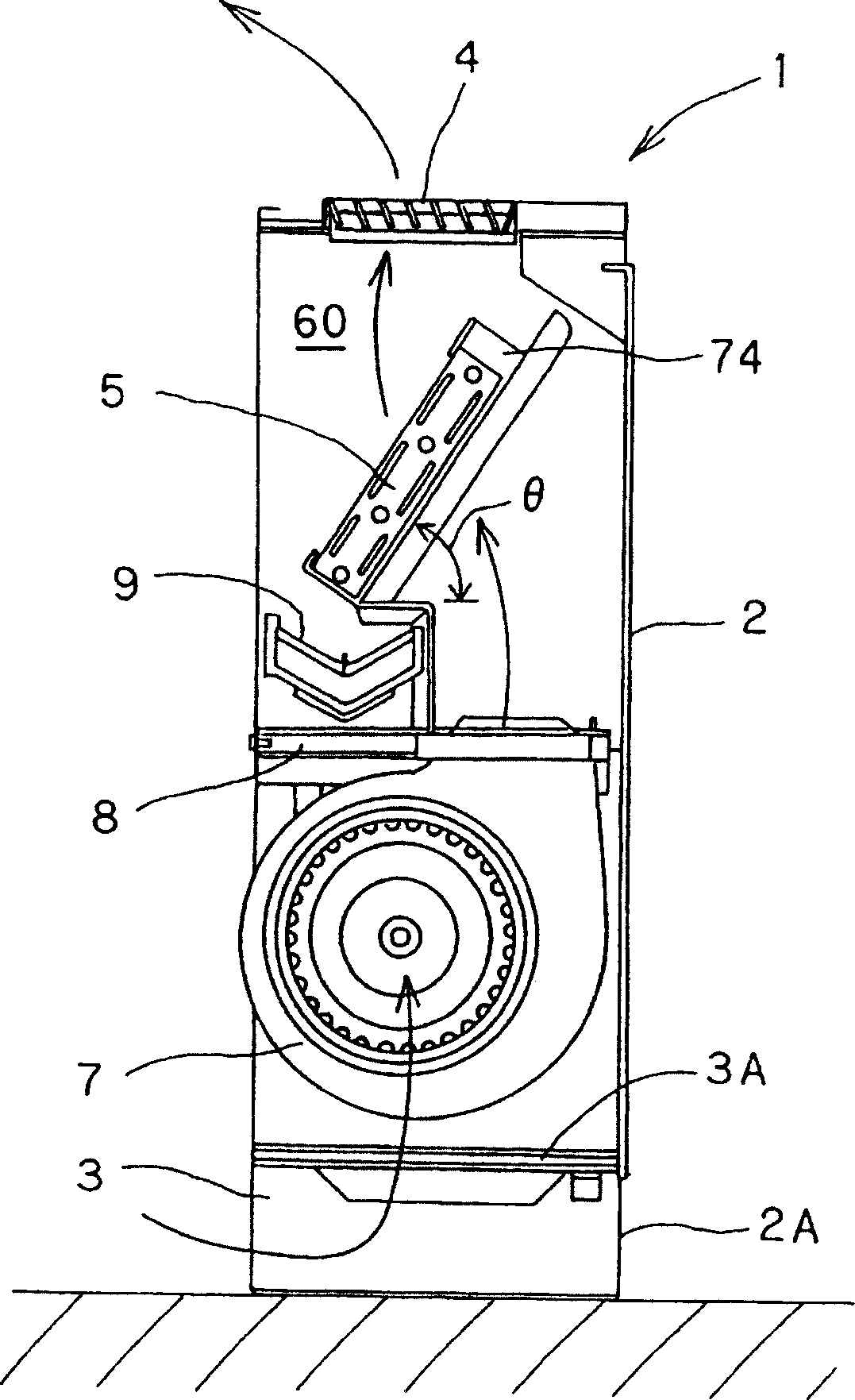

[0040] Such as figure 2 As shown, the inside of the frame body 2 is provided with two partitions 51, 52 extending in the up and down direction, and the inside of the above-mentioned frame body 2 is divided into three chambers (sterilizing chamber 60, electric chamber 60, electric chamber) by these partition plates 51, 52. Dress chamber 61, water supply chamber 62). A horizontally long air inlet 3 is formed at the lower portion of the sterilization chamber 60 formed in the center of the housing 2 , and a prefilter 3A is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com