Fruit vinegar fermenting tank

A fermenter and fruit vinegar technology, which is applied in the field of new fruit vinegar fermenter, can solve the problems of cumbersome vinegar film treatment on the bacterial bed, achieve high acid production efficiency, reduce floor space, and be easy to sterilize and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

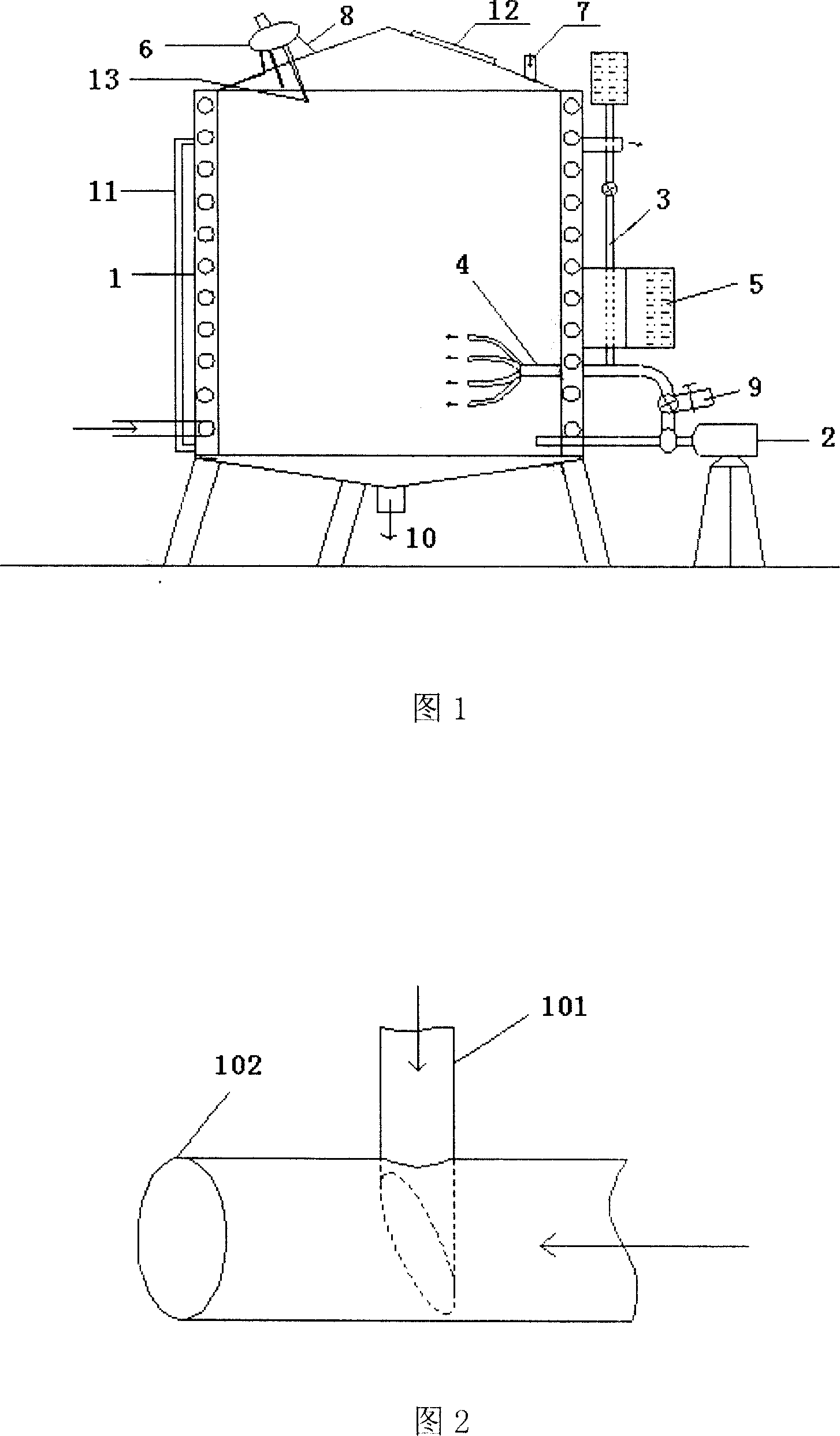

[0020] Referring to Fig. 1, Fig. 1 is a specific embodiment of the present invention, and its structural feature comprises tank body 1, and this tank body 1 is interlayer, and the bottom of tank body 1 is provided with sewage outlet 10, and the side below of tank body 1 is equipped with centrifugal pump 2. The centrifugal pump 2 is connected with an injection system 4, an air intake system 3 and a discharge port (or called a sampling port) 9. The air intake system 3 includes an air intake pipe, an air filter and an air flow regulator; above the tank body 1 It is equipped with a feed port 7, an exhaust port 8, an observation window 12 and a mechanical defoamer 6; the mechanical defoamer 6 communicates with the exhaust port 8, and the exhaust port 8 is equipped with a foam probe connected with the mechanical defoamer 6 13. A liquid level gauge 11 and a control panel 5 are also installed on the side of the tank body 1.

[0021] The tank body 1 is designed with stainless steel or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com