Double-camera calibrating method in three-dimensional scanning system

A dual-camera, three-dimensional scanning technology, used in image communication, image analysis, image data processing, etc., can solve problems such as no imaging center correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

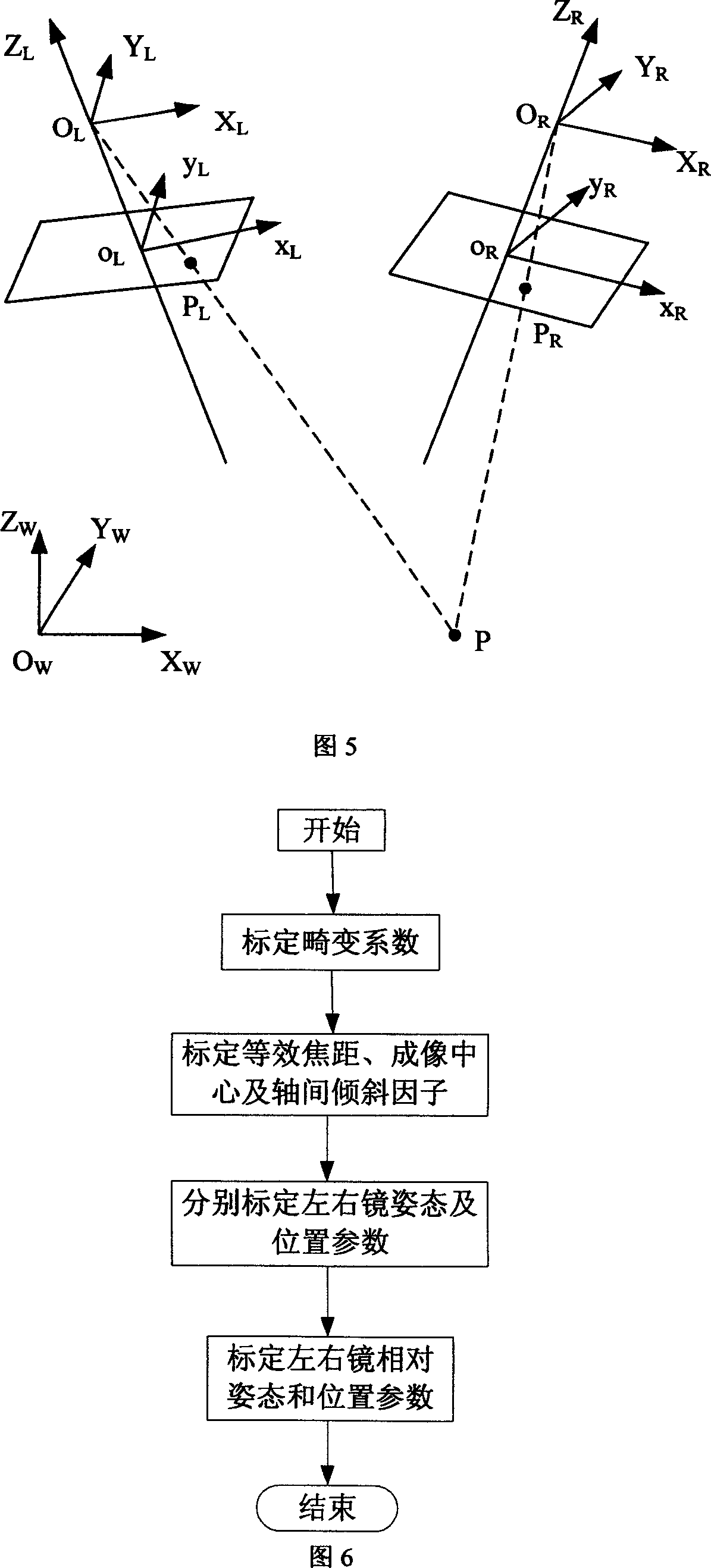

[0056] The dual-camera calibration in the 3D scanning system includes: firstly calibrate the distortion coefficient; then use the distortion coefficient to correct the captured image, and then combine the ideal pinhole perspective model to calibrate the internal parameters of the camera. The internal parameters of the camera mainly include the imaging center, The inter-axial tilt factor and the equivalent focal length; finally, the external parameters of the left and right cameras are calibrated according to the internal parameters of the cameras, and the relative external parameters of the left and right cameras are calibrated by further using the external model of the dual cameras, which are characterized in that:

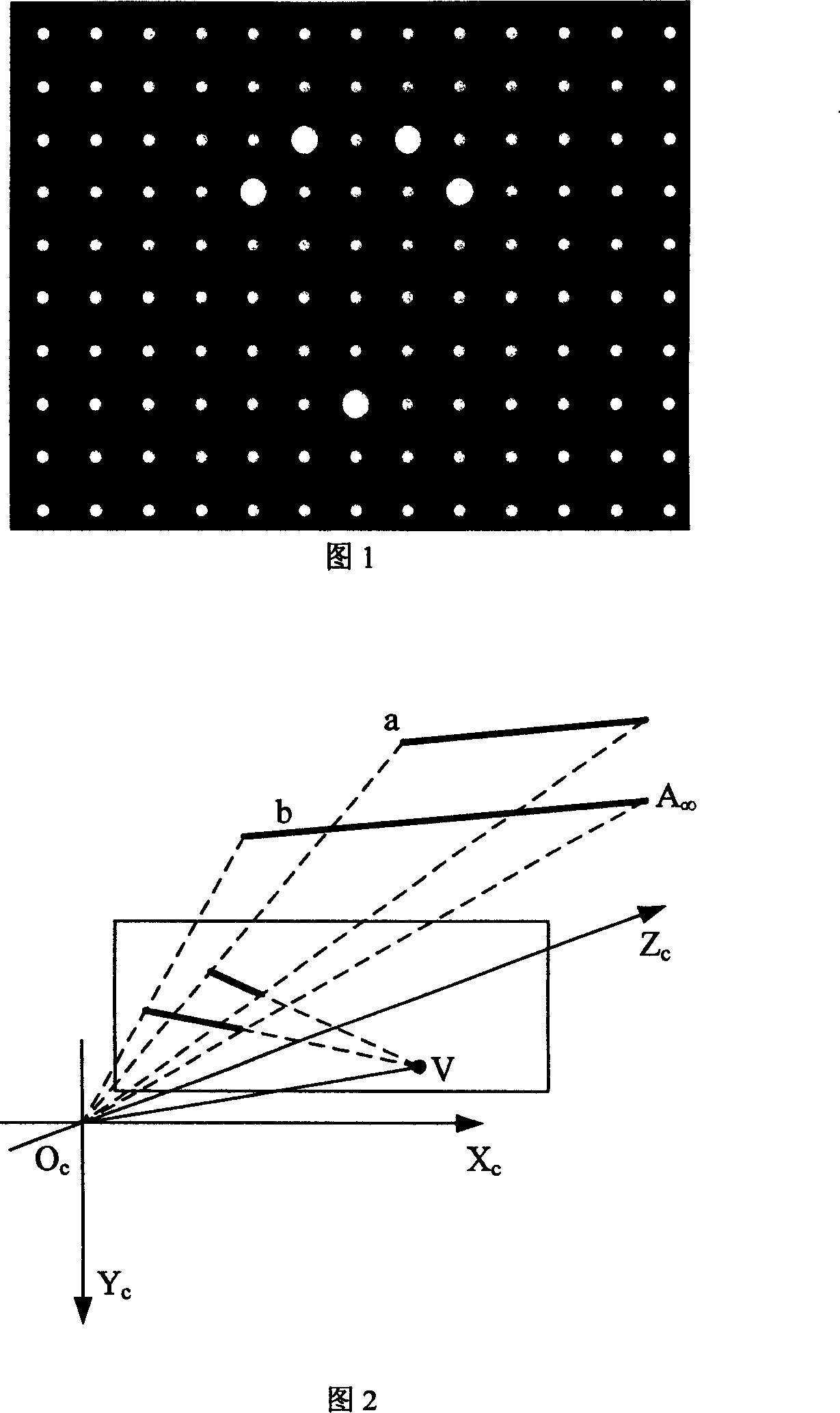

[0057] (1) Calibration of distortion coefficient

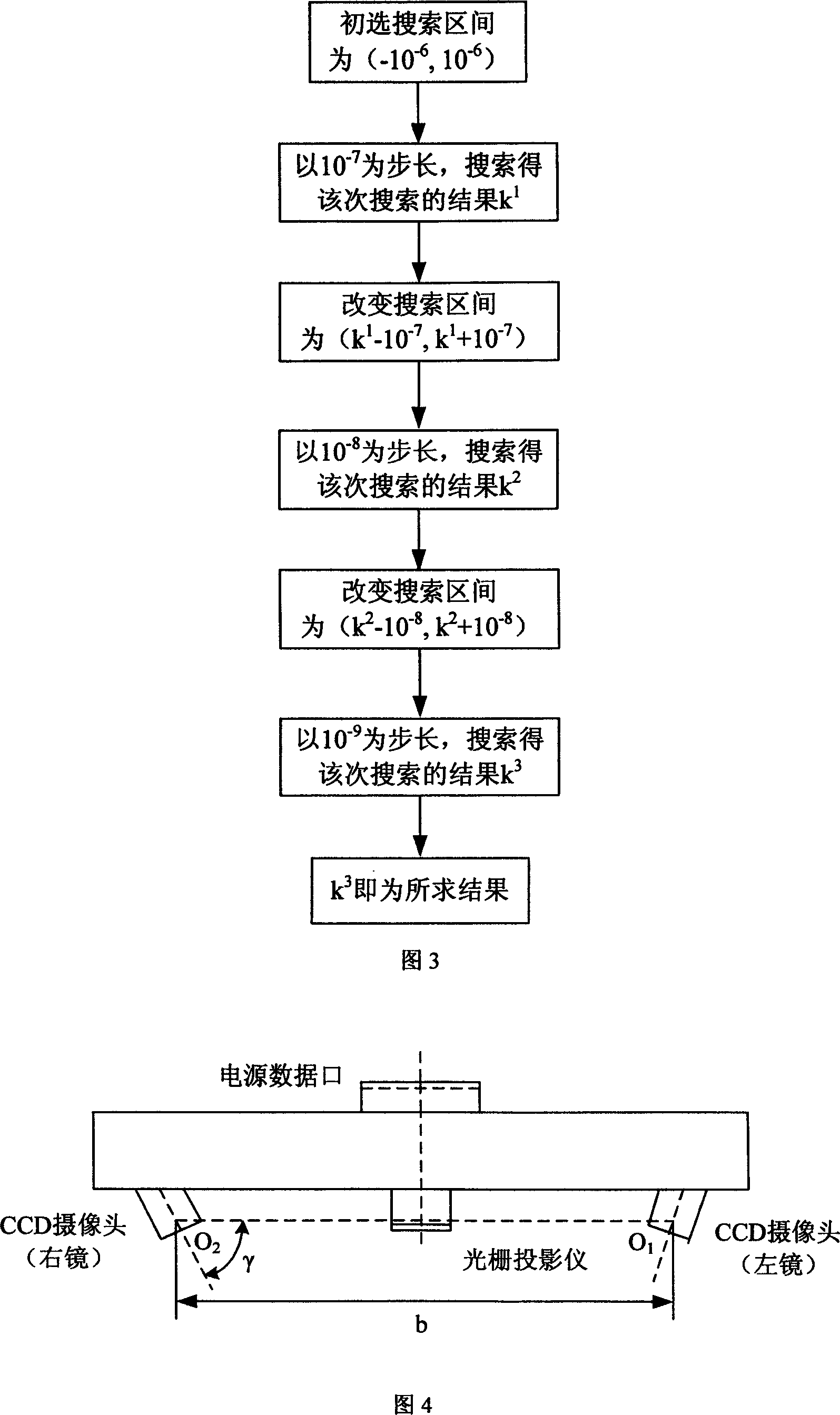

[0058] Use a group of marking dots on the parallel lines on the calibration plate, and according to the basic principle of linear perspective projection, use parallel lines to project the intersection point on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com