Phthalic anhydride reactor

A technology for reactors and reactor shells, applied in the direction of organic chemistry, etc., can solve the problems of accidents, increase in the number of tube bundles, losses, etc., and achieve the effects of preventing local overheating, slow circulation, and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

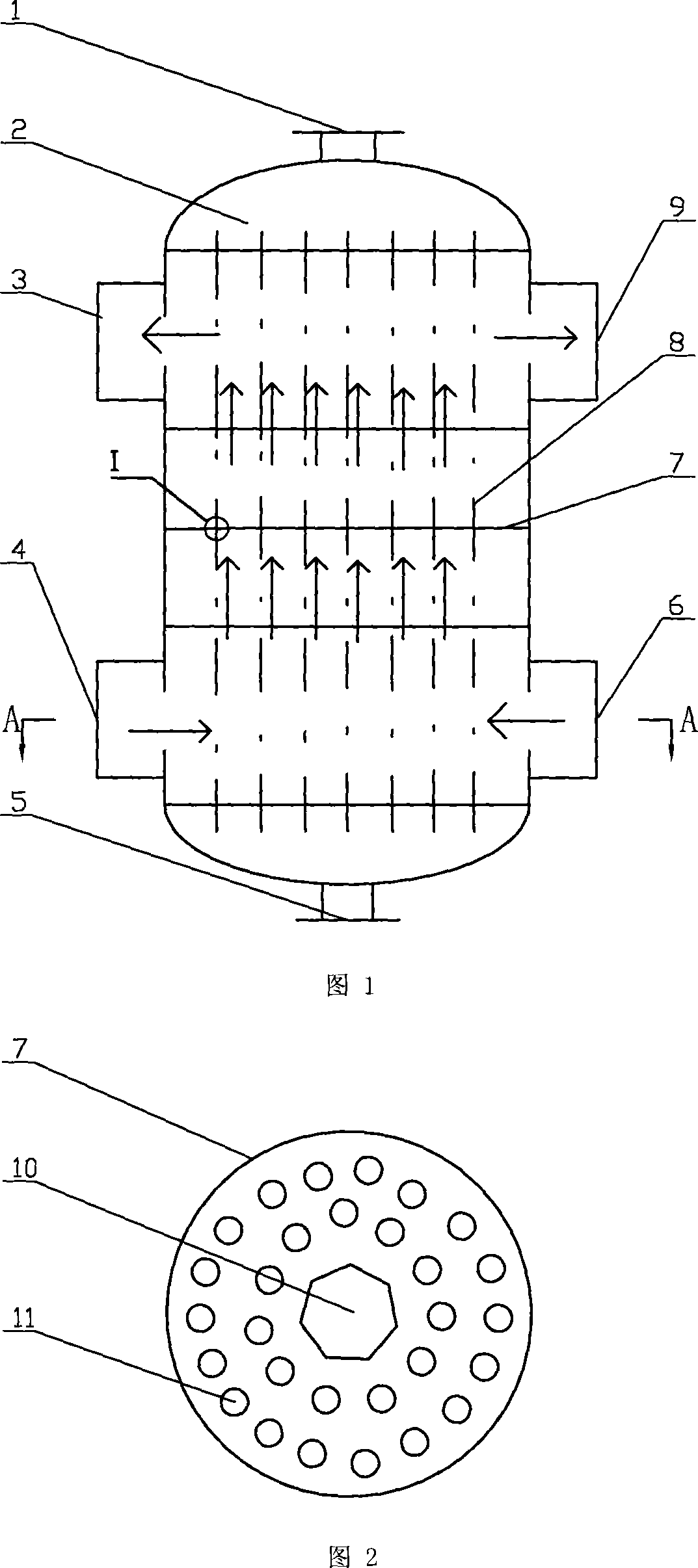

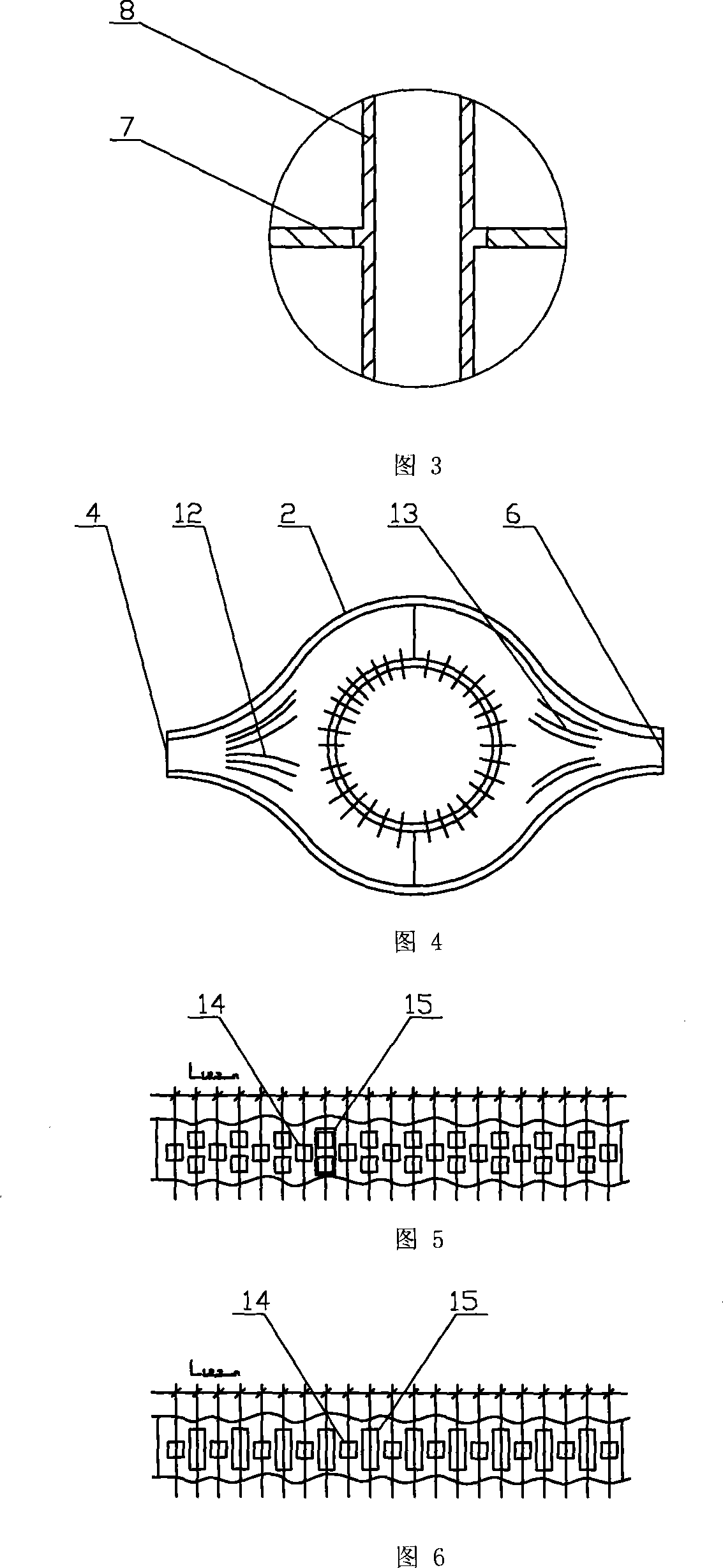

[0017] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the upper and lower ends of the cylindrical reactor shell 2 are provided with an air inlet 1 and an air outlet 5, and the side of the reactor shell 2 is provided with There are horn-shaped molten salt inlet 4, molten salt inlet 6, molten salt outlet 3, molten salt outlet 9 symmetrically distributed, and molten salt inlet 4, molten salt inlet 6, molten salt outlet 3, molten salt outlet 9 are in the reactor The ratio of the opening area on the shell 2 to the area of the molten salt channel is 2, and the reactor shell 2 is provided with a circular baffle 7, and the baffle 7 is provided with a circular tube hole 11, and the tube hole The ratio of the diameter of 11 to the outside environment of the tubes 8 is 1.2:1, the tubes 8 pass through the tube holes 11 and are fixed inside the reactor shell 2, and the baffles 7 are provided with a regular hexagonal central hole 10, There are no pipes in this area, and arc-shaped...

Embodiment 2

[0020] As shown in Figure 1, Figure 2, Figure 3, Figure 4, and Figure 6, there are small holes and large holes interlaced on the shell at the molten salt inlet 4, molten salt inlet 6, molten salt outlet 3, and molten salt outlet 9. For the molten salt channels arranged, the small holes 14 are square holes, the large holes 15 are long holes, and the others are the same as in Embodiment 1.

[0021] The present invention is not limited to the above embodiments. The ratio of the diameter of the tube hole on the baffle to the outer diameter of the tube bundle can be any other value between 1.2:1 and 1.5:1. The molten salt inlet and the molten salt outlet are in the reaction The ratio of the opening area on the shell to the area of the molten salt channel can also be any other value between 2 and 3. The hole in the molten salt channel can also be a round hole or other shapes. The center of the baffle plate The holes can also be circular or other regular polygons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com