Lock head device

A lock head and lock cylinder technology, which is used in construction locks, cylinder pin locks, locks with turning keys, etc., can solve the problems of high mutual opening rate, failure to achieve anti-theft effect, loss of anti-theft performance, etc., and achieve the manufacturing process. Simple and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

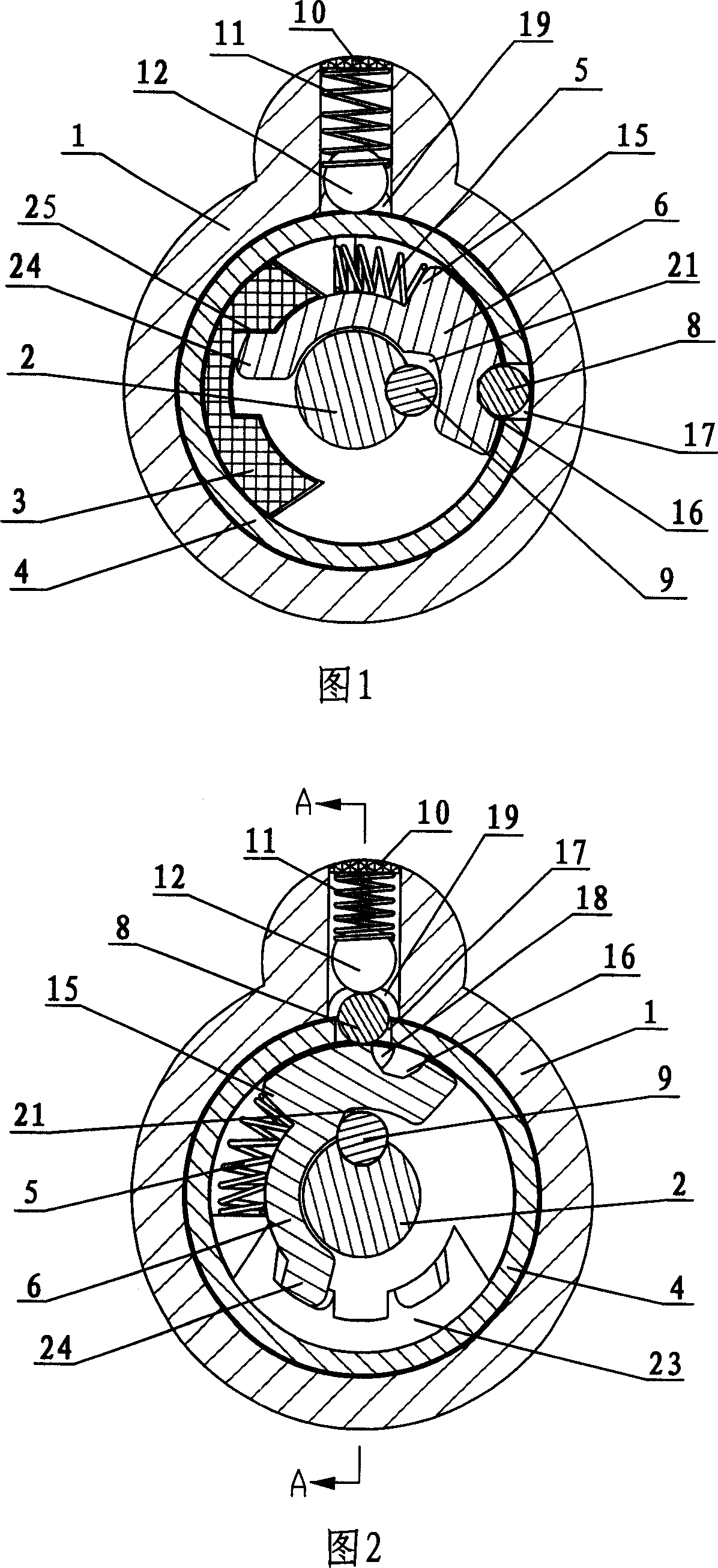

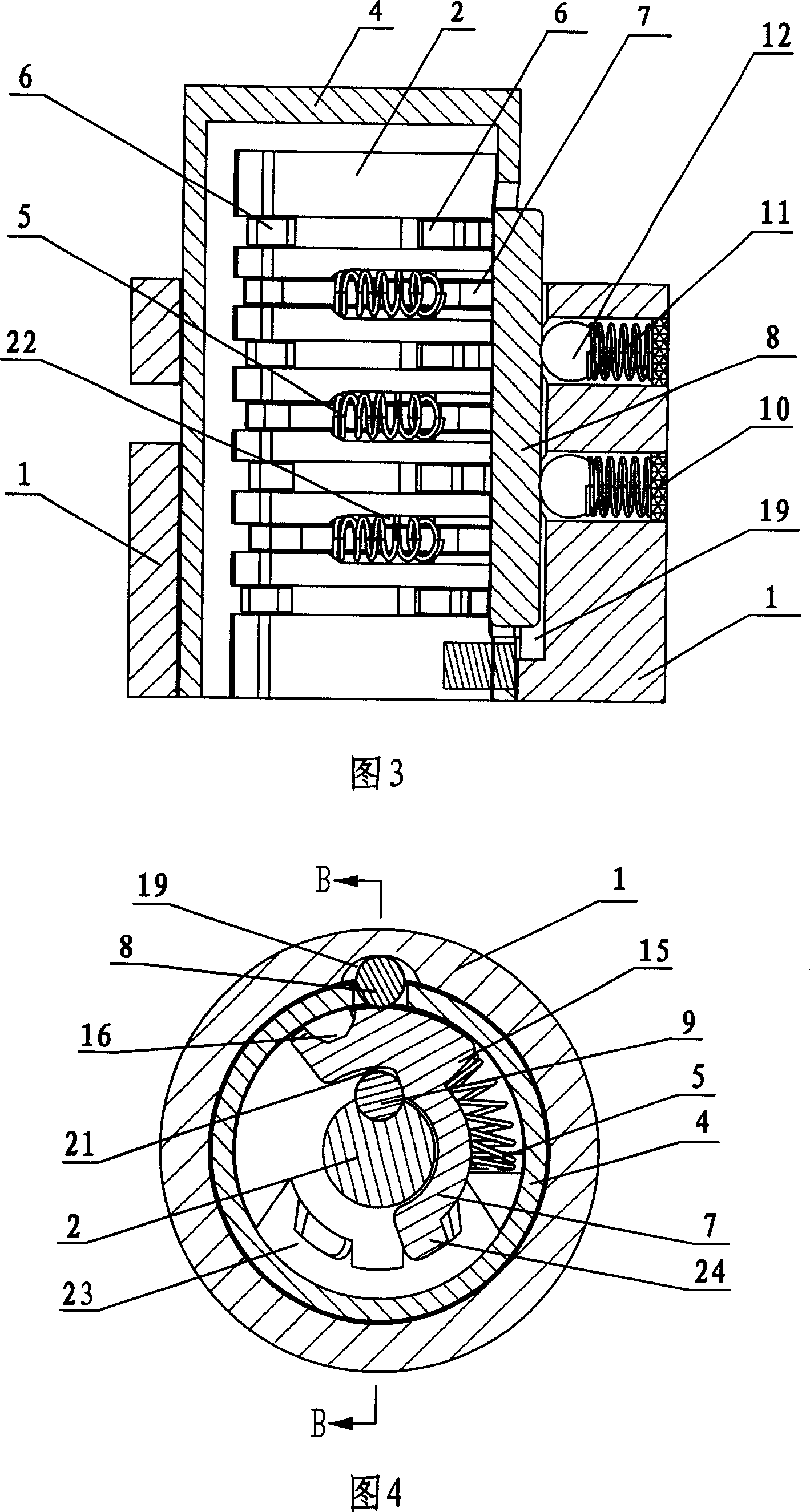

[0017] As shown in the figure: a lock head device of the present invention comprises a lock housing 1, a cylindrical middle housing 4 in the lock housing 1, a cylindrical lock core 2 in the middle housing 4, and the outer surface of the lock core 2 is provided with multiple The strip is perpendicular to the annular groove 13 of the central axis of the lock cylinder 2, and the surface of the lock cylinder 2 has a lock cylinder edge retainer groove 18 parallel to the axial direction of the lock cylinder 2, and the lock cylinder edge retainer groove 18 is located in the middle of the surface of the annular groove 13 , The middle shell 4 and the corresponding position of the lock shell 1 are respectively provided with a middle shell side stop groove 17 and a lock shell groove 19, and a cylindrical side stop 8 is arranged therein.

[0018] Each annular groove 13 is provided with an arc-shaped leaf 6, 7 and a leaf spring 5, and the leaf 6, 7 includes a left leaf 6 and a right leaf 7,...

Embodiment 2

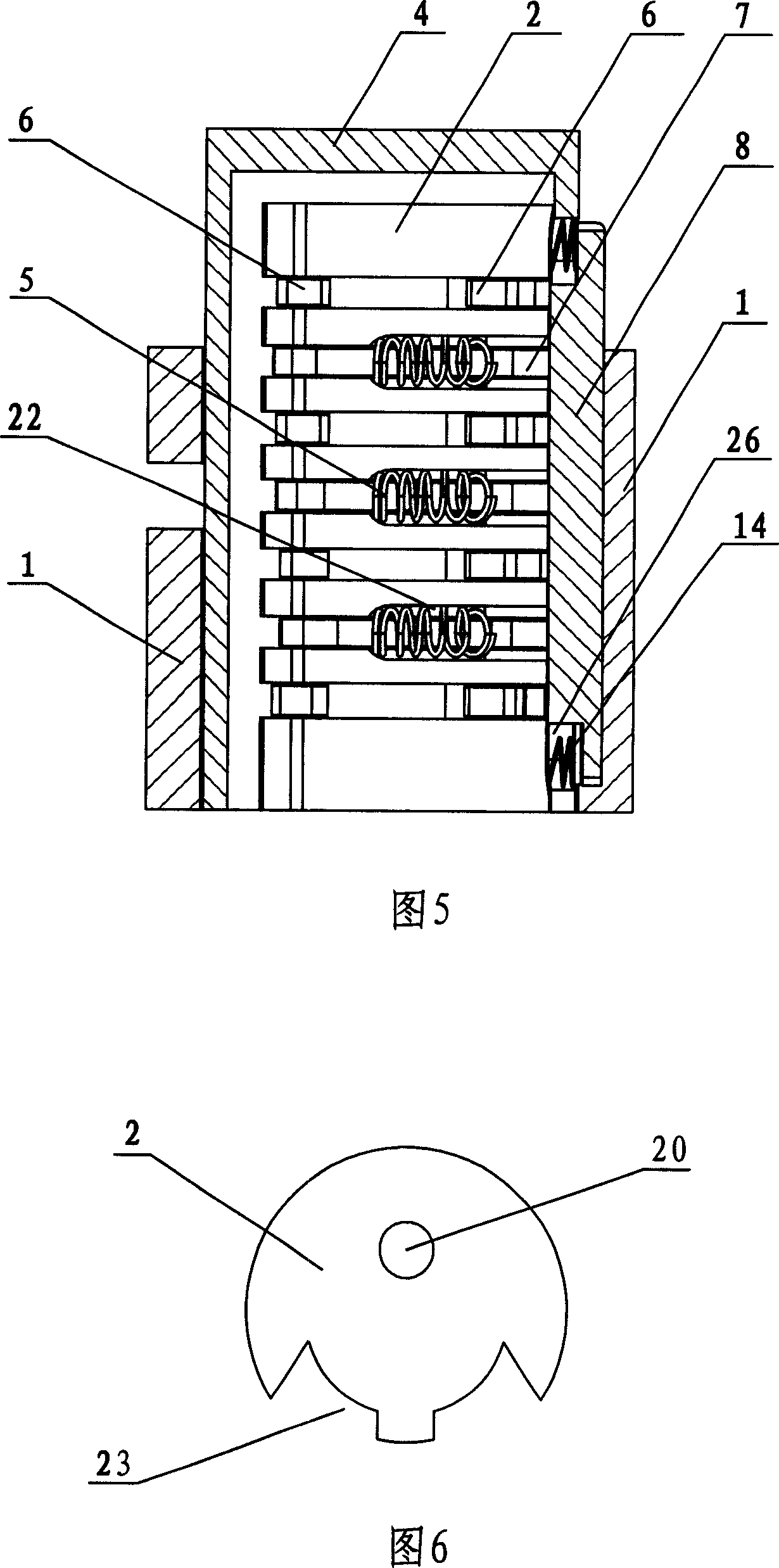

[0024] As shown in Fig. 4 and Fig. 5: a lock head device of the present invention includes a lock case 1, a cylindrical middle case 4 inside the lock case 1, a cylindrical lock core 2 inside the middle case 4, and an outer body of the lock core 2. The surface is provided with a plurality of annular grooves 13 perpendicular to the central axis of the lock cylinder 2, and the surface of the lock cylinder 2 has a lock cylinder side stopper groove 18 parallel to the axial direction of the lock cylinder 2, and the lock cylinder side stopper groove 18 is located on the surface of the ring groove 13. At the middle position of the middle shell 4 and the corresponding position of the lock shell 1, a middle shell edge retainer groove 17 and a lock shell groove 19 are respectively provided. The edges of the lock shell groove 19 transition smoothly, and there is a cylindrical edge Baffle 8; each annular groove 13 is provided with an arc-shaped leaf 6,7 and a leaf spring 5, and said leaf 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com